Rotary drum tires, or riding rings, are one of the primary support components of a rotary drum, resting on trunnion wheels and allowing rotation of the unit on its base.

As technology has advanced, the approach to mounting drum tires has evolved, with each change in design improving on the last.

Today, the floating tire mounting style is generally considered the best available technology. While some older assemblies are still in use, the floating tire design has become standard in the industry for its superior performance.

About the Rotary Drum Floating Tire Design

The floating tire design is an improvement on previous tire mounting styles. Historically designs have included variations on:

- The Wedged Tire Mount Assembly in which rectangular wedges are pinned between the shell and tire.

- The Filler Bar Tire Mount Assembly in which fitted and arched plates are fixed to the drum shell and tire. (Both filler bar and wedged mount techniques employ “keeper blocks” (also known as retaining/retainer blocks) on the sides of the wedges or filler bars to prevent migration of the tire forwards or backwards.)

- The Direct Mount Assembly in which the tire is essentially shrink wrapped directly onto the drum shell.

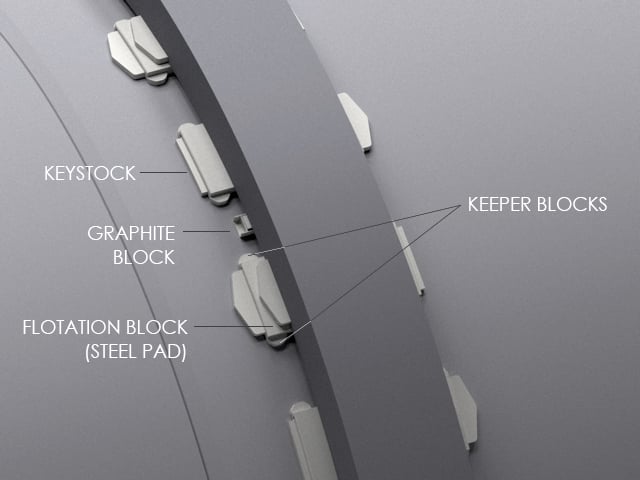

The floating tire design consists of formed flotation blocks (steel pads) on which the tire rides. Neither the tire nor the pads are fixed in place, but rather are held in place by keeper blocks. The tire is allowed to travel or free-float over the pads, which are made from a softer metal to promote wear on the pads instead of the tire. A graphite block mounted between pads provides a layer of lubrication to the tire as it passes over the block.

The image above illustrates the floating tire mount design, with keeper blocks keeping steel pads and the tire in place.

What’s Important in a Rotary Drum Tire-Mounting Assembly

Rotary drum tires play an integral role in maintaining the mechanical stability of a rotary drum. Tire-mounting style may seem inconsequential, but in fact has a significant impact on the overall longevity of both the tire and the rotary drum shell.

Decades of successes and failures with various designs have illustrated that there are three key criteria a tire-mounting assembly must meet:

Accommodate Thermal Expansion (for Hot Rotary Drums)

Rotary drums enduring temperature changes, including rotary kilns, dryers, coolers, and even some granulators, naturally expand and contract in response to the thermal cycling that occurs during start-up, shutdown, and production. This thermal expansion must be accounted for in the tire mounting assembly, or could otherwise result in severe damage to the drum shell, tire, or refractory.

Provide Support to the Drum Shell (and Refractory)

The tire must also provide adequate support to the drum shell and refractory (when applicable). A well-mounted tire should support the drum so that it runs true and concentric, allowing minimal ovality flex during rotation.

Allow for Maintenance

A key member of the support structure of a rotary drum, tires are made of seamless forged high-carbon steel, making them costly and time-intensive to replace. As a result, maintaining rotary drum tires is preferable to allowing wear.

The tire mounting style contributes significantly to the long-term condition of the tire. Through normal wear and tear, the mounting components can become worn and unbalanced, requiring routine adjustment to maintain optimal structural integrity and prevent the drum from becoming loose and wobbling (wobbling prevents the tire from tracking straight, creating a constantly changing state of misalignment).

Additionally, because the tire diameter is larger than that of the shell, the tire gradually migrates around the drum shell (this migration is known as creep).

Because of this, the mounting system should be designed to allow for adjustments when wear and/or creep becomes excessive. Further, these adjustments should be made as simple as possible, to lower barriers to upkeep.

Benefits of the Floating Tire Approach

The floating tire mount assembly significantly outperforms previous designs, offering several benefits:

Prevents Drum Shell Distortion

The most critical advantage to the floating tire mounting style is that it prevents shell distortion by allowing for the thermal expansion and contraction experienced by rotary drums that are subject to thermal cycling.

In hot applications, such as rotary drum dryers, the potential for distortion is managed with a “cold gap,” or a space between the drum shell and interior diameter of the tire. If the gap were too large, the drum could be allowed to flex too much, resulting in distortion and potential cracking of the shell or refractory; if the gap were not large enough, the drum may be too constrained, causing it to expand around the tires, again putting additional stress on the both the shell and refractory and potentially distorting the shell.

In contrast, the wedge tire mount style is largely intolerant of thermal cycling, experiencing significant wear as a result. The rigidity of the unmoving wedges and tires during cycling causes pins and welds to crack, requiring the tire mounting to be replaced.

The direct mount approach is even more restrictive on the drum shell when it comes to thermal expansion. Because the tire is fitted to the exact diameter of the drum, any thermal expansion will cause the drum shell to expand around the tire and over time, promote permanent shell distortion. Similarly, this design also does not allow for the natural flex that occurs when a drum rotates on a base. As a result, the use of the direct mount assembly in hot drums is not recommended, as it often results in cracked shells, tires, and collapsed refractory.

Maintenance Friendly

The nature of the floating tire design significantly improves ease of maintenance and accessibility, reducing the barriers to properly maintaining the tire.

With a wedged or filler bar tire mount, adjusting the tire is a complex process that takes several days and requires more labor and additional tools, and sometimes specialized welding techniques. In contrast, adjustment for optimal positioning with a floating tire mount design is typically carried out in a day, requiring significantly less labor and tools.

Direct-mount tires have proven to be especially problematic for maintenance, as they do not allow for any type of adjustment (they are also much more difficult to install). Additionally, because tires are fitted to the exact diameter of the drum shell, they do not come in standard sizes and must be custom made for each replacement.

Beneficial to Hot and Cold Drums

Another benefit to the floating tire design is that because it can accommodate thermal expansion, it offers benefits to both hot and cold drums.

The benefit of the floating tire mount on a hot drum is obvious, but lesser known are the benefits of using it on a cold drum. All drums – hot or cold – experience some level of flex (ovality) during rotation. Flex occurs on each rotation and in the case of the wedge mount style, causes welds and pins to fatigue and eventually fail. By utilizing the floating tire approach, these components are eliminated.

Reduced Operating Stress

The floating tire mount also generally reduces the physical stress placed on the drum and its many support components; by free-floating, the drum shell and tire are not restricted in any way, unlike with other styles where the components are subject to significant mechanical stress as a result of their fixed positions. Reduced operating stress on components also helps to promote a longer drive life, as mechanical stress is not putting a strain on the motor.

Conclusion

The floating tire mounting assembly is a significantly improved design over past mounting styles, offering a more maintenance-friendly approach that reduces stress and potential damage to both the rotary drum tire and shell, as well as other components. Existing drums are easily retrofitted with the floating tire mount with the help of an expert.

FEECO engineers and manufactures the most advanced rotary drums in the industry. Our Customer Service Team supports all FEECO and non-FEECO rotary drums with audits and inspections, repairs, retrofits, and more – tire replacement and mounting included. For more information on our service capabilities or rotary drums, contact us today!