Pin mixers are used in a variety of industrial settings to mix, condition, and agglomerate materials, as well as to prepare them for pelletizing. No matter what setting they are in, or what objective they are performing, optimizing pin mixer performance and promoting equipment longevity is essential.

Pelletizing plants should follow the best practices below to maximize gains when employing a pin mixer.

About Pin Mixers

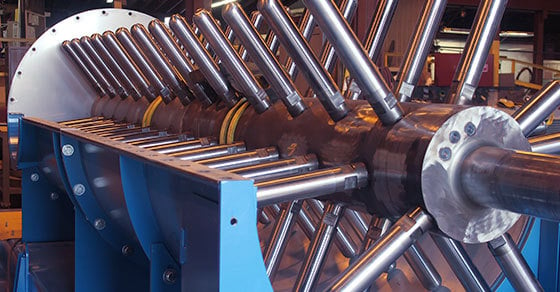

Pin mixers are a type of horizontal industrial mixer used in continuous production settings. Often categorized under agglomeration equipment, these diverse machines are capable of carrying out several process objectives, including preconditioning feed for a pelletizing process, producing micro pellets, creating a uniform mixture from disparate liquid and solid feeds, as well as conditioning dusty materials.

The pin mixer consists of a rotating shaft housed in a cylindrical chamber. The shaft is fitted with several rods or “pins,” which, upon rotation, cause an intense spinning action within the sealed chamber. A spray system feeds ports going into the mixer to distribute the liquid component or binder at predetermined locations and rates.

3D Model of a FEECO Pin Mixer

Pin mixers have become an integral production component in many industrial processes. Common pin mixer applications include de-dusting coal fines and other dusty materials, processing ultra-fine materials such as pigments and dyes, and preconditioning materials such as limestone and gypsum for soil amendment production.

Best Practices for Optimal Pin Mixer Operation

Whether looking to purchase a pin mixer, or improve an existing operation, the following recommendations provide high-level considerations for achieving the most gains in operations employing a pin mixer.

Utilize a Variable Frequency Drive (VFD)

A variable frequency drive, or VFD, is an alternative to a fixed-speed motor that allows operators to adjust motor speed as needed. This is useful during start-up in order to fine-tune the product.

A VFD also allows operators to adjust speed in response to changes in production, promoting more fluid operation less susceptible to process upsets during times of fluctuation.

Because motor speed is being adjusted in accordance with start-up and shutdown, a VFD also minimizes mechanical strain and promotes a longer motor life.

Allow Multiple Binder Injection Ports

The pin mixer is often chosen for its ability to combine liquid and solid feedstocks into a homogeneous mixture. The success of this is in large part because of an optimized spray system.

By using multiple spray ports, operators have the flexibility to experiment with spray location during start-up. Similarly, if variation in the feedstock occurs, operators are able to adjust the spray system as needed to accommodate the change.

Operators struggling with product uniformity or inconsistent production may benefit from the addition of more spray ports.

Maintain a Consistent Feed

The more uniform the feedstock, the more uniform the product. This statement is true of many types of industrial processing equipment, and the pin mixer is no exception. Variation in feedstock may occur for several different reasons and identifying the source of variation is critical to abating it.

While pin mixers provide operators the opportunity to adjust process parameters in response to changes in feedstock, the more uniform the feedstock, the less the operator will have to adjust and the lower the potential for variation in product quality and output.

Feedstock characteristics that should be kept as uniform as possible when utilizing a pin mixer include:

- Moisture content

- Chemical composition

- Particle size distribution

It’s important to recognize also that pin mixers are not the ideal mixer choice when tramp material or large clumps of hard material entering the process are common, as these have the potential to break off pins or cause damage to the mixer shaft.

Look at the Whole Process

While it may be tempting to look at a pin mixer in isolation, to realize the most gains, the mixer should always be considered as part of the larger process. This is true of both general operational efficiency and during troubleshooting.

A properly functioning process is a careful balance of each component in the system; when one variable falls out of balance, other parts of the process are affected. The effect may not be obvious or cause an immediate problem, but it does occur.

As such, changes or fluctuations upstream of the mixer are likely to have an effect on mixer performance and must be considered as a potential cause during troubleshooting. Issues occurring in the end product could also be tied to pin mixer operation.

Similarly, operators looking to optimize the process must look at each process component as part of the larger whole.

Keep Buildup to a Minimum

It is best practice to keep buildup to a minimum in any industrial processing device, but it is especially important for pin mixers, due to the intense spinning action that occurs in the unit.

Buildup not only reduces mixer performance and efficiency, but it also promotes increased wear on the mixer’s internals and motor. It also risks promoting excessive abrasive wear and damaging the equipment, particularly when processing materials with cementitious properties, such as gypsum, as the buildup could harden in place.

Use a Self-Raising or Clamshell Cover

Depending on the size of the pin mixer, different cover options may be available. For smaller machines, a clamshell design can be used to facilitate easier opening of the cover. Larger mixers can utilize a self-raising cover to improve access to the mixer’s interior. Opting for a clamshell or self-raising cover on the pin mixer may seem an unnecessary expense, but saves significant time in the long run.

The pin mixer chamber is constructed by bolting together a top and bottom half. In the event that operators or maintenance personnel need to inspect or make changes to the mixer’s interior, the top half must be unbolted and a hoist used to pick up and remove the top half. This is not only time consuming, but it is also a challenge for operations limited on space, or that don’t have a beam available above the mixer to connect the hoist to.

With a self-raising or clamshell cover design, the operator need only unclamp the top portion of the mixer. With the clamshell design, the top portion opens upwards and the bottom portion opens downwards. With the self-raising cover, the bottom portion of the chamber remains stationary, while electric actuators raise the top half.

This upgrade in cover design significantly reduces the time and labor involved in accessing the mixer’s interior, allowing operators to quickly inspect or repair the unit and get it back in operation in minimal time.

Take Advantage of Automation

Pin mixers are easily automated and offer significant value as such. When paired with an automation system, process variables can be collected, reported, and adjusted in real-time – all from a single user interface. This not only streamlines process adjustments, but it also gives operators the transparency they need to predict and prevent potential problems, quickly resolve issues, and even trend data for predictive maintenance. A number of variables can be tracked and trended on a pin mixer, including:

- Current (amps)

- Feed & product rates

- Flow rates

- Horsepower

- System pressures

- Temperature

- Torque

Consider Testing

The many variables in a production setting can make consistent pin mixer performance seem elusive, particularly when working with a novel process. When variation in feedstock occurs, this inconsistency is further exacerbated.

For these reasons, FEECO often recommends testing in a facility such as the Innovation Center. Here, experts run batch and pilot-scale tests to assess the feasibility of an intended operation, as well as to work out process variables to optimize the process and streamline production.

The data gathered can then be used to design a commercial-scale unit or retrofit an existing one to suit the process requirements.

Utilize Toll Processing When Available

When developing a new process, producers should take advantage of tolling services where available. Tolling is often used as an extension of the testing and process development journey, further derisking scale-up. It is often used to produce market samples or initial production capacity. This allows producers to see their process in action on a larger scale, and address any unexpected scale-up issues that arise.

The FEECO Tolling Center offers pin mixer tolling in a variety of potential configurations, including micro pelletizing, conditioning, and preconditioning material as part of a larger agglomeration process.

Conclusion

Pin mixers are an effective solution in achieving many process objectives, but optimizing their performance and promoting equipment longevity is no accident.

For best results and maximum efficiency, consider best practices such as using a VFD, opting for multiple injection ports, maintaining a consistent feed, and the other aspects discussed here.

FEECO pin mixers are the industry standard for an array of applications. Our in-house testing facility reveals optimal processing conditions and allows us to design and fabricate each mixer around the unique specifications of the material to be processed. For more information on FEECO pin mixers or other agglomeration equipment, contact us today!