DIRECT ROTARY DRUM DRYERS

We’ve built a reputation on being the best rotary dryer manufacturer in the industry. All of our dryers are custom designed to suit the unique processing needs of your material. Whether you require low- or high-inlet temperatures, short or long residence times, counter-current or co-current flow, FEECO’s design team can design a rotary drum dryer for your application.

Rotary dryers are a highly efficient industrial drying option for bulk solids. They are often chosen for their robust processing capabilities and their ability to produce uniform results despite variance in feedstock.

Rotary dryers work by tumbling material in a rotating drum in the presence of a drying air. They can also be indirectly heated to avoid direct contact between the material and processing medium.

The drum is positioned at a slight horizontal slope to allow gravity to assist in moving material through the drum. As the drum rotates, lifting flights pick up the material and drop it through the air stream in order to maximize heat transfer efficiency. When working with agglomerates, the tumbling action imparted by the dryer offers the added benefit of further rounding and polishing the granules.

FEATURES

- Diameter: 3′ – 15′ (1 – 4.6m)

- Capacity: 1 TPH – 200 TPH (1 MTPH – 181 MTPH+)

- Specially designed lifting flights to maximize heat transfer between the material and hot gas stream

- Heavy duty design and construction for many years of service

- Co-current (parallel flow) or counter-current configuration

- Process and Mechanical Warranties

- Various Drive Assemblies Available

Optional Components

- Knocking Systems

- Trommel Screen

- Liners

- Leaf Seals

- Graphite Seals

- Machined Bases

- Screw Conveyor Feeder

- Automatic Gear Lubrication System

- Exhaust Handling Equipment

- Ductwork

Material Options

- Carbon Steel

- Stainless Steel

- Specialty Alloys

- Explosion Bonded

- AR Steel

Accommodates Various Fuel Types

- Fuel Oil

- Natural Gas/Propane

- Waste Heat

- Biogas

We can offer cost competitive designs for pilot scale units that process as little as one ton per hour to heavy duty units in excess of 17 foot in diameter that process hundreds of tons per hour.

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

DIRECT ROTARY DRUM DRYER COMPONENTS AND PARTS

The image below shows the standard components of a rotary dryer. Click image to view larger.

A – Burner

B – Combustion Chamber

C – Raw Material Feed Chute

D – Riding Ring/Tire

E – Gear/Sprocket Guard

F – Flights

G – Exhaust Handling System

H – Discharge Breeching

I – Product Discharge

J – Drive Assembly

K – Drum Shell Riding Ring

L – Graphite Block Lubrication Assembly

M – Trunnion Wheel

N – Trunnion Guard

O – Pillow Block Bearing

P – Thrust Roller Assembly

Q – Coupling Guard

R – Gear Reducer

S – Pinion Gear

T – Girth Gear

For more detailed component descriptions, see the Rotary Dryer Parts and Components Glossary.

APPLICATIONS & MATERIALS

Rotary dryers are known as the workhorse of industrial dryers. They are able to process a wide variety of materials, and can lend a hand in nearly any industry requiring industrial drying solutions. Some of the most common industries and materials in which FEECO rotary dryers are employed include:

- Aggregates

- Agricultural By-Products

- Animal Feeds

- Biosolids (Municipal Sewage Waste & Sludge)

- Catalysts

- Fertilizers

- Fly Ash

- Gypsum

- Inorganic Chemicals

- Limestone

- Manure

- Metal Chips & Shavings

- Mining Ores & Concentrates

- Organic Chemicals

- Paper Sludge

- Plastic Pellets & Grains

- Potash

- Reclaimed Dust

- Roofing Granules

- Rubber Pellets

- Salts & Sugars

- Sand

- Steel Mill Waste Sludges

- Urea Prills & Crystals

INDIRECT ROTARY DRUM DRYERS

Unlike direct dryers, indirect dryers do not rely on direct contact between the material and process gas to dry the material. Instead, the rotating drum is enclosed in a furnace, which is externally heated. Contact with the heated drum shell is what dries the material.

While indirect dryers are less efficient compared to their direct counterparts, they offer some advantages that can make them an attractive alternative. This includes:

FEATURES

- Diameter: 3′ – 15′ (1 – 4.6m)

- Capacity: 1 TPH – 200 TPH (1 MTPH – 181 MTPH+)

- Specially designed lifting flights to maximize heat transfer between the material and hot gas stream

- Heavy-duty design and construction for many years of service

- Process and Mechanical Warranties

- Various Drive Assemblies Available

Optional Components

- Knocking Systems

- Trommel Screen

- Liners

- Machined Bases

- Screw Conveyor Feeder

- Automatic Gear Lubrication System

- Exhaust Handling Equipment

- Various Burner Configurations

- Various Seal Options

- Ductwork

Material Options

- Carbon Steel

- Stainless Steel

- Specialty Alloys

- Explosion Bonded

- AR Steel

Accommodates Various Fuel Types

- Fuel Oil

- Natural Gas/Propane

- Electricity

- Waste Heat

- Biogas

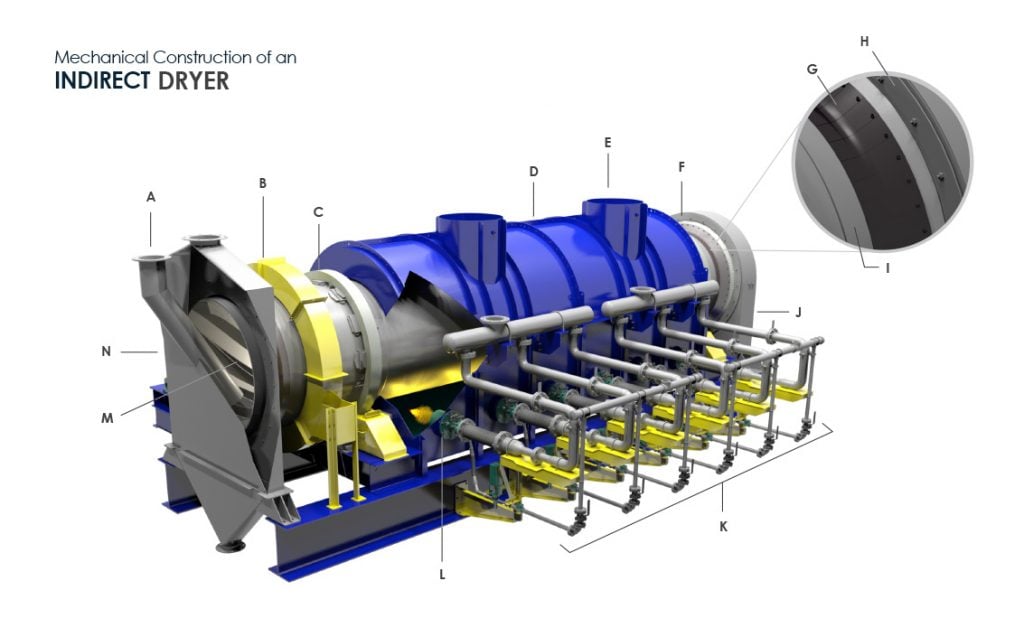

INDIRECT DRUM DRYER COMPONENTS AND PARTS

The image below shows the standard components of an indirect rotary dryer. Click image to view larger.

A – Material Inlet

B – Gear/Sprocket Guard

C – Riding Ring

D – Furnace

E – Exhaust Vent(s)

F – Air Seal

G – Spring/Leaf Seal

H – Seal Mounting Flange

I – Seal Wear Surface

J – Discharge Breeching

K – Gas and Air Piping

L – Burners

M – Advancing Flights

N – Inlet Breeching