When designing a gypsum pelletizing system, most attention focuses on larger equipment such as disc pelletizers or rotary dryers. However, the importance of a pin mixer for gypsum pelletizing should not be overlooked.

Pin mixers offer numerous benefits such as solids mixing, densification, and granulation. As a result, the incorporation of such can play a critical role in producing the best final gypsum product, while also improving processing productivity.

How A Pin Mixer Works

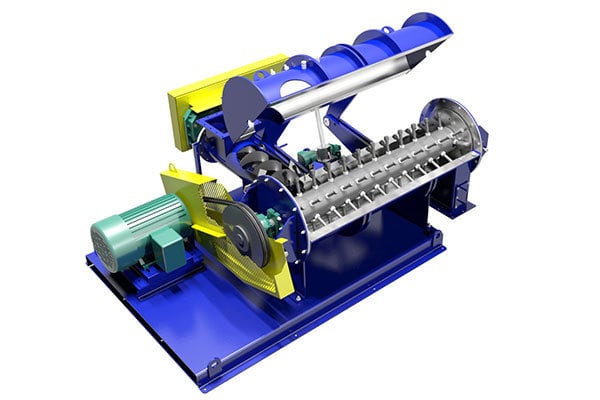

FEECO’s pin mixer features a central rotor shaft housed in a stationary shell. The shaft extends the entire length of the mixer, with multiple pins extending outward. Using a constant speed motor, the shaft is spun at a high velocity exceeding several hundred RPMs. The rotational speed is pivotal to how this type of mixer works, because this motion imparts agitation forces on the gypsum and binder material. The intense spinning action eliminates air, reduces water volume between material particles, and results in material densification greater than what can be achieved with a disc pelletizer.

Uses and Application Solutions

Adding a pin mixer to gypsum processing systems is beneficial for many different uses and solutions, among them:

Pre-Conditioning for Pelletized Gypsum

Pin mixers are often used to a pre-condition gypsum before the material is fed into a disc pelletizer, evenly distributing binder, creating an easy to handle material, and providing more control on the disc pelletizer. It also allows a higher throughput, a reduction in the amount of binder required, and produces more high-quality, consistently sized gypsum pellets.

De-Dusting

Pin mixers are an excellent choice for de-dusting applications. For example, the gypsum pelletizing process starts with powdered gypsum that is very dusty. This material is difficult to handle and results in unintended material waste. By first blending powdered gypsum with a binder, the resulting mixture becomes nearly dust free, easier to handle, and optimally preconditioned for pelletization on a disc pelletizer.

Improved Productivity

The FEECO pin mixer can produce more in the way of densification with less binder and much less horsepower than any other agglomeration equipment. By creating a better mixture, manufacturers have an opportunity to increase production. Subsequent gypsum processing steps that follow a pin mixer require less time because the mixture is already uniformly combined. Pin mixers are also ideal components in an automated system, offering precise quality control and accurate production rates.

FEECO has been customizing gypsum processing equipment such as pin mixers for more than 65 years. For more information on our pin mixers or other industrial mixing solutions, contact us today!

Click the image below to view our infographic on gypsum soil amendments