As a booming global population and emerging economies put pressure on existing resources, and high grade ores become a thing of the past, mining companies are looking for technologies that will allow them to economically recover target materials, namely metals, from low-grade ore sources. One technology has proven its worth in meeting the changing demands of the mining industry: heap leaching.

The heap leaching technology has seen substantial growth over the past few decades, becoming a key process in mining; NAUE, a group specializing in geosynthetic liners, assesses that over 30% of copper and gold produced each year is beneficiated via heap leaching, up from only about 3% decades earlier.

Benefits of Heap Leaching

Largely due to the economic advantages it can offer, heap leaching has prevailed as the preferred approach to beneficiation in settings where the ore source is low grade, or has been considered uneconomic to process via other approaches.

Heap leaching offers a wide range of advantages, both economic and otherwise, that have undoubtedly contributed to its exponential growth. Among them:

- Low capital investment and operating costs

- Fast payback

- No tailings disposal

- Lower energy and water requirements

- Can be applied to tailings and waste piles

- Viable in a wide range of climates

- Simple setup and operation

In applying the seven questions of sustainability to the heap leaching practice, Mark Smith of Ausenco found that heap leaching has some less obvious benefits to offer as well. Among them:

- The technology used in the heap leaching process can be contracted locally, requiring less reliance on imported technology. This improves opportunity for community engagement.

- Compared to conventional milling, heap leaching facilities generally have far fewer serious acid rock drainage (ARD) problems.

- Heap leaching is less sensitive to changes in commodity pricing, making it a lower risk investment. Furthermore, since more ore (ore with a lower grade cutoff) can be processed, the mine life is often longer, the operation larger, or both.

Heap Leaching: Growth in Applications

Heap leaching has ancient origins, but its capabilities in extracting materials from low grade ore sources have only truly been realized in recent decades, with a constant evolution of the process ongoing.

Heap leaching is most commonly found in the gold and copper industries, but is also gaining acceptance amongst a variety of other materials as well, including:

What the Heap Leaching Process Looks Like:

Crushing & Agglomeration

In heap leaching, mined ore is first commonly crushed in order make the target metal more accessible. The ore fines are then often agglomerated to improve percolation of the leachate through the heap.

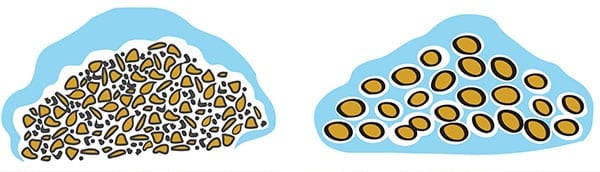

Agglomeration is carried out in an agglomeration drum (ore drum), in which the ore fines are tumbled and sprayed with the lixivant/leachate. The tumbling action combined with the leaching agent allows the ore fines to form into particles that are more uniform in shape and size. As can be seen in the picture below, this uniformity helps to prevent smaller fines from clogging the spaces between larger particles.

This step also serves to create a homogenous mixture of the ore particles and leachate, beginning the leaching process and maximizing efficiency.

Stacking & Irrigation

Once crushed and agglomerated, ore is stacked onto an impermeable pad, creating the “heap.” The heap is then irrigated with the leaching agent, which differs depending on the target metal.

The leachate is then allowed to percolate through the heap, a process which can take anywhere from months to years. As the leachate moves through the heap, the target metal is dissolved into the aqueous solution through chemical reaction with the leachate. The impregnated solution is then collected at the bottom, where it moves on to metal extraction.

Heap Leaching with Solvent Extraction – Electrowinning (SX-EW)

Heap leaching has also gained increased attention as a result of its demonstrated success in being combined with the SX-EW process, most notably in the copper industry.

Solvent extraction – electrowinning is a hydrometallurgical combination of steps that uses reagents to extract the target metal from the solution that is obtained through leaching, and then electrowin that metal in pure form.

ALTA Metallurgical Services Managing Director and Metallurgical Consultant stated in International Mining that “the ability to use heap leaching, together with SX/EW to go from ore to high grade metal at the mine-site, makes it particularly attractive to aspiring juniors.”

This combination has become so commonplace, that the SX-EW process is often referred to as the Leach Solvent Extraction – Electrowinning, or L-SX-EW process.

Conclusion

The ability of the heap leaching process to economically recover metals and other materials from low grade ores, along with the many other benefits it can offer, will likely see it as a continued invaluable tool in the ever-changing mining landscape.

FEECO produces custom agglomeration drums for use in the heap leaching process. Many of the mining industry’s top producers rely on FEECO agglomeration drums, as is evidenced by our presence in some of the world’s largest and most environmentally advanced mines. For more information on our agglomeration drums, contact us today!