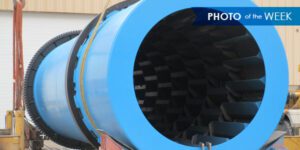

Photo of the Week: Rotary Dryer

This week’s photo shows welders installing flights in a rotary dryer. FEECO has a respected name in the thermal processing industry, supplying customers with not only rotary dryers and coolers, but with rotary calciners and kilns too. Flights are located on the drum’s interior and …