Catalyst size and shape play a crucial role in optimizing reaction efficiency. As the chemical industry pushes for more effective processes, spherical catalysts produced through pelletizing (wet granulation) have emerged as a solution with significant advantages in many settings.

This article examines the importance of spherical catalysts in industrial applications, their unique benefits, and how the pelletizing process allows precise control over their critical physical properties.

Why are Catalyst Size and Shape Important?

In addition to a heightened focus on efficiency, many in the fine chemicals industry have or are in the process of transitioning from batch to continuous operations, resulting in greater demand for more advanced catalysts suitable to these processes. One essential aspect of this is the switch from fine powders to larger particles, which are more amenable to continuous flow and avoid the clogging that can otherwise occur with powders.[1]

These trends have opened the door to increased exploration around particle engineering for catalysis.

The size and shape of a catalyst can have a significant influence on its catalytic activity and overall performance in reactors – surface area, flow dynamics, and other critical performance factors are heavily influenced by the physical parameters of these materials.

Catalyst size and shape are dependent on the type of reactor and application in which they will be employed.[2] The size and shape of the solid requires striking a balance between two critical aspects of effectiveness; the particles must be small enough that gasses can easily move through the material bed, but large enough that they won’t create blockages in the reactor and contribute to a drop in pressure.[3]

What are the Advantages of Spherical Catalysts and Catalyst Supports?

While many shapes are available on the market, spherical catalysts and supports continue to be explored for the numerous benefits they can offer. Further, their flexibility allows them to be employed in a range of different reactor types, making them applicable in a variety of settings.

Though they are not appropriate in all settings, in the right setting, spherical catalysts can offer several important advantages over extrudates and other shapes:

Minimal Pressure Drop

One of the most critical advantages producers using packed beds can leverage is the significant reduction in pressure drop within the reactor that spherical particles promote. This can lead to increased output without the need for major modifications to equipment.[4]

Enhanced Catalyst Dispersion

A spherical catalyst support allows for a homogeneous distribution of nanoparticles over the support, ultimately leading to better catalytic performance.[5]

Increased Catalyst Longevity

In addition to reducing pressure drop, the enhanced mechanical strength of spherical supports contributes to extended catalyst life in high-stress environments.[6]

Improved Handling

Spherical catalysts and substrates experience minimal dust, making them easier to handle and less likely to generate fines that could clog reactors.

More Uniform Flow

Spherical particles promote enhanced flow dynamics in packed bed reactors, thanks to their geometry. Large-pore catalysts on spherical supports in packed beds can help to minimize dead zones and improve reaction efficiency.[7]

This uniform flow also holds true in the post-forming calcination step; the rounded granules promote enhanced heat transfer in the material bed of the downstream rotary kiln, helping to maximize efficiency and minimize the energy costs associated with calcination.

Greater Available Surface Area

Similarly, the geometry of spherical particles creates void spaces in the packed bed which increase the surface area available for reaction, improving overall performance.[8]

Longer Catalyst Life

The uniform structure of spherical catalysts also prolongs catalytic activity and lengthens the time to deactivation. This reduction is also in part due to the even distribution of active sites across the support that a spherical shape allows, as mentioned earlier. This helps to minimize stress and hot spots which could lead to fouling or coke formation and ultimately deactivation.[9]

Lower Attrition

Spherical particles exhibit less attrition, because there are no jagged edges to rub together and break down into fines. While this is beneficial in all settings, it is especially important in riser reactors. These reactors employ a continuous transport of the catalyst material, requiring granules to be as smooth and as strong as possible, so as not to break down under constant movement.[2]

Improved Coating Capabilities

When used as a catalyst support that will require impregnation, spherical granules can promote a more uniform distribution of the catalytic solvent over the support material, particularly when carried out in a rotary drum.

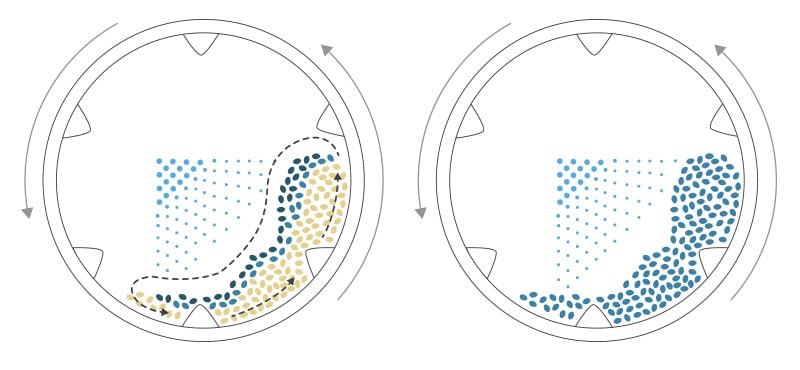

Similar to how they increase the surface area available to the reactor, spheres also provide more surface area for a liquid coating application. Further, when carried out in a coating drum, or “impregnator,” the rolling action of the granules improves distribution of the solvent throughout the material bed, as shown below.

What Applications Use Spherical Granules?

As a result of these benefits, spherical granules are widely employed in a myriad of ways across several industries, with common applications including:

- Hydrocracking

- Catalytic reforming

- Desulphurization

- Dehydrogenation

- Ammonia synthesis

- Methanol production

- Polymerization

These applications take advantage of the spherical shape for consistent performance, efficient catalytic activity, and ease of handling and packing in reactors.

Catalyst Formation

Catalysts and supports are generally produced using one of three agglomeration processes: pelleting, extrusion, and granulation [(pelletizing)], the choice between which centers around factors such as desired particle size, shape, density, and strength.[3] Both pelleting and extrusion use pressure to form shapes, while pelletizing (wet granulation) is considered a non-pressure technique. Note: There are many names for these processes and they are often used interchangeably.

The characteristics of the raw material also come into play, as not all materials respond favorably to all methods of agglomeration.

Pelletizing Catalysts: The Disc Pelletizer-Pin Mixer Approach

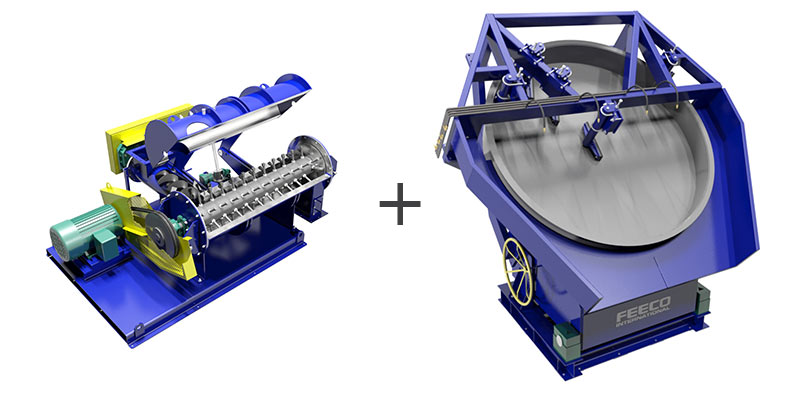

Spherical catalysts can be produced through a few different techniques. Here, we’ll focus on wet granulation or pelletizing using a disc pelletizer-pin mixer combination.

While both pin mixers and disc pelletizers can be used on their own to produce rounded granules, the combination of the two types of equipment can offer an ideal combination for catalyst production.

3D Pin Mixer (left) and Disc Pelletizer (right)

Utilized throughout various industries for the many benefits it can offer, this pelletizing configuration gives catalyst producers the ability to produce highly refined spheres with a narrow size distribution. Further, the pin mixer is able to achieve density through motion, allowing for a reduction in the use of binder to achieve the desired mechanical strength (if a lower density is desirable, a disc pelletizer may be used without the preceding mixer).

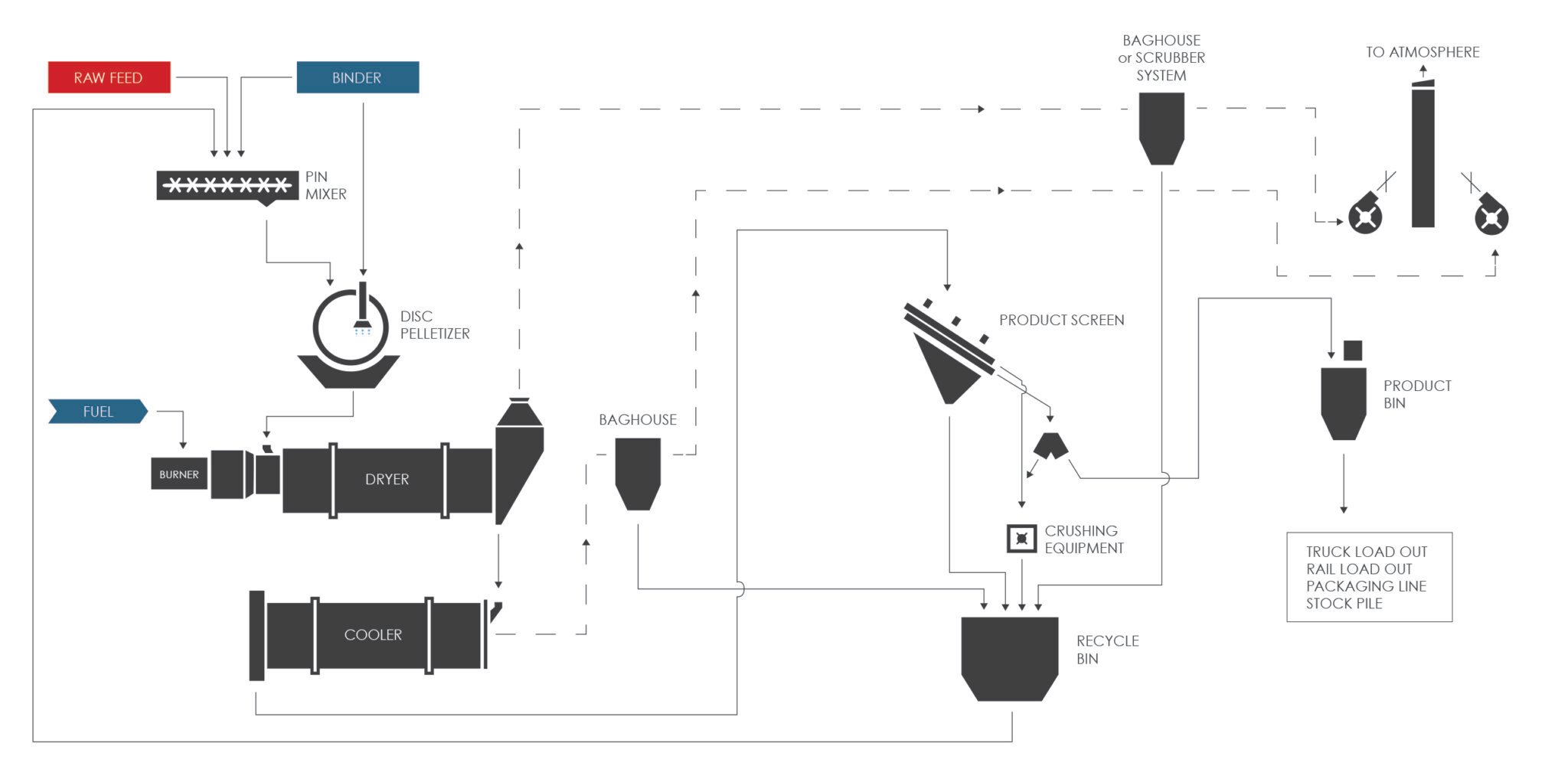

Simplified Process Flow Diagram (PFD) of a pin mixer – disc pelletizer setup

How the Catalyst Pelletizing Process Works

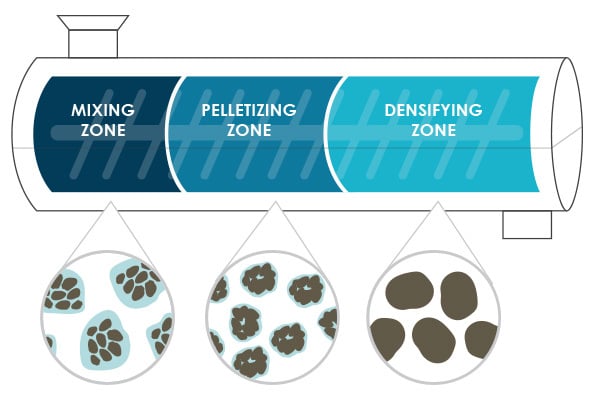

Raw material is fed into the pin mixer. Inside the enclosed mixer trough, a shaft fitted with pins rotates at several hundred RPMs. Binder spray ports, strategically located along the top of the mixer’s interior, distribute the binding agent over the spinning bed of material, causing the fines to become tacky. As a result of the tackiness paired with the intense spinning action, the fines begin to coalesce into small agglomerates or “seed pellets,” which, upon reaching the desired size, exit the mixer. All of this occurs in a matter of seconds.

Illustration showing the pin mixer zones and how fines are converted into seed pellets as they move through the unit

The discharged pellets are then fed onto the disc pelletizer, which consists of an angled rotating pan or disc. Here, additional fines and binder are fed and sprayed respectively over the rotating bed of material, allowing the seed pellets to continue collecting layers of material and becoming enlarged to the desired size, at which point they exit the disc via centrifugal force.

Diagram illustrating disc pelletizer operation

This process is highly flexible, offering a number of variables that can be adjusted to fine-tune pellet formation and is a favored approach for this reason.

Because of this flexibility, the pin mixer – disc pelletizer approach is capable of producing granules with a range of physical qualities, with catalyst producers often focusing on:

- Attrition

- Crush strength

- Compression strength

- Flowability

- Moisture content

- Bulk density

- Porosity

Tungsten pellets produced in the FEECO Innovation Center using the pin mixer + disc pelletizer setup

As an alternative to the pin-disc configuration, pelletizing may also be carried out in a granulation drum. This approach yields slightly less spherical granules and does not offer the same level of control and refinement. However, it produces rounded granules at a much higher throughput.

Upon pelletizing, the pellets are dried, typically in a rotary dryer, the rolling action of which promotes further polishing. If the pellets contain the active catalyst component, they can move directly on to calcination. A cooling step may also be employed after drying and/or calcination to allow immediate handling or bagging of the product.

If the granules do not contain the active catalytic component, an impregnation stage may follow, often at a separate facility. Impregnation involves spraying the active catalytic component onto the support granules in a rotary coating drum impregnator.

Following impregnation, the catalyst will require drying to remove any remaining solvent, and calcination to chemically bond the active component onto the support.

When is Pelletizing Not a Fit?

In cases where the material responds favorably to pelletizing, there are a few factors that might discourage the use of this approach:

Low Binder Inclusion

The chemistry behind some catalysts may exclude or significantly limit the use of a binding agent, which is key to the success of a wet granulation process.

Similarly, the binding agent that performs best may not be tolerable at the quantity required for optimal pellet formation.

In this case, an alternative approach may serve catalyst production better.

High Surface Area

While spherical granules generally boast a higher surface area compared to some other shapes, in some cases the desired surface area may not be achievable.

Mechanical Strength

Agglomerate strength can be increased or decreased to some extent, but the packing requirements of a specific application may demand an agglomerate stronger than what can be produced using the pin-disc method.

For example, taller fixed bed reactors demand a higher mechanical strength of catalysts, as the granules toward the bottom must bear the weight of the granules on top.[2]

Are Pelletized Spheres Right for my Catalyst Manufacturing Process?

Pelletizing can clearly offer a number of benefits for producers utilizing spherical granules, but as we’ve mentioned, it’s not always a fit, and whether the desired results could be achieved with the technique is not always clear.

For this reason, FEECO offers extensive testing capabilities in our Innovation Center. Process experts can assess feasibility, establish basic process parameters, develop the criteria necessary for equipment scale-up, and even produce small samples for testing trials. Both batch- and pilot-scale equipment are available for testing, which can also be conducted as a continuous process loop.

One particularly advantageous aspect of utilizing the Innovation Center is that drying and calcination testing can also be carried out, giving catalyst producers the opportunity to evaluate the entire catalyst manufacturing process.

Conclusion

In conclusion, spherical catalysts produced through pelletizing can offer significant advantages across a range of catalytic processes. Their optimized geometry promotes improved flow dynamics, minimal pressure drop, and enhanced catalyst dispersion, all of which contribute to greater efficiency and catalyst longevity. The pelletizing process allows precise control over critical physical properties like attrition resistance and mechanical strength, making it an ideal solution for the demanding conditions of modern chemical operations.

While pelletizing may not be suitable for every application, FEECO’s extensive testing capabilities help determine whether this process is a good fit. Our Innovation Center offers the ability to conduct feasibility studies, develop process parameters, and test drying and calcination methods to ensure optimal performance. With our custom equipment and process expertise, FEECO continues to support catalyst producers in driving performance and efficiency across various industries. To find out if pelletizing is the right fit for your catalyst manufacturing goals, contact us today!

SOURCES:

- Griffiths, A., Boyall, S. L., Müller, P., Harrington, J. P., Sobolewska, A. M., Reynolds, W. R., Bourne, R. A., Wu, K., Collins, S. M., Muldowney, M., & Chamberlain, T. W. (2023). MOF-based heterogeneous catalysis in continuous flow via incorporation onto polymer-based spherical activated carbon supports. Nanoscale, 15(44), 17910–17921. https://doi.org/10.1039/d3nr03634k

- Averill, B. A., & Santen, R. A. van et al/ E. (1999). Catalysis: An integrated approach. Elsevier.

- Twigg, M. V. (1996). Catalyst Handbook (2nd ed.). CRC Press.

- Hartmann, V. L., Obysov, A. V., Dulnev, A. V., & Afanas’ev, S. V. (2011). New basic shape of catalysts for natural gas reforming reactors. Chemical Engineering Journal, 176–177, 102–105. https://doi.org/10.1016/j.cej.2011.08.031

- Geerts, Lisa & Geerts-Claes, Hannelore & Skorikov, Alexander & Vermeersch, Julie & Vanbutsele, Gina & Galvita, Vladimir & Constales, Denis & Chandran, C. Vinod & Radhakrishnan, Sambhu & Seo, Jin Won & Breynaert, Eric & Bals, Sara & Sree, Sreeprasanth & Martens, Johan. (2021). Spherical Core-Shell Alumina Support Particles for Model Platinum Catalysts. Nanoscale. 13. Just Accepted. 10.1039/D0NR08456E.

- Erfan, M. (2014, September 18). Spherical catalyst supports .

- Quinta-Ferreira, R. M., Simões, P. M., & Rodrigues, A. E. (1995). Simulation of tubular reactors packed with large-pore catalysts with spherical geometry. Computers & Chemical Engineering, 19, 351–356. https://doi.org/10.1016/0098-1354(95)87062-8

- Farsi, Ado & Xiang, Jiansheng & Latham, John-Paul & Carlsson, Mikael & Stitt, E. & Marigo, M.. (2016). Simulation and characterisation of packed columns for cylindrical catalyst supports and other complex-shaped bodies.

- Chaplin, Brian & Shapley, John & Werth, Charles. (2009). Oxidative Regeneration of Sulfide-fouled Catalysts for Water Treatment. Catalysis Letters. 132. 174-181. 10.1007/s10562-009-0083-z.