Common Disc Pelletizer Issues (and How to Overcome Them)

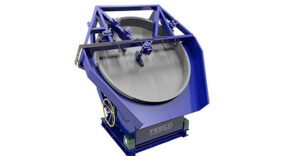

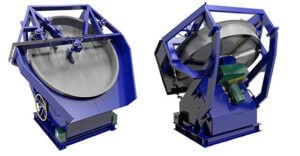

Disc pelletizers (pan granulators) are an invaluable tool in processing powders and fines into easily handled, dust-free agglomerates fit for use in any industry. One of the primary reasons for which this type of agitation agglomeration device is chosen, is for the high level of …