Although it may seem like a good opportunity for cost savings, a one-size-fits-all approach to rotary dryer design typically yields a dryer that is ill-equipped, resulting in a number of unseen costs associated with product that is under-dried, over-dried, or in most cases, a mix of both.

Rotary dryers are used in every industry from mining and minerals to animal feed and fertilizers. Their widespread applicability often has them mistaken for a blanket design that by good fortune, suits all applications. However, just the opposite is true; the ability of a dryer to consistently produce on-spec product is the result of careful engineering to produce a design tailored to the specific demands of its intended use.

Those considering a one-size-fits-all or standardized approach to rotary dryer design should therefore be aware of the potential issues and costs associated with under and over drying.

Inadequate Rotary Dryer Design: Over-Dried Product

The extent to which over- or under-dried product (or both) will impact a given operation varies considerably, depending on the industry, the material being processed, and the particulars of the production line. These consequences can range from minor inconveniences, to full-blown catastrophes, but in most cases, fall somewhere in between.

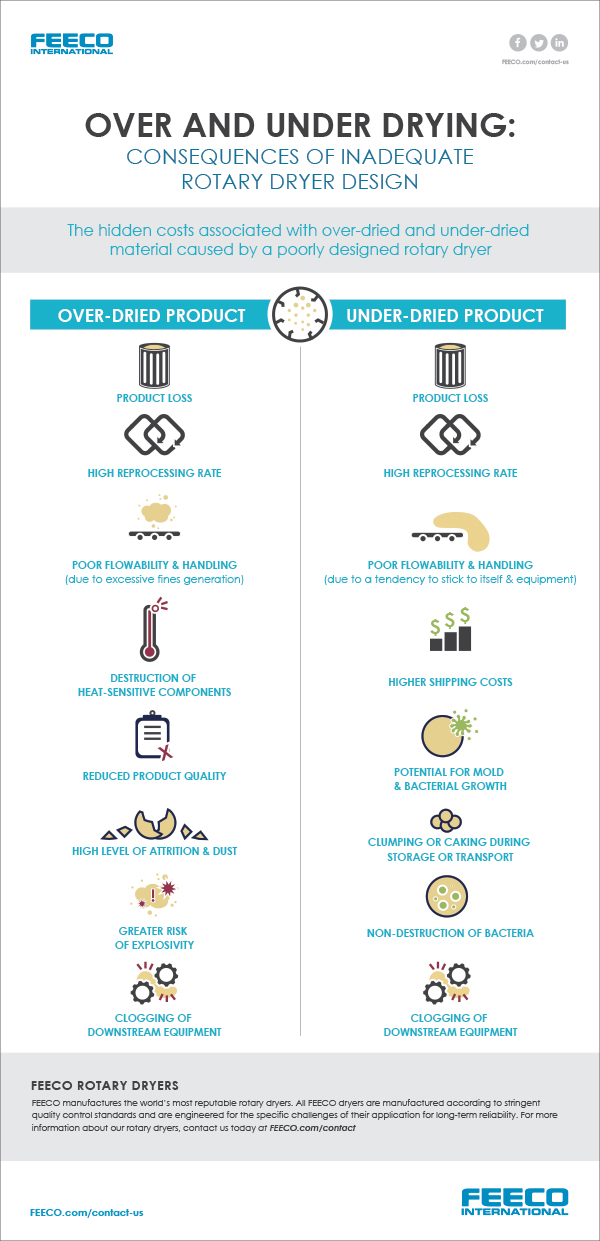

Over-dried product can cause a range of problems downstream, resulting in both direct and indirect costs in the form of:

- Product loss

- A high reprocessing rate

- Poor flowability due to excessive fines generation

- Clogged downstream equipment (again, due to fines)

- A high level of attrition (product degradation) and dust generation

- The destruction of heat-sensitive components

- Reduced product quality

- A higher risk of explosivity

Inadequate Rotary Dryer Design: Under-Dried Product

On the same token, a rotary dryer that does not dry product enough also presents a host of problems. Again, these will depend on what material is being processed, the production line itself, and the industry, but could include:

- Product loss

- Poor flowability and handling, due to a tendency to stick to itself and equipment

- High reprocessing rate

- Increased shipping costs

- Potential for mold and bacterial growth

- Clumping or caking during storage or transport

- Non-destruction of bacteria

- Clogging of downstream equipment

Further complicating matters, the problems mentioned above also tend to present their own compounding sets of challenges as well. Product loss, for example, might equate to missed production deadlines, or higher labor costs to make up for the loss.

Likewise, inferior product that ends up in the hands of customers could result in reimbursement costs, or even a damaged reputation. Clogged equipment often increases labor and operational costs, as increased cleaning and maintenance are typically necessary.

Rotary Dryer Process Audits

While the rotary dryer design process affords the opportunity to address specific material challenges and process goals through customized design, many operators and plant managers are dealing with existing equipment. When operators struggle to consistently produce on-spec product, a rotary dryer process audit may be the key to improving dryer performance. Process audits may be conducted by the original equipment manufacturer or a third-party service provider.

Process audits review the dryer system itself, as well as upstream processing conditions that could be impacting dryer performance. FEECO Customer Service Engineers regularly conduct process audits to resolve processing issues, evaluate a change in capacity, improve efficiency, and more.

Conclusion

One-size-fits-all dryer designs may seem tempting due to their lower upfront cost, but ultimately cost more in the long run in the form of direct and indirect costs related to under- or over-dried product.

In business since 1951, FEECO provides the industry’s most reputable rotary dryers, each with a design optimized around its specific application for efficient processing, consistent on-spec product, and long-term reliability. We also offer a unique testing facility for assessing dryer feasibility and gathering process data necessary for the design of commercial-scale units. For more information on our rotary dryers, testing services, or service support, contact us today!