From developing a new product, to optimizing an existing process, the agglomeration testing conducted in the FEECO Innovation Center provides a pivotal link between question and answer for producers looking at particle agglomeration as a way to solve their material challenges.

The following information offers an overview of this testing and the many questions it can answer for producers working with bulk solids.

What is Agglomeration?

Agglomeration is a particle size enlargement technique used not only to solve a wide array of material problems, but also to improve product performance by engineering particle characteristics. With a number of potential benefits, agglomeration is used in a myriad of ways throughout nearly every industry working with bulk solids.

Numerous methods and approaches to agglomeration are available, with the Innovation Center focusing on wet granulation, also known as agitation agglomeration, pelletizing, or tumble-growth agglomeration.

The numerous types of equipment and approaches to agglomeration can mean the path to the end goal is not always clear. Paired with the unpredictability of how a given material will respond to agglomeration, testing becomes essential to determining not only if agglomeration is the right fit, but if so, what approach will achieve the desired results most efficiently.

What Can Be Tested

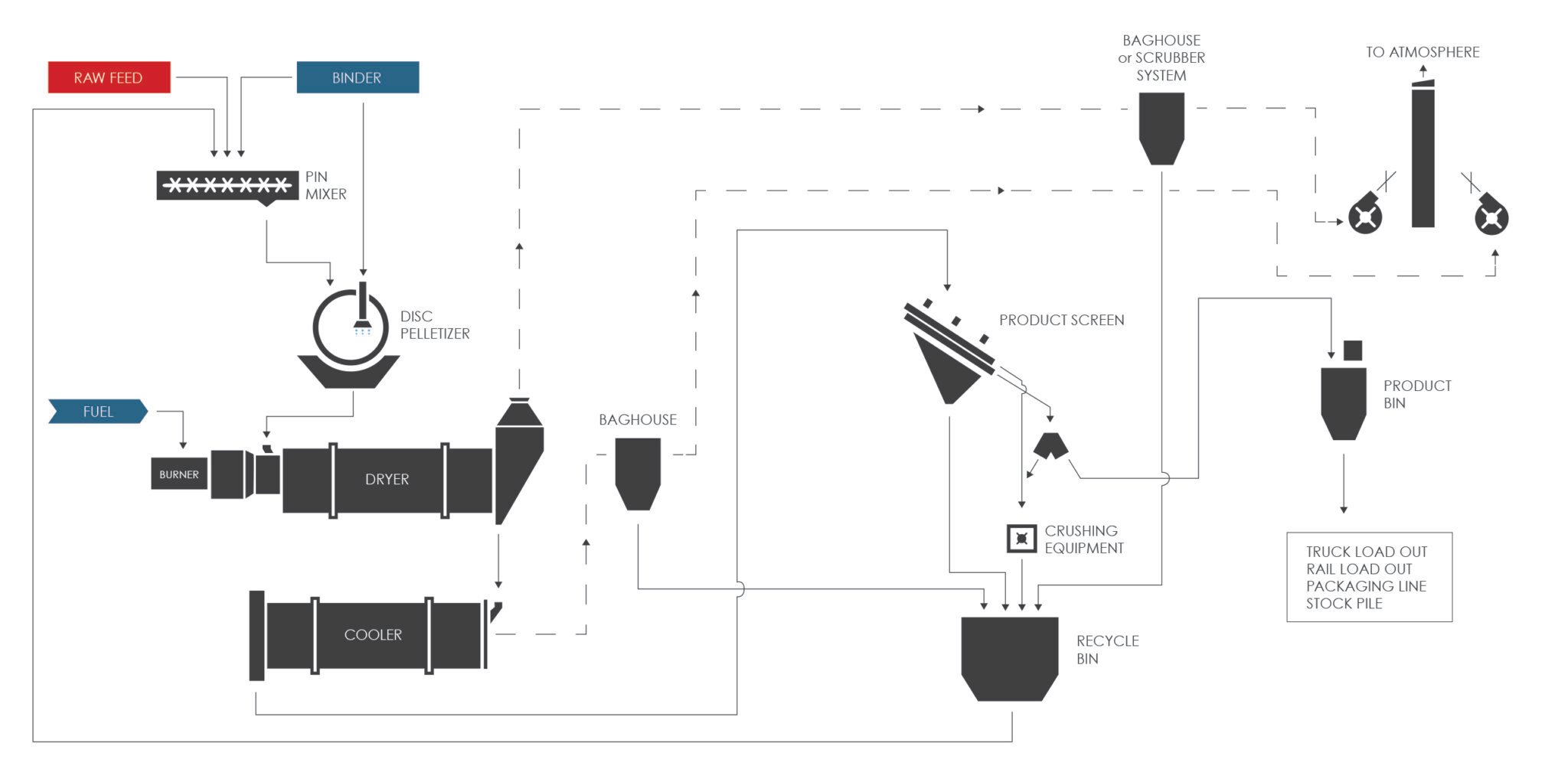

The Innovation Center is equipped to test various aspects of the agglomeration process, from batch testing on a single piece of equipment, to a continuous process loop incorporating agglomeration, drying, and a recycle circuit. The following methods and types of agglomeration equipment can be tested:

- Conditioning/De-dusting (Pugmill mixer, pin mixer, rotary drum)

- Micro pelletizing (Pin mixer, disc pelletizer)

- Pelletizing/Granulation (Disc, drum)

- Mixing (Pugmill mixer, pin mixer, rotary drum)

- Coating (Rotary drum)

Testing typically starts at batch scale and if successful, progresses to continuous, pilot-scale testing. During this time, various process and equipment parameters can be adjusted to reach the desired result.

Several particle characteristics (e.g., size, bulk density, moisture content, etc.) can also be evaluated during and after testing to ensure the product meets specification.

Questions Agglomeration Testing Can Answer

1. Will my material agglomerate?

Agitation agglomeration can be used to treat a broad spectrum of materials, but it is not a fit for every material. All materials, and even the same type of material from different sources, will respond differently to agglomeration.

Some materials will readily agglomerate with little assistance, while others simply will not agglomerate, or may require substantial preconditioning to bring them to a point where agglomeration is possible.

Material before and after agglomeration during testing in the Innovation Center

Process experts in the Innovation Center use batch-scale tests conducted with small samples of material to assess the initial feasibility of agglomerating a specific material. These tests reveal whether or not the material is capable of agglomeration, and therefore, if the process merits further exploration.

2. Can agglomeration solve my material problem?

Agglomeration is regularly employed to address a range of material problems, some of the most common of which include:

- Flowability issues

- Handling challenges

- Particle segregation

- Application problems

- Inferior performance

- High transportation costs

- Significant dust and/or product loss due to dust

To uncover whether or not agglomeration could solve the issue at hand, process experts produce small samples of material that can be further assessed or used in field trials to establish their effectiveness.

Pelletized iron ore

3. What equipment configuration will be required to produce the results I’m looking for?

A variety of agglomeration equipment is available. Depending on the desired end product characteristics, as well as the raw material characteristics and specific process requirements, some types of equipment are likely to be a better fit than others. For example, when working with a feedstock of finely divided solids, a pin mixer is usually a better choice compared to a pugmill mixer, since the pin mixer is more self-contained.

Likewise, if size control and a highly refined product are the goals, a disc pelletizer is likely to offer a better option compared to a rotary drum agglomerator. Equipment is also frequently combined in different configurations to achieve the desired end product specifications. A common setup is the pin mixer and disc pelletizer combination, favored for its particle size control capabilities and the refined product it yields.

Typical agglomeration setup utilizing a pin mixer and disc pelletizer combination to achieve agglomeration

Determining the optimal equipment configuration can be challenging and is best carried out by an expert with an extensive background in agglomerating different kinds of materials and a solid understanding of the different methods of agglomeration.

Through systematic testing, paired with experience, process experts in the Innovation Center can reveal the best equipment configuration based on the specific process objectives.

4. What binder, if any, will work best for my material?

Binders, or binding agents, are used in non-pressure agglomeration processes to facilitate particle cohesion, maintain pellet integrity throughout processing, and reach the desired end product quality.

Binding agents are an industry of their own, with hundreds of options and variations available. While binder type is often narrowed down based on end product use, there are still many options to explore.

Testing can be used to evaluate which binder performs well, yields the desired product quality, and is economically feasible. Here again, experience is an asset. Binder formulation, temperature, concentration, feed rate, and other factors can also be assessed.

A process expert in the Innovation Center evaluates a binder in the agglomeration process on a disc pelletizer

5. Can my product be improved?

Agglomeration testing is frequently used to evaluate the potential improvement of a product, as well as whether or not that improvement is economically viable.

Testing may focus on the general enhancement of a material through agglomeration, or the improvement of an existing agglomerate product for better performance and handling.

Potash pellets on a sieve during a particle size distribution (PSD) evaluation

Since testing assesses the ability to reach different product parameters, various determinations can be made. Importantly, particle coating can also be tested, which gives producers an additional avenue to meet product formulation, appearance, and performance goals.

Coated and uncoated urea

6. How can I optimize my existing process?

There are two primary ways in which agglomeration testing can be used to optimize an existing process:

Improve upon the agglomeration process itself

Reaching the desired results in an agglomeration production setting relies on several factors working together. As such, when any one factor falls out of spec, problems may arise.

Testing can be used as a means of troubleshooting an agglomeration process that produces excess off-spec product, requires frequent shutdowns, is unable to reach rated capacity, or is simply underperforming.

Similarly, testing can be employed as a means of improving the process in other ways as well. This might include optimizing the drying portion of the process or assessing whether a preconditioning step could increase throughput and efficiency.

One of the key benefits to utilizing a testing facility like the Innovation Center is that it allows the problem or change in production conditions to be assessed systematically in a controlled environment, without impacting the live production facility.

Improve downstream processing by using agglomeration as an intermediary step

Agglomeration is not just a means of producing end products; it can also be used as an intermediary step to improve downstream processing conditions. This might involve controlling the density, meltability, porosity, or other particle parameters.

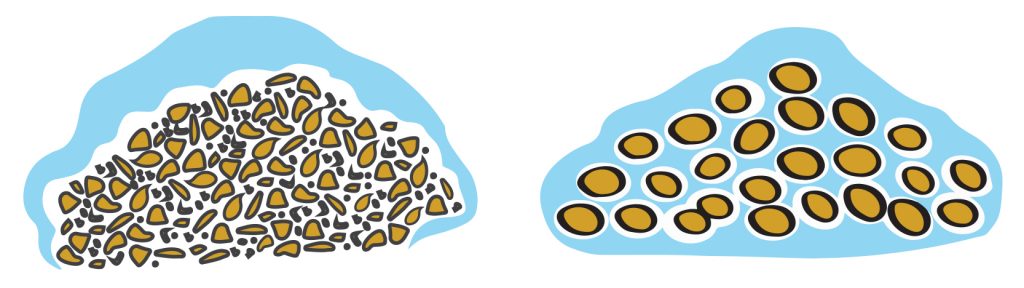

This is commonly seen in settings where bed permeability (the ability of a liquid or gas to pass through a material bed) is critical, as agglomeration of fines improves bed permeability, as shown in the image below. A common example of this can be found in the mining industry where ore fines are agglomerated prior to heap leaching to improve recovery of the target mineral.

Bed permeability before (left) and after (right) agglomeration of fines

7. Can agglomeration reduce the amount of dust/product loss my material experiences?

The challenges associated with a dusty material represent the most common reasons for which producers choose to agglomerate material.

Agglomeration significantly reduces, and in some cases eliminates dust, with some techniques providing better results than others.

Producers utilizing roll compaction, extrusion, or other pressure-agglomeration techniques may also choose to evaluate agitation agglomeration as an alternative to their existing process as a way to mitigate dust issues; pellets produced via pressure-agglomeration techniques tend to have friable, jagged edges that rub together and break down into dust, a phenomenon known as attrition.

The Innovation Center routinely performs attrition tests to determine the amount of degradation likely to occur with a given product. Various techniques can be tested to control the amount of attrition and minimize dust.

Carbon black is often pelletized to eliminate dust

8. Is it possible to make my product on a continuous, commercial-scale basis?

Testing may also be used to assess the viability of a process or product as a continuous, commercial-scale operation.

In this case, continuous tests are conducted in order to obtain the factors necessary for scaling up the process. At the same time, process engineers watch for red flags and potential issues to work around when implementing the process at commercial scale.

A continuous testing setup utilizing a pin mixer (not visible), disc pelletizer, and rotary dryer in the Innovation Center

Conclusion

Agglomeration is an incredibly powerful tool in controlling particle characteristics and solving material problems when working with bulk solids, but its flexibility and diversity can make evaluating agglomeration and developing the optimal process around it challenging.

Testing in a facility such as the FEECO Innovation Center can answer all of the questions listed here and more. With comprehensive testing capabilities, and an unmatched expertise in agglomeration, testing in the Innovation Center is the most efficient way to evaluate a new or existing agglomeration process. To learn how we can answer your agglomeration questions, contact us today!