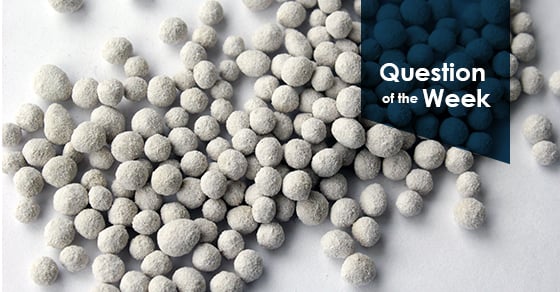

Non-pressure agglomeration, also known as tumble growth agglomeration, is a process which uses a tumbling motion and binding agent to grow material fines or powders into a spherical pellet form.

Non-pressure agglomeration methods include:

- Pelletizing (rotary drum or disc pelletizer): a process where material fines are rolled into uniform pellets with the assistance of a binding agent.

- Micro-pelletizing (pin mixer): a process where material fines are mixed with a binding agent to form small agglomerates, around 20-60 mesh, or to prepare the material for pelletizing.

- Conditioning: the mixing of material fines with a binding agent to reduce dust, and transform the material into a more easily handled and usable product.

Moisture must be either be present in the feed material or added during the non-pressure agglomeration process. As a result, the agglomerates are relatively soft (green, uncured) and typically require a secondary process step to dry, cure, or fire the agglomerate and provide the necessary product strength.

Various factors such as binder properties, industry standards, raw material characteristics, and equipment capabilities must be considered when determining which non-pressure agglomeration method should be used.

To learn more, download our agglomeration handbook, or contact a FEECO expert today!