Pugmill Mixer FAQs

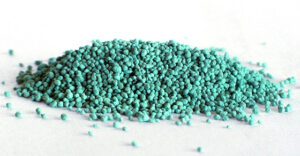

The pugmill mixer, also known as a pug mill or paddle mixer, is a type of horizontal industrial mixer used for processing bulk solid materials in conditioning, de-dusting, and granulation applications. This type of mixer is widely employed throughout various industries as a means of …