Material Characteristics to Consider when Pelletizing Limestone

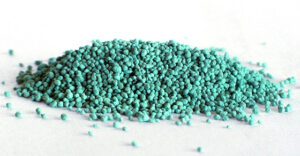

While pelletizing limestone has become common practice for the many advantages it can offer, the process requires careful engineering to ensure a consistently reliable, continuous operation with maximum on-size yield. A number of material characteristics come into play. The Limestone Pelletizing Process The most common …