Rotary drums are central to many industrial processes, serving to dry, cool, agglomerate, heat, and even coat bulk solids.

While in some cases production can be redirected to another drum, or simply taken offline when a mechanical failure occurs, in most cases, an out-of-commission rotary drum holds the entire plant hostage.

For this reason, and as part of an effective preventative maintenance program, FEECO recommends keeping a variety of spare parts on-hand to minimize downtime and facilitate a quick change out.

Wear-Critical Rotary Drum Parts

The following parts are considered “wear-critical,” meaning that the drum either cannot or should not be operated without them. Spares of these parts should always be kept on hand to avoid excessive downtime, particularly when plants are located in a remote setting.

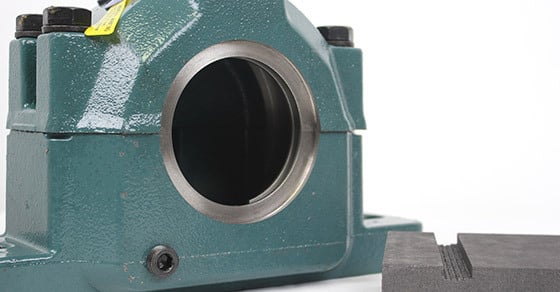

Trunnion Wheel Bearings

Trunnion bearings facilitate rotation of the trunnion wheel. Though trunnion bearings do not fail often, when they do, the rotary drum cannot remain in operation, as the trunnion could become locked up. If the rotary drum were allowed to continue operating when this happens, the tire could grind against the trunnion, causing significant damage.

Trunnion bearings typically have a lead time anywhere from 4 to 30 weeks, depending on the size, so having a replacement on hand is essential to avoiding weeks of downtime and lost production.

FEECO typically recommends always keeping a minimum of two trunnion bearings on site in the event of a major failure. Since the bearings on a given trunnion experience the same wear conditions, when one fails, the other is usually not far behind.

Thrust roller assembly

Thrust Roller Assemblies

In the event that a thrust roller fails, there is nothing to stop the drum from drifting in the direction the thrust roller was previously preventing, creating a dangerous and potentially catastrophic situation if the drum were to remain in operation. This is especially likely if the thrust roller failed as a result of the drum pushing too hard against it.

Oftentimes, it is helpful to keep an entire thrust roller assembly on hand; in the event of a failure, maintenance personnel can remove the damaged assembly, replace it with the new one, and repair the old one for use as a spare in the future.

Lead time for the thrust roller and/or bearing generally ranges from 2 to 8 weeks; if the plate weldment is included, the timeline falls around 6-8 weeks, again making a ready replacement critical to preventing further downtime.

Thrust Roller Bearings

Just as with the failure of a thrust roller assembly, the failure of a thrust roller bearing also requires the drum to remain shut down to prevent the drum from drifting excessively.

Thrust roller bearings alone typically have a lead time of 1-2 weeks.

Graphite block for lubricating tires and trunnion wheels

Graphite Blocks

Graphite blocks are used to provide lubrication to tires and trunnions. It might be tempting to continue operation temporarily without lubrication, but this can result in significant damage to both the trunnion and tire.

Lead time on graphite blocks generally ranges from 2-4 weeks.

Additional Rotary Drum Components to Stock

Keeping the above wear-critical parts in stock should be the top priority, but it can be helpful to keep a few other parts on hand as well.

Bolt-in rotary dryer flights

Flights

For rotary dryers and coolers, flights are not essential to operation, but they do contribute to heat transfer and ultimately drying or cooling efficiency. Having extra flights on hand is helpful to replace worn flights as needed in order to maintain operational efficiency.

Seal Leaves

For the same reasons, FEECO also recommends keeping a few extra seal leaves on hand for dryers, coolers, and kilns, in the event that any become worn or damaged. A broken seal leave won’t leave an operation at a standstill, but it does impact process efficiency.

Drive Components

Drive components rarely fail and typically provide warning before they do, but they are still essential to the functioning of the drum. As such, consider stocking a motor, reducer, and couplings as an added precaution.

In Need of Spare Rotary Drum Parts?

The FEECO Customer Service Team is only a phone call away! Contact us today to discuss your spare parts needs, as well as our other rotary drum services, including inspections, process audits, equipment repairs, and more.