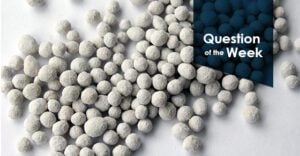

An In-Depth Look at Limestone Pelletizing

Pelletized limestone is commonly used as a soil additive for agricultural purposes. Composed of calcium carbonate, this mineral neutralizes a soil’s acidity, raises the pH level, and improves the absorption of soil nutrients. While limestone is available in powdered form for agricultural applications, this formulation …