While demand for frac sand is nowhere near where it was during the boom seen over a decade ago, the industry is seeing somewhat of a resurgence, putting rotary dryer services in high demand.

In the 2010s, producers were looking to get their new plants up and running as quickly as possible, resulting in a deluge of new equipment orders, particularly rotary dryers. Now, however, that equipment is more than a decade old and starting to experience wear. As a result, many plant managers are looking to ensure their dryers are not only mechanically sound, but also ready to meet a potential increase in demand

What follows are some essential considerations for getting aging frac sand dryers back into shape.

Frac Sand Dryer Maintenance Considerations

Inspections & Audits

Operators and maintenance personnel should regularly be inspecting the dryer and addressing any issues that arise. If the equipment has not been thoroughly evaluated in some time, it is a good idea to have the original equipment manufacturer (OEM) or other qualified service professional perform an equipment audit on the unit to assess its mechanical condition.

This type of inspection provides a more in-depth evaluation of the equipment. Depending on the provider, the unit will likely be inspected inside and out and any items requiring attention noted. This type of evaluation also provides valuable benchmarking data for maintenance planning in the future.

Dryer Alignment

One of the most common procedures aging dryers require is an alignment. After years of operation, rotary dryers may have fallen out of alignment, particularly if underlying mechanical issues are present.

Wear on tires, trunnions, or thrust rollers, as well as gears, may indicate the presence of misalignment. Auditory abnormalities may also indicate an issue.

Using a laser tracking system, realignment can be conducted by a service professional quickly and with precision. An alignment is also strongly recommended after any major components (tiers or trunnion wheels) have been replaced or repaired.

Dryer Training (Float)

While alignment focuses on properly positioning trunnion wheels, training is centered on positioning the drum adequately between thrust rollers. This measurement is commonly referred to as “float” because ideally, the drum will float evenly between thrust rollers without the tires riding too hard on the uphill or downhill thrust roller.

Proper float is achieved through training, in which trunnion bearings are adjusted or “skewed” in very small increments to impact the direction and longitudinal thrust of the drum.

Since a rotary dryer operates on a slope, the float is constantly moving away from optimal conditions, requiring regular training to bring it back into proper position. Unfortunately, maintaining proper float is often overlooked, resulting in damage to tires, trunnions, thrust rollers and more.

As such, settings in which drum float has been neglected will not only require the drum to be trained, but may also require other repairs as well.

Tire & Trunnion Condition

Tire and trunnion lifespan can vary significantly depending on the operating and maintenance conditions, so many in the frac sand industry are likely still in good shape. When trunnions have been improperly skewed, damage can occur, significantly reducing their lifespan.

As such, plant managers should have an expert assess the condition of tires and trunnions to ensure they will remain reliable.

Grinding Worn Tires & Trunnions

Surface wear on tires and trunnions can often be addressed through grinding.

Timing marks, pitting, spalling, and other types of visible wear on tires and trunnions put undue stress on the drum’s mechanical components and can also cause (or result from) misalignment. Any wear on tires or trunnions should be addressed as quickly as possible to prevent further damage.

Tire and trunnion grinding is a reconditioning process in which the worn component(s) is ground down, or resurfaced, revealing the like-new surface beneath the wear. FEECO strongly recommends this process be followed by an alignment; if the root cause of wear is misalignment and the alignment has not been corrected, wear will immediately resume on the newly ground components.

Tire grinding in progress

Severe damage or excessive wear, such as cracks or gouges on tires or trunnions, cannot be remediated with grinding and will require replacement.

Gear and Pinion Replacement

At this age, the girth (ring) gear should still be in good shape; a quality gear can last upwards of 25 years. It’s important to note, however, that if the gear has not received proper lubrication and maintenance during its time in operation, it could be experiencing wear. Early onset wear may be addressed with simple adjustments, but in most cases, replacement is recommended.

Girth and pinion gears should be inspected to assess their condition. Wear on tires and trunnions, vibration around the drive assembly, or a “growling” noise may indicate an issue. The gear mesh (where the pinion and girth gear come together) may also provide evidence of an issue.

Upgrade the Burner

Burner technology has continued to evolve over the past decade, resulting in burners that are more efficient than ever. As such, upgrading the burner to a newer model can provide a welcome savings in fuel and energy, helping the dryer to run more efficiently.

Rotary Drum Shell Issues

Drum shell issues are not uncommon with frac sand dryers, particularly when working with light-duty equipment that was not built to withstand the specific challenges associated with drying frac sand.

Not surprisingly, abrasion of the shell (and other components in regular contact with the sand) is a primary concern. For this reason, the shell, along with inlet feed area and dryer internals (flights), should be inspected for wear, with any worn items replaced as needed.

Thin spots in the shell may not be visually apparent, but can be identified by measuring the temperature of the drum shell along its length as it rotates. A spike in temperature may indicate the need for repair, or depending on the severity, shell replacement.

If the drum was operated improperly at any time, warping or deflection in the shell may also be present. Because this affects the entire shell structure, replacement is typically the only option when this occurs. Warp or deflection are often indicated by problems where the drum meets the breechings.

Replacement rotary dryer shell

Seal Maintenance

Seals can wear over time, allowing air ingress into the dryer and ultimately reducing process efficiency. Worn seals should be repaired and/or replaced as needed.

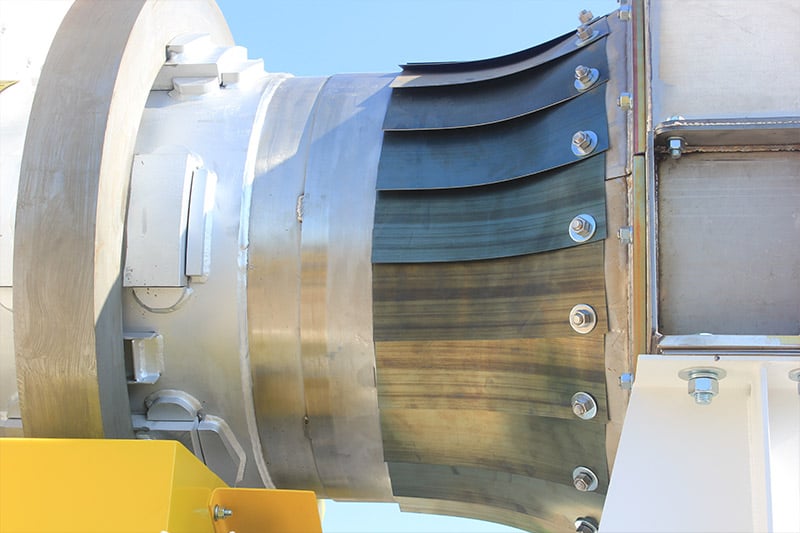

Leaf seal on a rotary dryer

Inlet & Discharge Breechings

The inlet and discharge breechings can also become worn over time, especially given frac sand’s abrasive nature. Depending on the severity of wear, breechings may require repair or replacement. Abrasion-resistant (AR) liners may also be implemented for added protection.

Spare Parts for Frac Sand Dryers

FEECO also recommends keeping an inventory of wear-critical and other spare parts in order to minimize potential downtime in the event of a failure.

Wear-Critical Rotary Dryer Parts to Keep On-Hand:

Wear-critical parts are those that the dryer cannot (or should not) run without, meaning that in the event of a failure, the entire operation is held at a standstill until the component can be replaced. For rotary dryers, the following wear-critical parts should be kept on-hand to avoid excessive downtime:

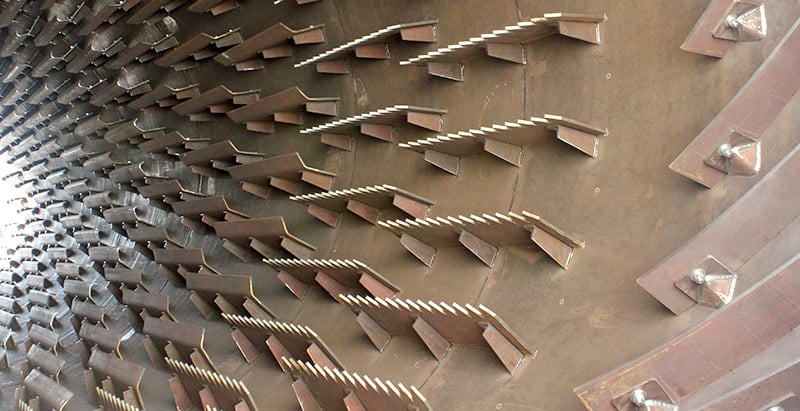

- Flights

- Trunnion wheels and bearings

- Replacement thrust roller assemblies

- Replacement pinion assemblies

- Graphite Blocks

- Replacement leaf seals and leaf seal plates

Flights in a frac sand dryer

A Note on Preventive Maintenance

FEECO recommends producers work preventively to address any issues they are experiencing with their dryers or its components, as this is significantly less costly than addressing the issue at the point of failure, particularly when that failure occurs unexpectedly.

A preventive maintenance program, including annual inspections by the OEM, is essential to upholding process efficiency and minimizing unnecessary downtime and maintenance costs, while maximizing dryer service life.

Conclusion

As aging equipment begins to degrade and the frac sand industry experiences a bump in demand, plant managers must consider the maintenance needs of their equipment in order to uphold production and maintain equipment integrity. Plant managers should pay particular attention to dryer alignment, condition of tires and trunnions, potential shell issues, and any worn components.

FEECO recommends a thorough equipment audit to assess the mechanical condition of the dryer and address any issues preventively, instead of being caught off guard by a sudden failure. The FEECO Customer Service Team can conduct any and all repairs mentioned here, including audits and the provision of spare parts. For more information on our frac sand dryer services, contact us today!