While agglomeration is most often considered as a means to a product’s end, in some cases, it also frequently serves as an important stepping stone behind the scenes in the production of other materials and products.

In these cases, agglomeration, or pelletizing, is a vital tool, particularly when it comes to maximizing the flow of liquids or gases through a bed of material; by agglomerating fines into rounded pellets through the use of disc pelletizers (pan granulators) or drum granulators, producers can maximize bed permeability and distribution of the liquid or gas through the solids bed.

Why Bed Permeability is Important

There are numerous industrial processes which rely on passing liquids or gases through a bed of material. This may be to recover a valuable component, remove a contaminant, or to elicit a chemical reaction that produces a new or modified material.

In these scenarios, bed permeability, or how well the liquids or gases can pass through the bed, becomes critical to achieving the process goal and doing so efficiently. The gas or liquid must be able to be evenly distributed throughout the bed of solids; were only a portion of the bed in contact with the medium passing through it, the remainder of the bed would be largely unprocessed.

This could result in a number of consequences, including a low rate of recovery (and in some cases, a high rate of material that cannot be reprocessed), increased fuel costs, higher reductant requirement, and more.

How Agglomeration Improves Bed Permeability

Optimal particle and bed characteristics vary depending on the goal, but in general, round granules promote the most uniform penetration of a bed of solids.

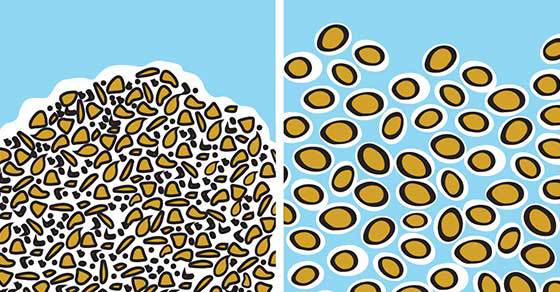

This is because round, uniformly sized pellets create a network of open spaces between particles, allowing the gas or liquid to flow easily throughout the bed. In contrast, when particles are not agglomerated, smaller particles tend to fill in the spaces between larger particles, blocking the flow of material, as shown in the image below.

Similarly, jagged, irregular granules can produce “clogging,” as the angular edges fit together, blocking flow.

Industrial Processes That Rely on Rounded Granules

There are a number of different processes that employ agglomeration in this way, particularly in the case of pyrometallurgical and hydrometallurgical treatments. A few examples are provided here.

Agglomeration for Pyrometallurgical Treatment

Pyrometallurgical processes use heat to remove impurities from metallic ores and concentrates, leaving the target metal behind. Pelletizing is often used in preparation of the furnace or kiln as a way to improve bed permeability, as well as reduce particle entrainment.

In this setting, bed permeability promotes efficient energy use and maximum metal recovery by ensuring the gases can come in contact with as much surface area as possible, without risking entrainment.

This can contribute significantly to the overall efficiency of an operation, and also helps to minimize unnecessary waste. Common examples of how this concept is applied include:

- EAF dust recycling

- Iron ore balling for steel production

- Nickel dust recovery

- Zinc roasting preparation

Pelletized iron ore

Agglomeration in the Heap Leaching Process

Another prime example of how agglomeration contributes to bed permeability is in heap leaching – a hydrometallurgical process used to recover metals from ores.

Here again, agglomeration promotes more uniform particle size to minimize the potential for fines to clog space. This improves percolation of the leachate through the ore pile for maximum recovery of the target metal.

In addition, agglomeration in this setting also provides the opportunity to pre-mix the ore with the leaching agent, which maximizes the contact between ore and leachate, and gives the leaching process a head start.

This technique is commonly used in processing copper and gold, as well as:

- Uranium

- Nickel

- Silver

- And more

Other Benefits of Agglomerated Bed Materials

In addition to improved bed permeability, agglomeration can lend a number of other benefits to such operations as well. The potential benefits of agglomeration will depend on the specific operation, but often include:

- Reduced dust during handling and processing

- Improved target component recovery

- Improved heat transfer

- Reduced fuel use (due to improved gas-to-solids contact)

- Lower reductant requirement

- Expanded source material inclusion

- Greater control over bed particle characteristics

Bed Permeability in End Products

In addition to industrial processes employing agglomeration to improve bed permeability, it’s worth noting that agglomeration is also widely used in this way in a variety of end products as well; catalyst carriers, adsorbents, filter agents, desiccants, and more, often rely on bed permeability in order to effectively carry out their specific purpose.

Agglomeration Equipment

Depending on the material and the specific goals of agglomeration, several different devices may be used in singularity or in combination to produce the desired agglomerates.

It’s important to recognize that other types of agglomeration are also sometimes employed in this effort, the choice between which depends on the project goals, material specifications, and more.

In producing round pellets, the two most common types of equipment used are the disc pelletizer (pan granulator) and agglomeration drum, or agglomerator, both in the family of agitation agglomeration equipment.

Disc Pelletizer (Pan Granulator)

The disc pelletizer, also known as a pan granulator, is a continuous device that consists of a rotating disc set on a stationary base. Liquid binder and feed material are continuously fed onto the disc. The binder causes fines to become tacky, collecting other fines, while centrifugal force causes the particles to travel up the disc’s edge and cascade down its face, a tumbling motion that promotes granule formation and layering growth.

3D Rendering of a FEECO Disc Pelletizer

The disc pelletizer is preferred for its tight particle size control (a number of variables can be adjusted during operation), as well as the refined pellet product it yields.

Agglomeration Drum (Agglomerator)

The agglomeration drum, or agglomerator, is a rotary drum that works on a similar principle: fines are tumbled in the drum in the presence of a liquid binder, causing particles to aggregate and densify.

3D Rendering of a FEECO Agglomeration Drum

This device is chosen because it is a sealed system and offers a high throughput, but it does not have the particle size control capabilities of the disc pelletizer.

Both types of equipment yield rounded pellets suitable for use as a permeable bed.

Evaluating Agglomeration

FEECO offers the ability to evaluate agglomeration for a given material at both batch and pilot scale in our Innovation Center, where various types of agglomeration equipment are available for testing and process development, including disc pelletizers and an agglomeration drum.

These capabilities give producers the opportunity to confirm feasibility of an intended process, as well as identify the most suitable equipment, while also gathering the process data necessary for scale-up.

Samples can also be produced for additional testing.

Conclusion

Though most widely recognized for its use in end products, pelletizing also plays an important role in allowing producers to create the conditions necessary to produce or recover other products by promoting maximum bed permeability for liquids and solids. This technique is especially useful in pyrometallurgical and hydrometallurgical processes where it offers a number of other benefits as well.

FEECO has been providing custom disc pelletizers and agglomeration drums for this purpose since 1951. Our testing facility is equipped to test agglomeration in various types of equipment to confirm feasibility and produce samples, as well as to develop a process to commercial scale. For more information on our capabilities, contact us today!