R&D Around Catalyst Manufacturing Sees Growth

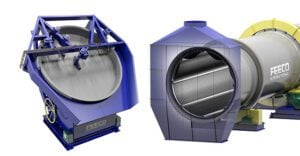

As the role of catalysts in industry continues to grow, catalyst manufacturing research and development continues to rise. In this effort, the FEECO Innovation Center serves as a critical testing environment for producers looking to improve existing products or develop new ones. The following looks …