ROTARY CALCINERS

Rotary calciners, also commonly called indirect kilns, are used in various calcination operations where exhaust gases must be minimized, when processing finely divided solids, or where temperature must be tightly controlled along the length of the kiln.

A calciner is comprised of a rotating drum inside a furnace, which is externally heated. Unlike direct-fired kilns, which utilize direct contact between the material and process gas to carry out processing, in a calciner, heat is transferred from the shell of the externally heated kiln to the bed of material through radiation.

FEECO offers a unique testing facility where we use batch and continuous pilot equipment to simulate production conditions, allowing us to test small samples of your material under various conditions and develop a process around the unique needs of your material. Specifically, we offer a direct batch kiln, indirect batch kiln, direct continuous kiln, and indirect continuous kiln.

The batch and pilot direct-fired equipment can be configured to include the following: combustion chamber, afterburner, baghouse, quench chamber, and wet scrubber.

ROTARY CALCINER COMPONENTS AND PARTS

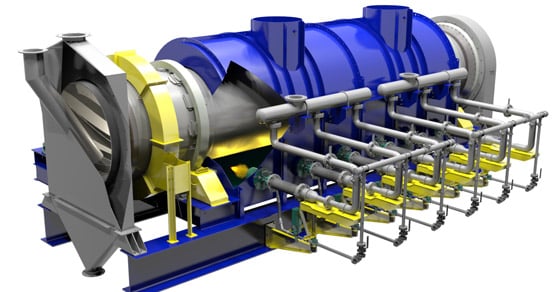

The image below shows the standard components of a calciner. Click image to view larger.

Mechanical Construction of a Calciner (3D Calciner by FEECO International)

A – Material Inlet

B – Drive Gear Guarding

C – Riding Ring

D – Heat Shroud

E – Exhaust Vent(s)

F – Air Seal

G – Spring/Leaf Seal

H – Seal Mounting Flange

I – Seal Wear Surface

J – Discharge Breeching

K – Gas and Air Piping

L – Burners

M – Advancing Flights

N – Inlet Breeching

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

ROTARY CALCINER APPLICATIONS & MATERIALS

- Activated Carbon

- Alumina

- Biochar

- Catalyst Preparation & Activation

- Charcoal Production & Activation

- Electronic Waste

- Glass Materials

- Kaolin

- Petroleum Coke

- Phosphate Ore

- Pigments

- Plastics Processing

- Precious Metals

- Proppants

- Reduction Roasting

- Silica

- Specialty Chemicals

- Technical Ceramics

- Thermal Desorption of Organic Impurities or Hazardous Wastes

- Tire Pyrolysis

- Waste Lime Sludge

RESOURCES

PROJECT PROFILES

ROTARY CAlciner ARTICLES

The Role of the Calciner in Producing Soda Ash

Soda ash, or sodium carbonate (Na2CO3), is a versatile alkali material, critical in the production of a litany of products and …

Alternatives to Spent Catalyst Disposal

Catalysts continue to play a growing role in modern industry, carrying out an array of processes that otherwise might not be …