The rotary dryer is the industrial dryer of choice for everything from minerals and ores to fertilizers and specialty chemicals. One decision buyers are often faced with in selecting a rotary dryer for a given application, particularly when looking to dry high-moisture materials such as compost or biosolids, is whether to go with a single-pass or triple-pass rotary dryer.

While both designs offer distinct benefits, those looking for a drying solution that will minimize downtime and remain reliable in the long term should opt for the single-pass rotary dryer. Here’s why.

What’s the Difference Between a Single Pass and a Triple Pass Rotary Dryer?

Before we get into the advantages of single pass rotary dryers, let’s first take a look at how these two dryer types differ in operation and construction.

Single Pass Rotary Dryers

Single pass rotary dryers consist of a single, heavy-duty drum through which material and products of combustion are passed while the drum, set on a slight slope to allow gravity to assist in moving material through, rotates.

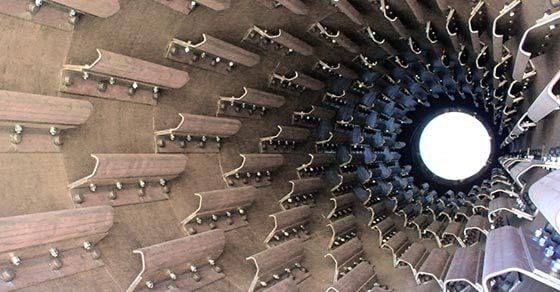

Flights affixed to the drum’s interior pick up material and cascade it through the gas stream as the drum rotates to maximize heat transfer between the material and products of combustion.

Single pass rotary dryers are used for a wide range of materials throughout many industries, offering a high level of opportunity to customize them to the specific challenges of the material at hand.

Triple Pass Rotary Dryers

Triple pass rotary dryers consist of three lighter-duty drums of differing diameters nested inside each other. The drum is not set on a slope, but rather relies on pneumatic conveying to carry material through the unit.

Material is fed into the innermost drum, and is pushed out the end of that drum where it falls into the middle drum. Similarly, the material works its way through this drum, out the end, and into the remaining, outermost drum shell, where it moves through and is discharged at the end.

Triple pass dryers are generally employed for high-moisture applications where longevity is less of a concern. As such, they are often used in drying various types of biomass.

Choosing Between a Single Pass and Triple Pass Rotary Dryer

The main advantage provided by the triple pass design is that it allows the drum length to be reduced for a smaller footprint. This is because the triple pass dryer achieves a longer retention time through the multiple pass system as opposed to additional length. While this is one area where single pass dryers concede to triple pass dryers, the benefits typically stop there.

Single pass dryers offer several advantages over the triple pass design:

More Reliable and Longer Service Life

One of the primary reasons for selecting a single pass dryer over a triple pass dryer is the increased longevity and reliability of the design.

Triple pass dryers are a much lighter-duty solution compared to single pass dryers, relying on less robust drum shells and tire arrangements. This offers an initial savings in capital cost, but significantly reduces the service life of the dryer. This lighter-duty design also means that triple pass dryers are much more prone to experiencing issues in high-demand settings.

In contrast, because single pass dryers rely on a single shell, that shell is designed to be much more robust and durable. Single pass rotary dryers have a well-deserved reputation of lasting for decades when properly maintained, though this does also depend on selecting a reputable rotary dryer manufacturer.

Less Prone to Clogging

In addition to fewer mechanical and structural issues, single pass rotary dryers are also less prone to clogging than triple pass dryers; because material is initially fed into the smallest inner drum with the triple pass design, there is less space for the material to fall as it moves through the drum, even with the help of lifting flights. This often results in material clumping up and subsequently clogging the dryer.

Similarly, triple pass dryers are generally not recommended for materials with a larger particle size (greater than one inch), as this is also likely to result in clogging issues.

The larger diameter of the single pass dryer, combined with the lifting flights, gives material adequate space to fall through the air stream, a motion that can also help to break up any potential clumps. As a result, single pass dryers are less susceptible to clogging issues.

Requires Less Energy

Because triple pass dryers pneumatically convey material through the drum, they require a high air velocity. This leads to the need for a larger induced draft (ID) fan and exhaust handling system, ultimately increasing energy requirements.

Less Off-Gas Treatment

As a result of the higher volume of air used by triple pass dryers, they also require a larger exhaust gas treatment/air pollution control system. Single pass dryers still require an off-gas treatment system, but it can be much smaller due to the reduced air volume utilized.

Conclusion

Single and triple pass rotary dryers are commonly compared in selecting a dryer for high-moisture applications. While the triple pass dryer costs less and offers a smaller footprint, the reduced service life and reliability are substantially reduced and in most cases, not worth the sacrifice. Single pass rotary dryers are robust, offering a significantly longer service life and more reliability. Other benefits of the single pass design include less potential for clogging, lower energy costs, and reduced off-gas treatment requirements.

FEECO rotary dryers provide every industry from mining and minerals to fertilizer and agriculture with the most reliable drying solution. Our single pass dryers are custom built for optimal processing efficiency and long-term reliability. Plus, they are backed by our extensive parts and service program. For more information on FEECO rotary dryers, contact us today!