Catalysts are an invaluable tool in many industrial processes, helping to facilitate reactions between materials. They are so important in fact, that some experts estimate they are responsible for 85-90% of products in the chemical industry.¹

As the role of catalysts in industry continues to grow, catalyst production research and development is on the rise, with producers looking to improve existing products and develop new ones.

Factors Driving Catalyst Demand

Like many industries, a complex relationship between many factors is responsible for driving the demand for catalysts. Some of these factors include:

Growth in Applications

As such a valuable tool, catalysts continue to see growth in the applications to which they are applied. One sector that is especially suited to demand growth is the use of catalysts in the production of fine chemicals and pharmaceuticals, where they play a critical role in selective synthesis.²

Growth in Established Applications

Catalysts are already well established as a tool in many industries. As developed countries continue to prosper and expand, and developing regions push further industrial growth, the need for catalysts in many already established applications continues to grow.

One industry in which this is particularly exemplified is in petroleum refining – the industry currently responsible for the largest demand on catalysts. Increasing refinery capacity and fuel demand are also driving an increase in demand growth for catalysts.³

Increased Focus on Sustainability

An increased focus on sustainability has prompted a surge in environmental regulation and efforts to curb environmental risks.

This has fostered a growing demand for catalysts that can be used in such applications. This is especially true in reducing contaminants in refinery products.²

Whether preparing CO2 for use or sequestration, removing volatile organic compounds (VOCs) in air pollution control efforts, or aiding in efforts to develop alternatives to fossil fuels, catalysts have become a key tool in environmental protection, with a wide range of applications in the field.

Advancing Production and Technology

The importance of reducing costs, maximizing efficiency, and improving end products continues to be a central focus in many different industries.

As a critical tool in improving reactions, catalysts play a vital role in this endeavor, whether that be in producing more effective products and materials, or in maximizing the efficiency of reactions.

R&D Around Catalyst Production

The catalyst industry is extremely diverse; in addition to optimizing existing catalysts, producers are constantly looking to develop new catalyst products with precise characteristics to meet the exact needs of a given application. As such, the catalyst production industry is seeing a flurry of research and development aimed at these objectives.

Various physical and chemical properties of catalysts can be adjusted and fine-tuned to produce a product that will be optimized for its intended application – yielding hundreds of catalyst product possibilities. With so many possibilities and potential applications, research and development is pivotal to success. According to the Rutgers Catalyst Manufacturing Science and Engineering Consortium, catalyst production has historically not seen a focus in the academic world, leading to sub-par catalyst design and manufacturing.

For this reason, high-quality research and development around manufacturing better catalyst products has gained an increasing amount of attention.

There are three key aspects to the success of a catalyst product, each with a significant influence on the performance, reliability, and longevity of the product:

- Formulation

- Agglomeration

- Calcination

Formulation:

Catalysts are made up of a variety of materials and combinations of such in order to suit the intended application.

Formulation often focuses on reducing/minimizing emissions, optimizing the intended reaction, maximizing re-usability, and mitigating the production of any potential byproducts. Zeolites and alumina are frequently utilized catalyst substrates. Catalyst formulation is a highly proprietary endeavor.

Once catalyst formulations have been established, testing can begin on creating the catalyst product itself.

Agglomeration

Agglomeration, or particle size enlargement of a catalyst powder serves many purposes.

Since most catalysts are produced in an indirect-fired rotary kiln, agglomeration helps to reduce entrainment and promote heat transfer in the material bed.

Agglomeration is also used to improve the performance of the end product; using a rounded granule is common, because rounded granules allow for ideal flow of the material through the catalyst bed, due to the void spaces between particles. Similarly, rounded granules are ideal for minimizing attrition (the breakdown of particles into fines and dust).

Agglomeration of a catalyst can be a highly customizable endeavor; characteristics such as particle size distribution, mechanical strength, shape, and more can all be fine-tuned during the agglomeration process to meet exacting specifications. While many methods of agglomeration are available, here, we’ll focus on producing rounded granules, as these are the most common form of catalysts.

In most cases, rounded catalyst granules are produced in a pelletizer plant comprised of a pin mixer and disc pelletizer (pan granulator) combination, or a disc pelletizer alone. Testing is critical to determine the ideal equipment selection and work out the many process variables in order to produce a product with the intended characteristics.

3D Model of a FEECO Disc Pelletizer

Agglomeration is often likened to a blend of science and art; it takes an experienced hand to consistently produce a product with the target qualities. Agglomerate characteristics that are most often targeted when producing a catalyst product include:

- Particle size distribution

- Mechanical strength

- Shape

- Attrition

- Bulk Density

- Ability to “hold up” in a rotary kiln

- Surface area

- Packing density

- Bed permeability

The factors below can all be used during the agglomeration process to influence the end product characteristic of the catalyst granules:

- Equipment choice

- Binder formulation

- Binder feed rate

- Material feed rate and location

- Pan speed

- Pan angle

- And more…

Calcination (Curing)

Once the catalyst has been agglomerated, it must be cured. Curing via a thermal process known as calcination hardens the granules into their final form. This adds mechanical strength to the catalyst for shipping and also assures that the catalyst doesn’t break or crush when loaded into the catalyst vessel.

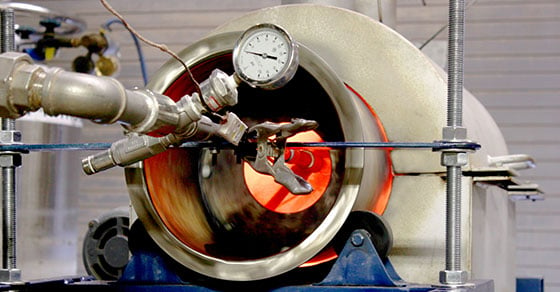

Calcination is most often carried out in an indirect-fired rotary kiln (also referred to as a calciner), which utilizes contact with the shell of the drum to pass heat to the material within, unlike direct-fired kilns which utilize direct contact between the material and combustion gas to heat material to the required temperature.

3D Model of a FEECO Indirect-Fired Kiln (Calciner)

Characteristics that are most often targeted when producing a catalyst product in a rotary kiln include:

- Moisture content

- Surface area

- Mechanical Strength

These characteristics are influenced by finding the right combination of:

- Residence/Retention time

- Temperature profiles

- Internal kiln atmosphere

- Rotational speed

- Method of heating (direct or indirect)

- And more….

High temperature thermal processing is a highly technical endeavor, requiring significant expertise in advanced thermal processing techniques.

The optimized agglomeration and thermal processing techniques combine to create a catalyst with precise mechanical strength, shape, particle size distribution, and more. These factors ultimately influence the overall performance, longevity, and efficiency of the end catalyst product.

The FEECO Innovation Center

As can be seen, process and product development around catalysts is paramount to producing a product that performs as desired. While there may be a variety of testing facilities on the market, none offer the advantage that the FEECO Innovation Center does: the Innovation Center can accommodate both agglomeration and calcination testing methods individually, as well as as a continuous process loop integrating both techniques. This provides a “one stop shop” for catalyst producers looking to optimize an existing catalyst, or develop a new one.

The Innovation Center, staffed by experienced process engineers, is equipped with everything needed to work out the intricacies of each process component, as well as how they will combine as a continuous process to create the desired product.

FEECO Indirect Pilot Kiln used for testing in the Innovation Center

Data gathered from testing is then used to engineer the agglomeration and thermal processing equipment needed to carry out production at commercial scale. This provides producers with the confidence of a well-developed catalyst.

Conclusion

Catalysts are integral to the production of many chemicals and products that growing societies depend on. Their increasing applications and the ongoing effort to improve existing catalysts has prompted a flurry of activity around catalyst research and development.

FEECO is a leader in agglomeration and thermal processing techniques. Our extensive expertise, combined with our state-of-the-art testing facility provides catalyst producers with an unmatched process and product development and optimization experience. We can also engineer and manufacture the equipment needed to carry out the process at commercial scale. For more information on our catalyst capabilities, contact us today!