Potassium and ammonium salts are essential in supplementing crop nutritional requirements. While the granulation of these materials has traditionally been carried out via roll compaction, the demand for a more round and less angular product is causing some fertilizer producers to introduce an additional production line into their operations: pelletizing (wet granulation) with a disc pelletizer.

With many benefits over granules produced via roll compaction, pelletizing allows fertilizer producers to include a higher-value product as part of their offerings, meeting the growing demand for high-quality and specialty fertilizers.

The Switch to Pelletizing

Roll compaction, a dry approach to granulation that employs extreme pressure in order to adhere fines together, forms jagged, irregularly shaped particles within the desired size range.

Roll compaction has remained the preferred method for agglomerating potassium and ammonium salts because it offers low operating costs and is a good fit for the self-adhering characteristics of these materials; historically, when producers attempted to process potassium and ammonium salts via wet granulation techniques, the material would form a wet crystalline pulp instead of the desired granules.

Today, advancements in the understanding of these materials and wet granulation principles are opening up new opportunities for products such as:

- Potassium Sulfate or Sulfate of Potash (K2SO4, or SOP)

- Potassium Chloride or Muriate of Potash (KCl, or MOP)

- Ammonium Sulfate (AS)

- Other ammonium salts

And as crop nutrition becomes increasingly specialized and application specific, and the standard for fertilizer quality increases, many farmers are willing to pay a little more for the significant benefits a round fertilizer granule can offer, opening the door to a new market for producers.

Note: When ammoniation is required, such as in the production of ammonium nitrate, or ammonium phosphate nitrate, ammoniation should be carried out in reactors prior to the disc pelletizer to avoid high fuming and ammonia loss. For this reason, the disc pelletizing approach is not commonly utilized if ammoniation is involved, with producers opting for a rotary drum granulator instead.

Potash fines before and after agglomeration on a disc pelletizer

Benefits of Spherical Over Angular Fertilizer Granules

Pelletizing creates a more spherical, uniform granular product that boasts many benefits over the angular granules produced via roll compaction. This includes:

Improved Handling & Application

Compared to angular granules that exhibit poor rheology, round granules are inherently more flowable. This enhanced flowability improves handling at every stage of the product life cycle, from load-out and storage, all the way through to application.

Round granules also spread more uniformly than jagged ones, improving application accuracy, nutrient distribution, and the predictability of results.

Reduced Dust & Attrition

One of the ways in which handling is greatly improved with round granules is through the reduction in dust. The angled edges of granules from a roll compactor are prone to rubbing together and breaking down into fines, generating dust (attrition). Though some production methods exist to reduce the opportunity for dust generation with compaction granules, these techniques increase production costs and still do not compare to the minimal dust generation of round granules, which stay intact because there are no harsh edges to rub together and break away.

Improved Product Variability

The flexible nature of the pelletizing process allows for greater product variability. The pelletizing process is highly pliable and can accommodate multiple additives in the form of both liquids and solids. This flexibility allows producers to easily include beneficial additives such as micronutrients, organic binders, coatings, and more, to enhance the formulation. The process also provides the opportunity for operators to easily adjust sizing or density characteristics.

Faster Nutrient Delivery

Round granules are less dense than a compacted granule and hold the potential to improve product performance by breaking down faster than compaction granules, promoting quicker nutrient delivery.

Reduced Coating Agent

Coating is becoming an increasingly popular approach to modifying fertilizer formulation, as well as handling and performance characteristics, whether coating to decrease potential for caking, reduce dust, control release rate, include micronutrients, or otherwise.

The round shape produced by the pelletizing process is ideal for fertilizer coating, because it has a lower surface area to volume (SAV) ratio than irregularly shaped granules, allowing producers to use less coating agent.

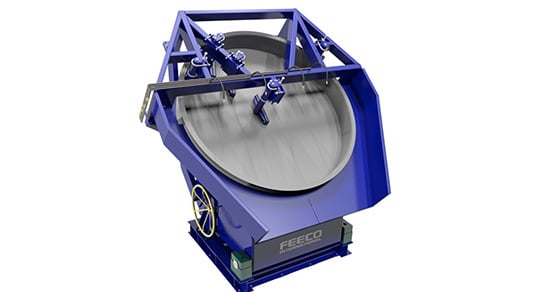

Pelletizing Potassium & Ammonium Salts With a Disc Pelletizer

While the pugmill mixer and drum granulator are widely used to carry out wet granulation in the fertilizer industry and certainly offer an effective processing solution, producers are turning to the disc pelletizer in particular for a few reasons:

Low Recycle = High Efficiency

One of the most enticing aspects of the disc pelletizer approach is the efficiency the process offers. Also known as a pan granulator, the disc pelletizer naturally classifies material on the rotating pan according to particle size.

Classification allows operators to target and spray the liquid solution/binding agent to promote growth only on undersized material, largely eliminating the production of oversized particles and reducing the amount of moisture required by the process. This classification action also generally gives operators better control over refining particle size, allowing them to make adjustments to fine-tune particle size or pellet growth during production.

This significant reduction in the amount of recycle makes the process much more efficient, because far less recycle material has to be dried.

Refined Product

The disc pelletizer produces a more refined granule compared to other methods, particularly when a pin mixer is employed as a preconditioning step.

The pin mixer produces a homogeneous mixture of solid and liquid components, while also forming small seed pellets for use as feedstock to the disc. This leaves the disc pelletizer with the sole job of growing and rounding the seed pellets.

The result is a well-mixed, dedusted feed to the disc that creates a more uniform, spherical granule.

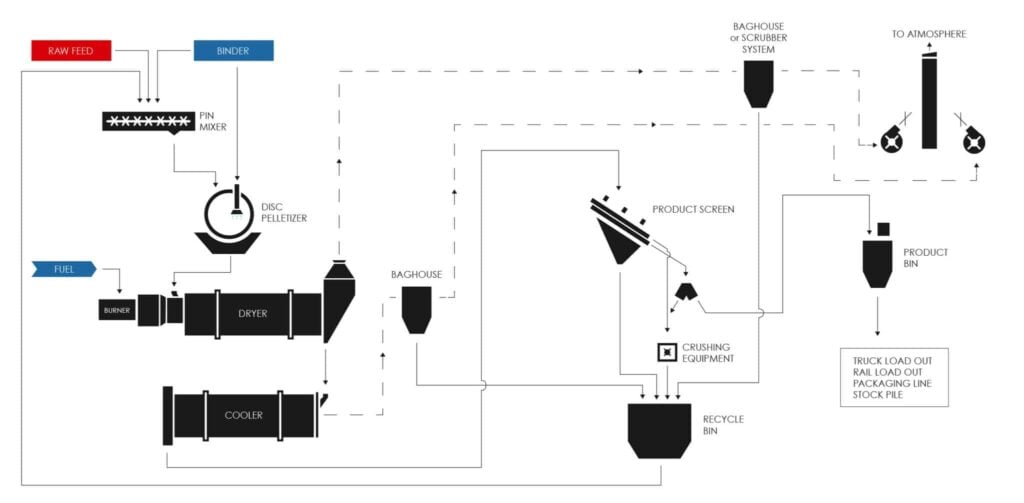

The Pelletizing Process

The pelletizing process varies depending on the unique material being processed and the specific goals of the operation. A typical continuous pelletizing setup is outlined here.

Flow diagram illustrating a typical pin mixer-disc pelletizer setup

Preconditioning

As mentioned, a pin mixer is often used to precondition material prior to the disc pelletizer. Here, fines, liquid binder, and any additives are homogeneously mixed into a uniform mixture. As the mixture moves through the pin mixer, dense seed pellets begin to form.

Pelletizing

Seed pellets from the pin mixer are fed onto the disc pelletizer. Additional fines and binder are continuously added. As the seed pellets pass through the fines and binder, they become tacky, picking up more fines. As they continue this process while tumbling on the rotating disc, seed pellets are grown in a layering effect known as coalescence.

Once pellets reach the desired size, centrifugal force causes the smaller under-size pellets to be carried around and remain on the disc pelletizer to continue to grow while the larger on-size pellets discharge from the disc. From the disc, the on-size pellets are fed to a rotary dryer.

3D Model of a FEECO Disc Pelletizer

Drying & Cooling

Pellets are dried in the rotary drum dryer, bringing them within the desired moisture range of the end product. The rotation of the rotary drum further tumbles and polishes pellets. If necessary, a rotary cooler follows the dryer, reducing the temperature of the material for bagging or handling.

Product goes through a screen, sorting out over- and under–size pellets, which go back into the process as recycle (with over-size being crushed first). On-spec product moves on to packaging, storage, or loadout. A coating step may also be utilized on finished granules at this stage as well.

Potassium sulfate processed via wet granulation/pelletizing using the pin mixer-disc pelletizer setup

Testing the Pelletizing Process

All materials (and often the same material from different sources) respond differently to agglomerative granulation, making testing a critical component in developing a successful pelletizing line. The challenging nature of agglomerating potassium and ammonium salts via wet granulation further amplifies this need.

Through batch- and pilot-scale testing such as that conducted in the FEECO Innovation Center, various aspects of the pelletizing process can be evaluated to identify the necessary parameters for a successful scale-up. This often includes:

- Process variables such as feed rates, binder concentration, spray and feed locations, and more

- Inclusion of beneficial additives

- Whether or not a preconditioning step is necessary

- Drying requirements

- Coating parameters

Conclusion

While potassium and ammonium salts have remained well served by the roll compaction method of granulation, the growing demand for a more premium product, paired with advancements in wet granulation principles, as well as the many benefits offered by pelletizing, is encouraging many fertilizer producers to adopt the pelletizing technique alongside their existing operations for products such as potassium sulfate, potassium chloride, ammonium sulfate, and more. Testing plays a vital role in the successful development of these commercial-scale pelletizing lines.

FEECO is the global leader in tumble growth (non-pressure or agitation) agglomeration and fertilizer production techniques. Our decades of experience in process and product development, custom equipment manufacturing, and parts and service support services have made us the go-to resource for the industry. For more information on pelletizing potassium and ammonium salts, or our custom pin mixers and disc pelletizers, contact us today!