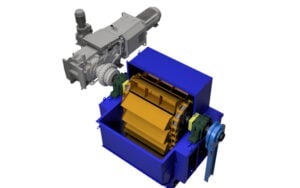

Rotary Dryer Parts and Components Glossary

Rotary dryers are essential to many bulk solids processing and handling operations, reducing the moisture content of both raw materials and finished products. About Rotary Dryers Rotary dryers use a tumbling action in combination with a drying air in order to efficiently dry materials. Most …