When considering the use of an industrial mixer, be it for pre-conditioning prior to a disc pelletizer, or for use as a stand-alone agglomeration unit, it is common to run into the question of which mixer will serve the process and material best: a pin mixer, or a pugmill mixer.

While both pieces of equipment are effective continuous industrial mixers, they each have distinct benefits and capabilities. Typically, the material itself, along with processing considerations, will help in determining which type of mixer will best fit the needs of the process and material. The following information outlines the basics on each mixer’s capabilities.

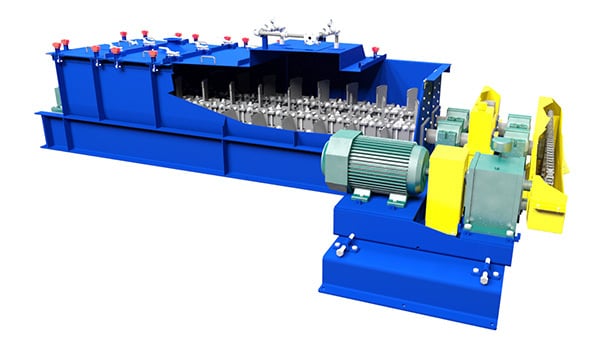

Pugmill Mixers

How It Works: Material undergoes tumbling, kneading, and medium-shear action, resulting in an intimate mixture of materials.

Typical Use: Mixing, conditioning, or agglomerating.

Processing with a Pugmill Mixer

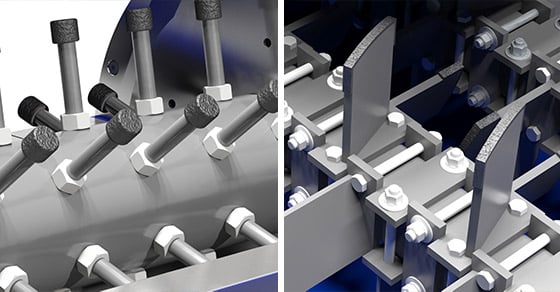

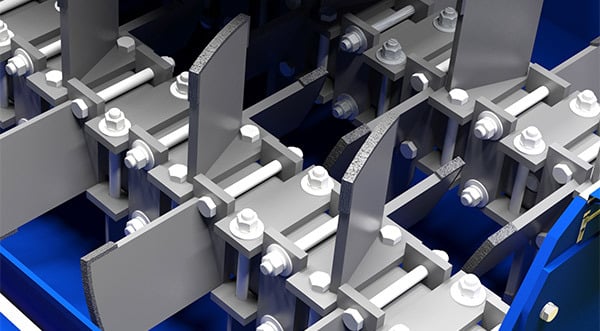

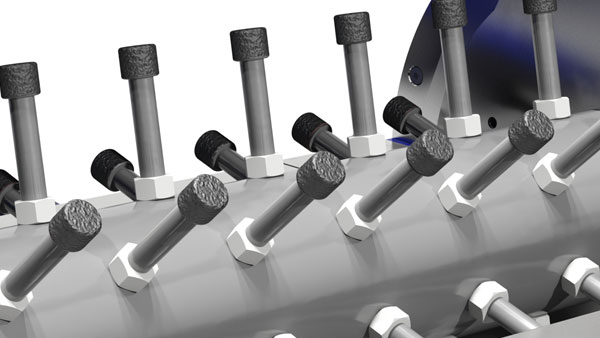

The pugmill mixer is composed of a U-shaped, horizontal trough. Inside the trough, a series of pitched paddles are mounted on dual counter-rotating shafts that run the length of the device. The paddles move material from the bottom of the trough, up the middle, and back down the sides, creating a kneading and folding effect that intimately mixes the material.

The pugmill mixer is widely used for conditioning material. In these instances, a liquid spray system is added to dispense a binder that assists in the conditioning process.

Pugmill Mixer Applications

The kneading motion of a pugmill mixer makes this type of industrial mixer best suited for heavy-duty materials and applications. Typical material applications include:

- Mixing: FGD scrubber sludge, fly ash and lime for SO2 neutralization, municipal sludge for composting facilities, and other processes combining moist and dry feed materials.

- Conditioning: Fly ash, cement or lime kiln dust, foundry dust, iron-oxide, friction material waste, lead fume, iron ore dust, and zinc oxide.

- Agglomeration: Granulation of a variety of materials: agricultural chemicals, fertilizers, pesticides, coke fines, chemical consumer products, carbon powders, cement kiln dust, flue dust from dust collectors, pigments, and dyes.

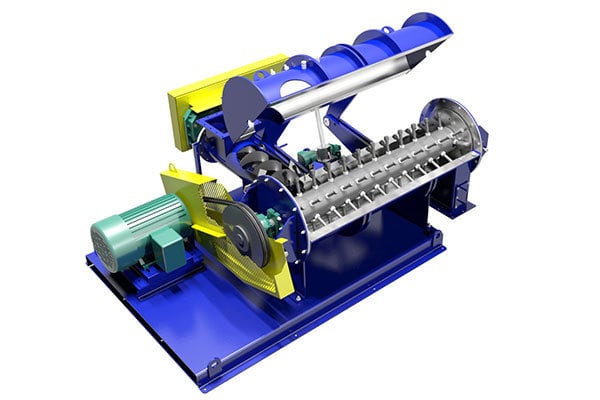

Pin Mixers

How It Works: Material undergoes an intense spinning action, resulting in densification.

Typical Use: Micro pelletizing, solids mixing, densification, de-dusting, pre-conditioning, conditioning, and granulation.

Processing with a Pin Mixer

The pin mixer is comprised of a stationary cylindrical shell that houses a high-velocity central rotor shaft. The rotor shaft extends the full length of the mixer, with numerous rods (or pins) that extend outward. A constant speed motor spins the rotor shaft at several hundred RPMs in order to impart agitation forces on the material. The motion and high rotational speeds produced by the pin mixer minimize air and reduce water volume between particles in the material. This results in densification many times that achieved with a disc pelletizer. A fluid binder material is added in order to aid in the agglomeration process.

Pin Mixer Applications

Pin mixers are ideal for processing fine materials such as powders. Typical pin mixer material applications include:

- Calcium chloride

- Carbon black

- Sodium aluminum chloride

- Mine fines (such as zinc sulfate)

- Coal dust

- Pigment

- Gypsum

- Limestone

- Other fine particle materials

Pin mixers work well as a stand-alone agglomeration unit, or as a pre-conditioner in a two-stage agglomeration process involving a disc pelletizer. Pin mixers are also ideal components in an automated system, offering precise quality control and accurate production rates.

Choosing Between a Pugmill Mixer and a Pin Mixer

Both mixer types provide a wide array of benefits and processing capabilities. When evaluating which industrial mixer will be most suitable, the material may help in making the selection. Processing system requirements and facility considerations are also used to determine the most fitting equipment solution. However, the best way to choose between the two is to evaluate the raw material and decide what type of outcome is preferred; the equipment’s capabilities will lead to choosing one device over the other. The most common considerations in making a decision between the two types of mixers are listed below.

Material Characteristics

Sticky and/or Abrasive Materials

A pugmill mixer tends to handle sticky and/or abrasive materials better than a pin mixer, because of its slower speed. Pin mixers would likely get “bogged down” when trying to process a sticky material, and would not stand up as well to a severely abrasive material, due to the high rotational speed.

Potential for Tramp Material

A pugmill mixer is also more forgiving than a pin mixer, an ideal characteristic when working with tougher materials, or where tramp material could possibly enter the mixer. While a stray rock or tramp bolt may cause a few pins to break off in a pin mixer, the pugmill mixer would likely not see any damage.

Particle Size Distribution

The same is true when working with large particle sizes. Large particles could lodge between the pin tips and the interior wall of the pin mixer. In a pugmill mixer, however, the clearance between the trough and paddles is greater, decreasing opportunity for material to become lodged. The pugmill mixer also typically has enough torque to dislodge particles as well, should any become stuck.

Densification

When looking to densify a material, the high-speed spinning action that occurs in a pin mixer can offer much better results. Pin mixers are also ideal in working with ultra-fine materials, such as pigments and dyes; the mixer’s ability to effectively micro pelletize a fine powder is tough to beat.

Throughput

The pugmill mixer offers a significantly higher throughput than a pin mixer, making it an attractive option for high-capacity operations.

Testing Industrial Mixer Capabilities

Although the choice between the pin mixer and pugmill mixer is often clear, in some cases there may be significant overlap, or there may be questions as to which mixer will best achieve the desired result. When this occurs, testing in the FEECO Innovation Center can offer additional answers.

Experts in the Innovation Center can test material in both mixer types under different process conditions and configurations to evaluate which mixer will best meet the requirements. The Innovation Center also offers a pilot plant for development testing, helping to establish and refine process variables, equipment configurations, and the requirements necessary to produce material on a continuous basis.

Conclusion

The choice between a pin mixer and a pugmill mixer is often dictated by the material itself, with pin mixers better serving fines and pugmill mixers better suited to more heavy-duty requirements. Both types are effective industrial mixers, with each offering their own advantages and disadvantages. Testing is sometimes necessary to evaluate both mixer types and determine the most fitting approach. For more information on FEECO industrial mixers or testing in the Innovation Center, contact us today!