Agricultural operations face a number of obstacles when working to optimize crop production. One of the biggest issues they face is maintaining a high-quality, balanced soil. A common soil issue that frequently occurs is low pH, which leads to poor nutrient absorption. This issue is resolved by applying a lime soil amendment. Lime’s impressive ability to correct soil acidity can be found in a number of products, but one product gaining increased attention over more traditional products is pelletized lime. In fact, many ag operations are quickly learning why limestone pellets are both a problem-solving product and a beneficial game-changer when dealing with soil pH-related issues.

Types of Lime

Before highlighting the benefits of pelletized lime, let’s first review commonly used lime products:

Ag Lime

Agricultural lime, or ag lime, is a crushed, coarse limestone product used in agricultural applications.

Powdered Lime

Powdered lime is created when crushed limestone rock is further processed into a finely ground, powdered product.

Pelletized Lime

Pelletized limestone, also known as pelletized lime, results from crushing limestone rock into a powder and then pelletizing the material. By undergoing pelletization, the product is easy to handle, while still maintaining the quick-dissolving benefits found in powdered lime.

Quicklime

Quicklime is created by heating limestone. It raises pH very quickly but can damage plants if used at incorrect application rates or at times of the year when plants are sensitive. Also, it can be potentially harmful to people-application needs to be done with care.

Hydrated Lime

Hydrated lime is created when quicklime is mixed with water. This product raises pH quickly, but can also be harmful to plants and people if used incorrectly.

Liquid Lime

Liquid lime is a mixture of lime and water. Consumers using this product often experience under-liming and require more frequent lime applications. In addition, liquid lime incurs higher application costs because both water and lime are being transported.

Ag operations have many lime options to choose from and time and money are of the utmost importance. Ag lime is by far the most commonly used lime product in ag operations, but as more operations begin to see the benefits of pelletized lime over the other types, they are quickly switching over to pelletized lime. For a more in-depth comparison of these products, see Pelletized Lime vs. Ag Lime (and Other Imposters).

Why is Pelletized Lime Better than Non-Pelletized Alternatives?

Lime’s ability to effectively alter soil conditions is directly related to the applied product’s size and quality of limestone being used. Smaller particles create an increased total surface area exposed to the soil’s acidity, providing the necessary neutralization benefits to raise soil pH and improve soil conditions. Smaller particle size also contributes to faster breakdown and neutralization results versus other lime applications.

So what does this mean for the lime amendments most often used in agricultural operations? For ag lime, its inconsistent sizing and coarse particles require more time to break down, usually 3-5 years, making results difficult to anticipate and optimum crop production slow to occur. Although powdered limestone looks to have the smallest particle size, it is unable to provide quality soil improvements due to its handling issues. Powdered lime is difficult to accurately apply, because it can easily blow into undesired areas, resulting in messy, ineffective, and wasteful applications. Quicklime and hydrated lime work quickly, but can be damaging to plants and as mentioned, can be harmful to those handling it.

The best lime solution for agricultural operations is pelletized lime. While all lime application products work to improve soil conditions, pelletized limestone is the quickest, most consistent, and most effective solution for raising soil pH. Even better, the benefits incurred from a small particle size are maintained in pelletized lime, because the pellets break down easily. The consistent pellet size also allows for accurate applications and easy-to-anticipate neutralization results. In addition, handling issues associated with powdered lime, quick lime, and hydrated lime are prevented, because limestone pellets are easy to transport and apply. Other pelletized lime benefits include:

-

- Increased nutrient absorption

- Improved water retention

- Bigger root systems in plants

- Reduced soil erosion

- Decreased occurrence of soil crust formations

- Maintained soil aggregate structure

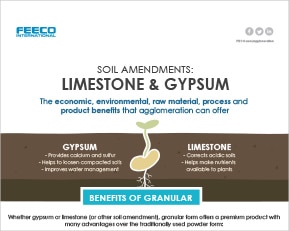

Click the image below to view our infographic on limestone soil amendments

In addition to the benefits that pelletized lime naturally offers, pelletizing lime also offers the opportunity to create an enhanced, premium product. Additives such as micronutrients and organic acids can be added during processing to create an all-in-one pellet that contains everything needed to meet desired crop production needs.

The Limestone Pelletizing Process

The limestone pelletizing process can be broken down into three steps: preconditioning, pelletizing, and drying.

Preconditioning

When pelletizing limestone, a preconditioning step is not required, but is often used, because it offers a wide range of benefits, including increased production, reduced binder requirement, and a more uniform product. For more information on the potential benefits, see our article, The Benefits of Adding a Pin Mixer to a Limestone Disc Pelletizing Operation.

Preconditioning is carried out in a pin mixer, which uses an intense spinning action to homogeneously combine crushed limestone with a liquid binder. Preconditioning produces a uniform mixture for the disc pelletizer, while also forming seed pellets.

Pelletizing

Seed pellets exiting the mixer are fed onto the disc pelletizer (also known as a pan granulator). Additional binder and fines are fed onto the disc pelletizer, causing the seed pellets to become tacky and pick up additional fines as they tumble, growing in similar fashion to a snowball. For operations that do not employ a preconditioning step, the preceding mixer is simply omitted, with binder and crushed limestone fed directly onto the disc pelletizer.

Drying

Once pellets have reached the desired size, they are discharged from the disc pelletizer and fed to a rotary dryer. The rotary dryer reduces the moisture content of the granules to a predetermined level, leaving them in their final form. A cooler may follow the rotary dryer if necessary.

Rotary dryers utilize direct contact with a heated air in combination with a tumbling and cascading action to efficiently dry limestone pellets.

Conclusion

With so many benefits and improvements, it’s no wonder that countless agricultural operations have turned to pelletized limestone to solve their soil pH issues. FEECO is the leading provider of limestone pelletizing equipment, with an on-site testing facility for process and product development.

For more information, contact us today!