The value of gypsum pellets as part of an integrated systems approach to soil management has received increased attention and recognition over the last few decades. As a result, more and more questions have come up regarding gypsum processing equipment and how to effectively manufacture gypsum pellets. Whether you are curious about the benefits of gypsum pelletizing or want to learn about the equipment used to manufacture gypsum pellets, read on to discover more about the value gained from gypsum pelletizing.

The Basics of Gypsum Pelletizing

Gypsum pelletizing forms a strong pellet capable of breaking down quickly in standard field conditions. In order to form quality pellets, three critical pieces of gypsum processing equipment are required: a pin mixer, gypsum pelletizer, and rotary dryer.

Gypsum Processing Equipment

-

- A Pin Mixer imparts an intense motion on the powdered gypsum and binder. The resulting mixture is dense, with the air and water volume between particles being reduced or eliminated. This step conditions the material for the gypsum pelletizer.

-

- The Gypsum Pelletizer, also known as a disc pelletizer, tumbles the material on a rotating disc. This motion ‘grows’ the gypsum mixture into pellets, similar to the way a snowball is gradually built.

-

- After the pellets are formed, a Rotary Dryer is used to shower the gypsum pellets through an air stream using the rotating motion and flights within the rotary dryer. This step removes moisture from the gypsum pellets and promotes both uniformity and quality in the final product.

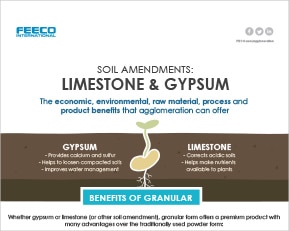

Click the image below to view our infographic on gypsum soil amendments

Why Pelletize Gypsum?

Although it’s been used as a supplement to agricultural practices for centuries, gypsum has not always been easy to apply, handle, or store. Gypsum pelletizing is a perfect solution to such issues, providing benefits such as:

-

- Dust-free product handling

-

- Improved product formulations

-

- Simplified transportation and field spreading

Uses for Gypsum Pellets

Gypsum is an ideal agricultural resource because it improves the properties of soil and promotes optimal crop growth. In addition to the benefits created from pelletizing gypsum, there are many advantages to regularly using gypsum pellets for agricultural purposes:

1. Increased Plant Nutrition

Gypsum pellets are composed of calcium sulfate. When applied to a field, gypsum pellets supply calcium and sulfur, two essential nutrients that increase crop yield and stimulate root growth.

2. Water Infiltration

Gypsum pellet applications improve a soil’s ability drain and move water efficiently.

3. Improved Soil Structure

By reducing soil aluminum toxicity, gypsum can improve acid soils and allow for increased root growth in crops. Gypsum applications also loosen compacted soil and clay, improve soil aggregation, and increase the overall permeability of the soil.

4. Erosion Relief

Gypsum prevents the runoff of phosphorus and other nutrients from fields, making it an economical way to stop non-point runoff pollution. Gypsum pellets also improve water infiltration rates.

5. Pond Remediation

Gypsum pellets can be used to treat pond water issues such as cloudiness attributed to an overabundance of suspended clay.

FEECO is a leader in gypsum manufacturing and gypsum processing equipment. Additionally, our unique lab facilities provide feasibility testing that ensures customers receive a complete gypsum solution. For more information on the value of gypsum, contact us today!