Ensuring A Smooth Rotary Drum Installation

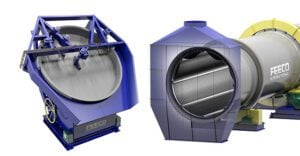

A rotary drum, be it a dryer, cooler, agglomerator, or otherwise, is a major investment and integral part of many industrial processing systems. From drying and cooling bulk solids before storage, to agglomerating ore fines in a heap leaching operation, the rotary drum often serves …