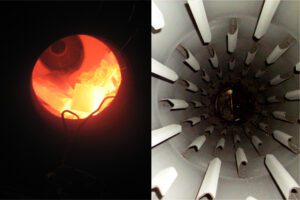

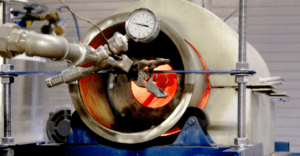

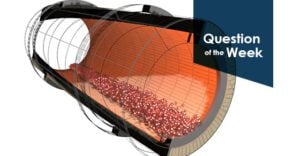

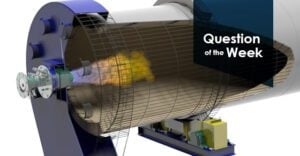

Rotary Kilns: Processes Defined

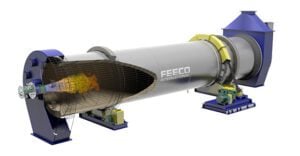

A rotary kiln is a thermal processing tool used in a variety of applications. It consists of a rotating drum with high temperature products of combustion flowing through or around it, creating a precisely controlled environment for material property change. Due to the substantially high …