Benefits of Agglomeration in an SX-EW Process for Improved Copper Extraction

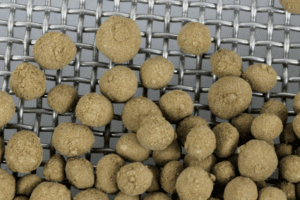

Agglomeration, typically carried out via drum agglomerator, has become a pivotal technology in modern copper extraction, as the Solvent Extraction Electrowinning (SX-EW) process is increasingly employed for low-grade sulfide ores, tailings, and oxide ore bodies. As demand for copper grows and these low-grade sources become …