Rotary Kiln Maintenance Services in High Demand in Catalyst Industry

In the face of growing demand, catalyst manufacturers are increasingly looking to rotary kiln maintenance programs to avert the escalating costs associated with downtime. Rotary Kiln Maintenance in the Catalyst Market When properly engineered and manufactured, rotary kilns are a reliable processing device, but they …

Resource of the Week: Limestone and Gypsum Soil Amendments Infographic

This week’s highlighted resource is an infographic on limestone and gypsum soil amendments. Limestone and gypsum are both critical soil conditioners that have been gaining in popularity over the years. This infographic covers their capabilities, how they are produced in granular form, as well as …

Photo of the Week: Warped Leaf Seal

This week’s photo shows a warped leaf seal. Extreme heat during a kiln’s operation caused the seal to curl away from the drum, and cool into this deformed shape. It was later replaced by a FEECO Customer Service Engineer. Leaf seals minimize air leakage into …

Resource of the Week: Project Profile on a Gold Ore Belt Feeder

This week’s highlighted resource is a project profile on a gold ore belt feeder. FEECO supplied a custom belt feeder for metering gold ore onto a conveyor at a specified rate for a mining company in South America. Click here to view the profile. To …

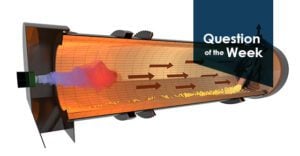

What are the Options in Rotary Kiln Air Flow?

Rotary kiln air flow configuration is an important consideration in kiln design. Counter current and co-current are the different types of air flow options available, each offering distinct advantages and disadvantages. In co-current air flow configuration, the material and process gas flow in the same …