Increasing Efficiency with Process Training for Pelletizing

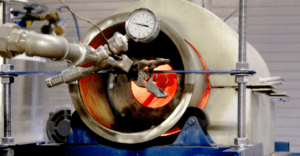

Disc pelletizer training is a commonly overlooked, but essential aspect to a successful pelletizing operation. Pelletizing material on a disc pelletizer is considered a blend of both art and science; a number of variables must be balanced to maintain consistent product throughput and produce an …