DISC PELLETIZERS

FEECO’s Disc Pelletizers (also known as pan granulators) are the equipment of choice for converting powdered materials into uniform, round pellets.

Disc pelletizers utilize a non-pressure (tumble growth) approach to agglomeration and work by tumbling material on a rotating disc, with a binding agent and feedstock being continuously added. The binding agent causes the fines (or seed pellets, when utilizing a pre-conditioning step) to become tacky and pick up additional fines as the material tumbles against itself. This causes a “growing” action referred to as coalescence. Once pellets have reached the desired size, they exit the rotating disc via centrifugal force.

FEATURES

- Size: 6′ – 25′ (1.8 – 7.5m)

- Capacity: 1 TPH – 140 TPH

- 6’ (1.8m) and larger discs are lined with expanded metal to reduce abrasive wear.

- A hand-wheel operated jacking screw allows for easy adjustment of disc angle.

- The base and plow support members provide maximum rigidity, while simultaneously allowing rapid disc angle adjustment, without the need for separate plow adjustment.

- Individually mounted vane-type plows easily control and maintain the product layer over the disc’s entire surface.

- The pivot base is mounted on heavy-duty, anti-friction bearings. Automatic lubrication is featured on larger discs.

Optional Components

- Reciprocating Scraper

- Partial Hood

- Full Hood

- Stainless Steel Construction

- Variable Frequency Drive

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

DISC PELLETIZER COMPONENTS AND PARTS

The image below shows the standard components of a disc pelletizer. Click image to view larger.

Mechanical Construction of a Disc Pelletizer (3D Pelletizer by FEECO International)

A – Spray System

B – Angle Adjustment

C – Pivot Bearings

D – Stuctural Steel Base

E – Discharge Chute

F – Pan/Disc Assembly

G – Plow/Scraper Assemblies

H – Mounting Hub

I – Gear Reducer

J – Drive Belt & Pulley

K – Drive Motor

WHAT CAN PELLETIZING DO FOR YOUR MATERIAL?

Pelletizing, like all types of agglomeration, offers a variety of benefits. Among them, it allows you to:

- Reduce Volume

- Stabilize Mixtures During Handling

- Eliminate/Reduce Dust Problems

- Control Hardness

- Reduce Packing, Storage and Transport Costs

- Improve Product Performance

- Improve Handling

To learn more about how agglomeration can benefit your material, see Why Agglomerate Your Material.

APPLICATIONS & MATERIALS

FEECO’s Disc Pelletizers can agglomerate everything from fine, dry feed materials, all the way to wet, sludge-like materials. Some of the most common applications for which pelletizer plants are built include:

- Chemical Powders

- Limestone / Gypsum

- Fertilizers

- Coal fines

- Cement / Lime Kiln Dust

- Flyash

- Filter / Centrifuge Cake

- Minerals and Ores

- Vibrating Sludges

- Pond tailings

- EAF Dust

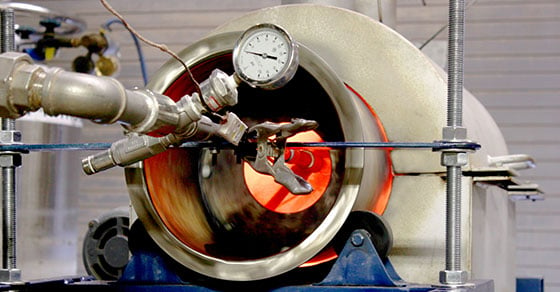

MATERIALS TESTING FACILITY

Laboratory and pilot scale tests conducted in the FEECO Innovation Center can determine optimum flow schemes, equipment sizing, and scale up. If lab tests reveal that alternative agglomeration methods such as briquetting or compaction is the method of choice, FEECO can accommodate these processes as well.

If agglomeration with a disc pelletizer is the method of choice, further savings can be realized with lower investment, power consumption, and maintenance costs.

RESOURCES

DISC PELLETIZER ARTICLES

R&D Around Catalyst Manufacturing Sees Growth

As the role of catalysts in industry continues to grow, catalyst manufacturing research and development continues to rise. In this effort, …

Catalyst Pelletizing for Enhanced Performance and Longevity

Catalyst size and shape play a crucial role in optimizing reaction efficiency. As the chemical industry pushes for more effective processes, …