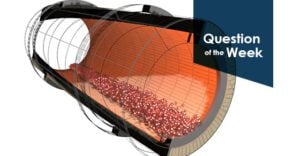

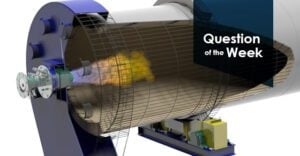

Question of the Week: What is Rotary Kiln Refractory?

Refractory is specific to direct-fired rotary kilns, insulating and protecting the shell of the drum from high internal temperatures; they also function to maintain heat retention. Many types of refractory exist, with the most common options being brick or castable. Brick is typically used for …