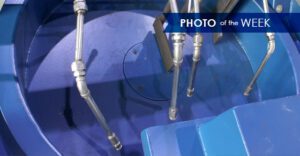

What does a Micro-Pelletizing Setup Look Like?

Micro-pelletizing can be carried out in a pin mixer, or in a pin mixer/disc pelletizer (pan granulator) combination. Pin mixers alone often provide efficient results when full-scale pelletizing is not necessary, or when only smaller pellets or conditioning is needed. To begin, the pin mixer …