Pelletized limestone is commonly used as a soil additive for agricultural purposes. Composed of calcium carbonate, this mineral neutralizes a soil’s acidity, raises the pH level, and improves the absorption of soil nutrients. While limestone is available in powdered form for agricultural applications, this formulation is dusty and difficult to manage. In order to truly reap the benefits of limestone as a soil additive, a limestone pelletizing process is recommended.

Benefits to Pelletizing Limestone

Limestone pelletization offers many advantages in terms of improved end product benefits.

Easier Handling:

Powdered limestone is very dusty, making it a difficult product to handle. Utilizing a limestone pelletizing process creates a final product that is easier to store and apply.

Reduced Waste:

Crushed limestone is easily wasted when applied to fields because the wind often carries product away from the targeted field application. In contrast, pelletized limestone is delivered exactly where it is needed. Additionally, the uniform shape supports even application of limestone pellets.

Enhanced Nutrient Delivery:

The round, uniform pellet shape produced by pelletizing limestone easily breaks down to deliver nutrients quickly.

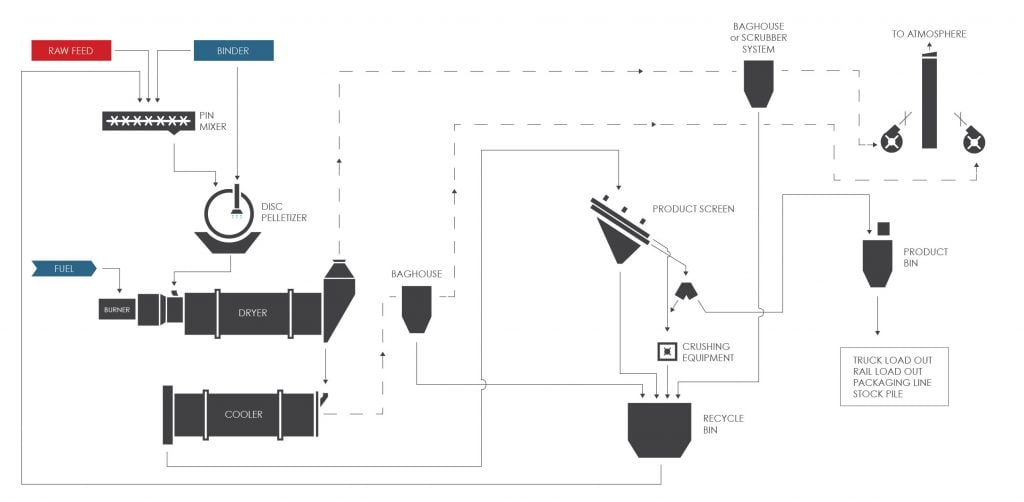

Process Overview

The following steps outline a typical limestone pelletizer plant and the equipment used:

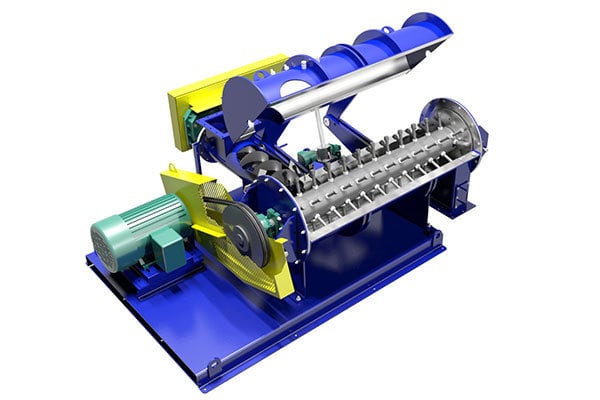

Pre-Conditioning

Mined limestone is first crushed into a fine powder. If necessary, a rotary dryer is used to dry the mined limestone before it is crushed. Next, a raw material feed bin is used to introduce the crushed limestone to the pelletization process. A pin mixer uses an intense spinning action to combine the limestone and binder, resulting in a densification within the material and a reduction of air and water volume between particles. While pin mixers are not always used, systems employing this limestone processing equipment have a higher throughput, use less binder, and yield more pellets in the desired final size range.

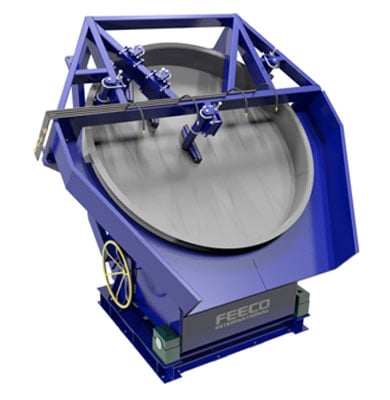

Pelletization

The limestone mixture is fed onto a disc pelletizer (pan granulator) where it undergoes tumble growth agglomeration. If a pre-conditioning step were not utilized, this is where the pelletizing process would begin. The limestone builds and grows gradually as it rotates on the disc, with material and moisture being fed at a controlled rate.

FEECO disc pelletizers are flexible, allowing users to control the final size of the pellet with variables such as disc angle and speed. Moreover, because this process is considered both an art and science, FEECO also provides training to ensure customers will be able to produce ideal results from their limestone processing equipment.

Product Finalization

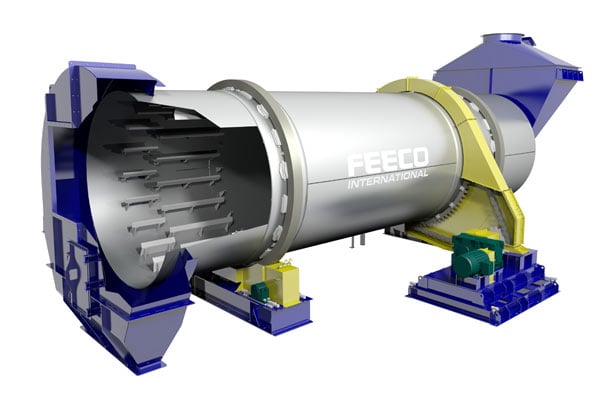

The limestone pelletizing process adds moisture to the pellets, making drying a necessary step before storing or bagging the product. Rotary dryers are a common drying choice due to their efficiency and ability to handle a high amount of volume and variability in feedstock. Flights within the dryer lift and cascade the limestone pellets as they travel through the dryer’s rotating drum, creating an effective drying motion, while also preventing clumps.

Similarly, if cooling is required, a rotary cooler is commonly used. This equipment provides the same lifting and cascading motion as a rotary dryer, but reduces the temperature of a product using a counter-current air stream. Other drying and cooling equipment options include fluid bed dryers and fluid bed coolers. Both fluid bed coolers and fluid bed dryers suspend material in a fluidized state, exposing the entire limestone pellet surface to air.

Once the material is dried and/or cooled, the limestone pellets are screened by size. Pellets over or under the desired size are recycled back into the limestone pelletizing process while optimally sized limestone pellets are bagged and/or stored.

Click the image below to view our infographic on limestone soil amendments

Important Limestone Pelletizing Elements

A number of factors contribute to the success of a limestone pelletizing process, with two of the most important influences being binder and equipment.

Binder

Limestone pelletizing requires a binder in order to achieve proper pellet strength. If only water were added to form the product, the resulting limestone pellet would be weak. Lignosulfonate is the most common lignin binding agent used when pelletizing limestone. Both calcium-based and ammonium-based lignins are commonly used: the calcium-based lignin adds extra nutrients, while the ammonium-based lignin is a more economic choice.

Equipment

Quality equipment is a must in order to produce the best pelletized limestone product. FEECO supplies a variety of equipment customized to support unique applications such as limestone pelletization. In addition to the equipment described above, limestone pelletizing operations also often utilize:

- Pumping Systems (to pump lignin into a Disc Pelletizer)

- Hammer Mills (for size reduction of recycle)

- Material handling equipment such as Belt Conveyors, Hoppers, Bucket Elevators, and Screw Conveyors

FEECO has been an agglomeration industry leader for over 65 years. With experience in feasibility testing, designing complete engineered systems, and everything in-between, our resources can help you create the right process for your material. For more information on our limestone pelletizing equipment, contact us today!