The sealing mechanism on a rotary dryer, kiln, or granulator is essential to maintaining optimal performance and efficiency. As a result, the replacement of worn seals can often improve process efficiency and reduce fuel costs, among other benefits.

AVAILABLE SEALS

FEECO offers the following seal options:

labyrinth seal

Relative Leakage >> 5.0%

The labyrinth seal is a cost-effective option when air leakage into the system is not a major concern. This seal provides a tortuous path for the ambient air by means of relatively close clearance between the rotating seal ring and the non-rotating housing. Sealing can be improved with the addition of a flexible wrap between the seal plate and rotating shell.

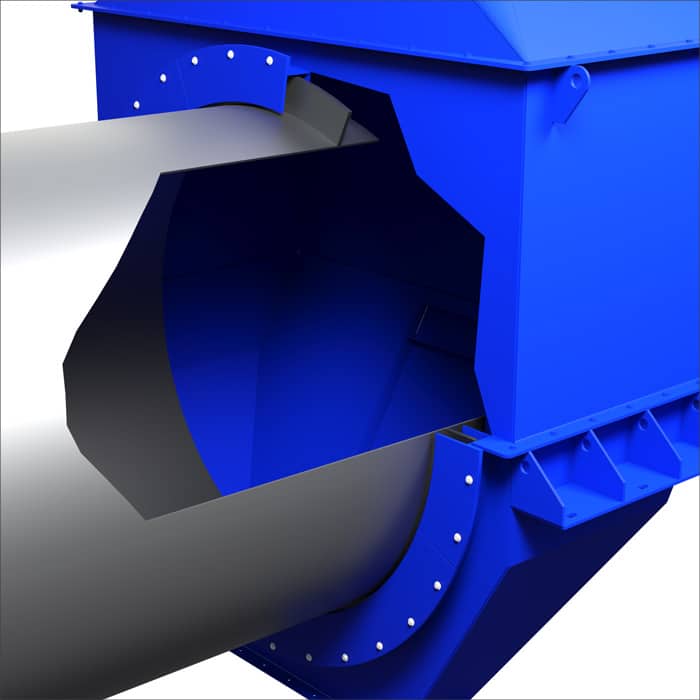

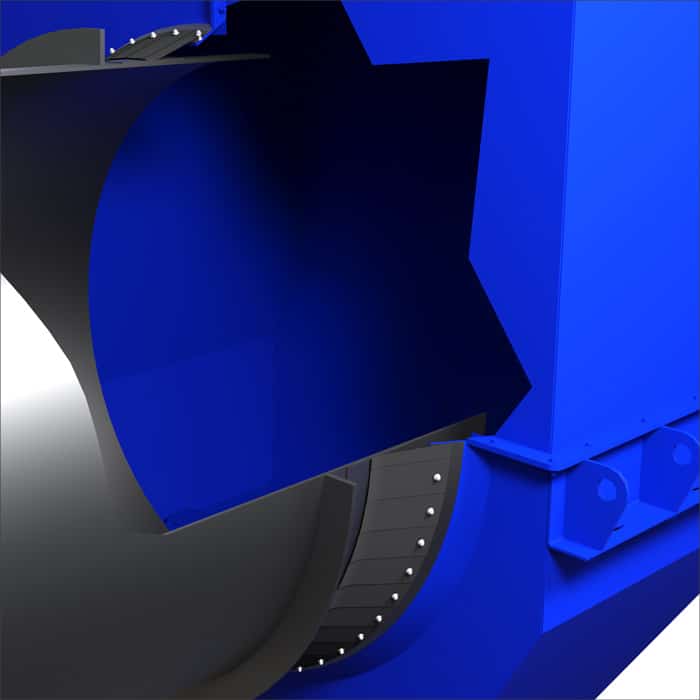

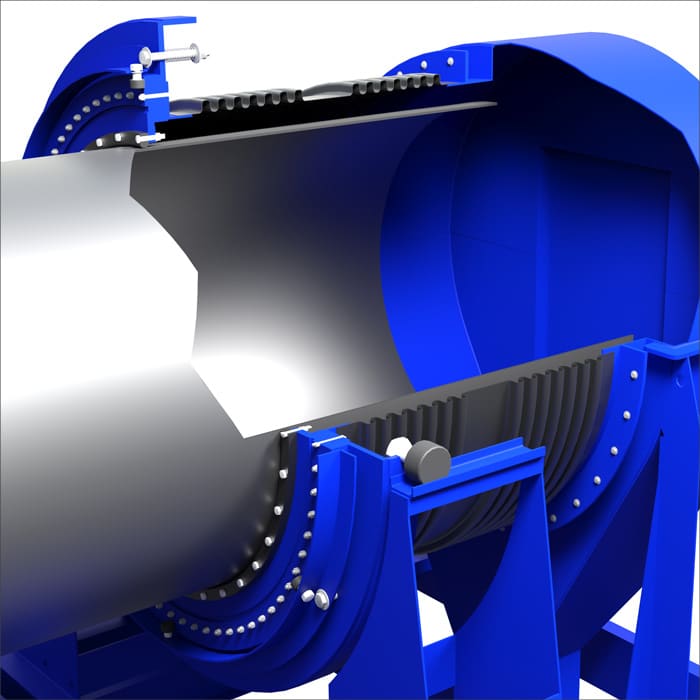

SINGLE AND DOUBLE LEAF SEALS

Single Leaf Seal Relative Leakage << 3.0% to 5.0%

Double Leaf Seal Relative Leakage << 1.0% to 3.0%

The single leaf seal (shown) is the seal of choice to minimize the leakage of air into the dryer or kiln. Limiting leakage reduces fuel consumption and can result in a capacity increase. The seal consists of a series of overlapping spring steel plates that are mounted to the housing and ride on a wear ring on the rotating shell.

Also available, the double leaf seal is used when less leakage can be tolerated than with the single leaf seal. The double leaf consists of two leaf seals with a ceramic fiber blanket sandwiched between the two leaves. Leakage is about 25% of a single leaf.

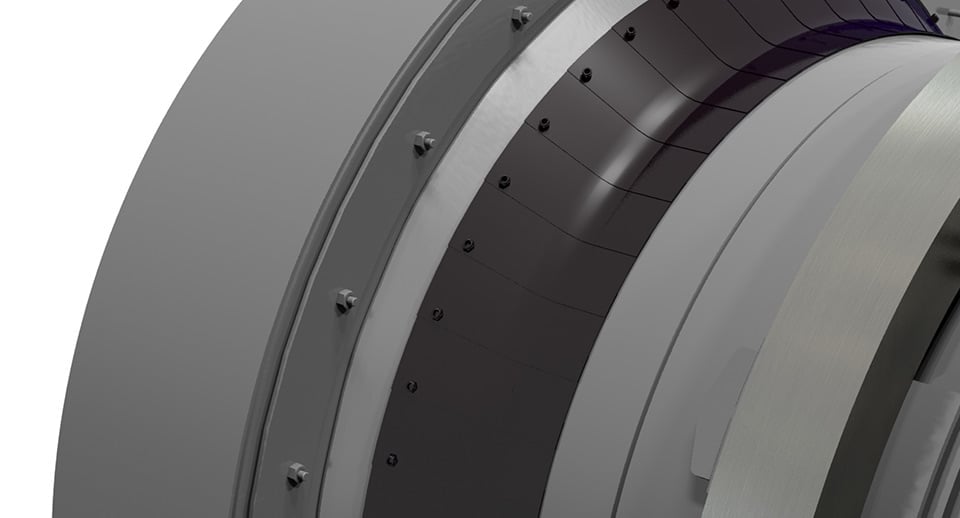

BELLOWS SEAL

Relative Leakage = << 1.0%

The bellows seal utilizes a wear material, such as graphite, to act as a face seal when compressed against a flat, rotating surface. The corrugated bellows accommodates significant longitudinal expansion—especially useful for higher temperature drums such as indirect kilns. The bellows is guided and supported by cam rollers.

INDICATIONS THAT A SEAL NEEDS REPLACEMENT

Visible wear, such as missing or worn leaves, as well as chattering or vibration, can be signs that a seal is worn and may require replacement.

Additionally, unexplained process inefficiencies can also be a sign that seal performance has degraded.

Contact our Customer Service Team for a quote on a replacement seals or other rotary drum parts.

RESOURCES

SEAL ARTICLES

Seal Options for Rotary Dryers and Kilns

Rotary dryers and kilns are an integral part of the many industrial processes that shape our world. From fertilizer and chemical …

FEECO’s leaf seals are designed to minimize air leakage into a rotary dryer or rotary kiln. We offer both single and …