How Calcination Works

Calcination (also commonly referred to as calcining) is a thermal treatment used to cause chemical separation.

Processes Induced through Calcination

Calcination often uses heat, sometimes in the absence of oxygen, to induce one or more of the following things:

- Phase Transition/Change

- Removal of a Volatile Fraction

- Decomposition

- Removal of Crystalline Water

Commonly Calcined Materials

Rotary kilns are extremely flexible thermal processing devices, and are capable of processing a wide variety of materials. Some of the materials commonly calcined in a rotary kiln include:

- Technical Ceramics

- Kaolin Clay

- Refractories

- Alumina

- Spodumene Ore

*Note: The term “calcination” is often loosely used to refer to thermal treatment techniques that may or may not meet the technical definition.

Equipment Used

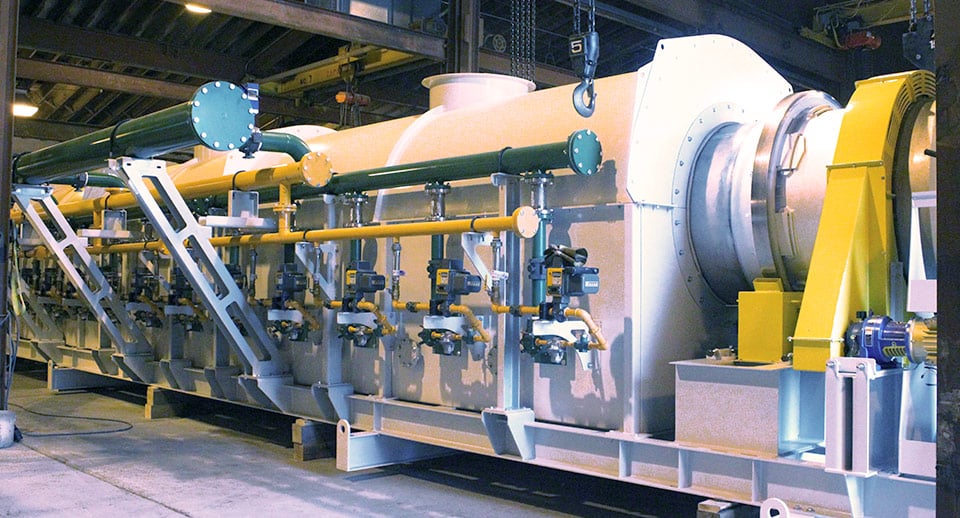

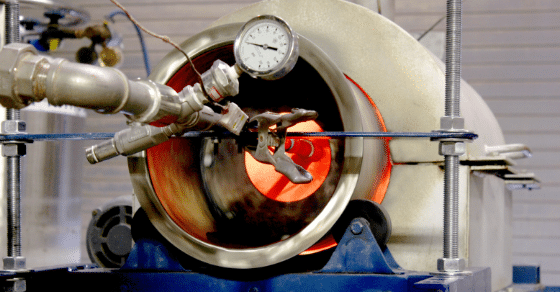

Rotary kilns are used to carry out the calcination process. Depending on the process goals and the material to be processed, the kiln may be of the direct-fired, or indirect-fired type.It is also common to follow the calcination process with a rotary cooler. This efficiently cools the material after it has been calcined, so it can move on to transportation or storage.

RESOURCES

PROJECT PROFILES

Calcination ARTICLES

Rotary Kilns: Processes Defined

A rotary kiln is a thermal processing tool used in a variety of applications. It consists of a rotating drum with …

From Batch Rotary Kiln Testing to Detailed Kiln Design

Since 1951, FEECO International has built a reputation as the leader in rotary kiln design and manufacturing. Part of our success …