While the heap leaching process has proven to be an efficient and cost-effective approach to processing low-grade ore sources, efficiency and recovery can be further improved through the addition of an agglomeration drum.

The following covers an introduction to heap leaching, and how agglomeration greatly improves this essential beneficiation process.

A Look at the Heap Leaching Process

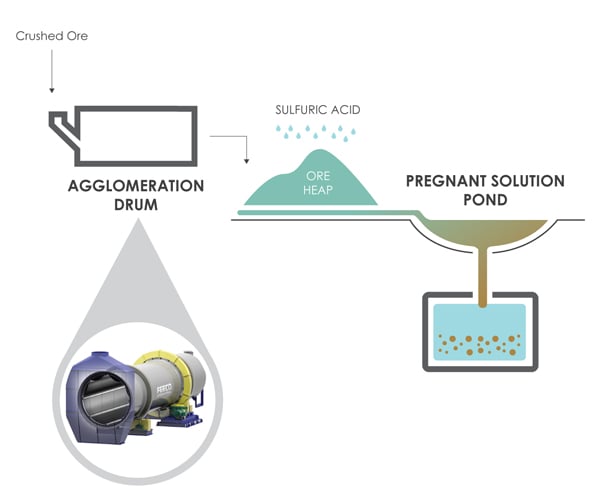

Heap leaching is a hydrometallurgical approach to ore beneficiation in which crushed ore is “heaped,” into a large pile and irrigated with a special solution (referred to as the leachate or lixivant) that reacts with the ore to absorb it.

The irrigated ore pile is allowed to sit for a specified length of time, allowing the leachate to percolate through the ore pile and drain to the bottom of the heap. Once the impregnated solution is collected at the bottom of the heap, it can be purified to extract the valuable target material via solvent extraction electrowinning (SX-EW) or other means.

A simplified flow diagram of the heap leaching process, with agglomeration pre-treatment incorporated

Where is Heap Leaching Used?

Heap leaching has become an essential tool in recovering metals from low-grade ore deposits that cannot otherwise be economically recovered. Historically, heap leaching has been used to recover gold, silver, copper, and uranium.

Recent years have seen zinc, nickel, and platinum group metals being explored as well. In addition to low-grade deposits, heap leaching can be applied to process a wide range of otherwise-challenging metal sources:[1]

- Tailings piles or ponds

- Agglomerated flotation tailings

- Complex run of mine (ROM) ores

- Coarse rejects from semi-autogenous grinding (SAG) circuits

Although heap leaching is most widely recognized for its use in processing low-grade ores, it’s important to note that it can also be applied in settings where minimizing capital cost is paramount for other reasons as well. This might include settings where the grade is high but the deposit is small, or the deposit lies in a politically high-risk area.[1]

When is Agglomeration Necessary in Heap Leaching?

While the heap leaching process has brought significant improvements to mineral recovery in its own right, efficiency can often be substantially improved through the addition of an agglomeration step in which the ore particle size is enlarged through the binding together of fines.

Because the agglomeration process binds up fines, the need for agglomeration is thus largely dependent on the fines content of the ore – the general consensus among experts being that agglomeration is necessary when the amount of fines at –74 μm (200#) exceeds 5%. If the amount of fines exceeds 10-15%, a binder will likely also be needed.[2]

Benefits of Incorporating Agglomeration into the Heap Leaching Process

By incorporating agglomeration into the heap leaching process, mineral processors can gain a number of significant advantages:

Improved Leaching Agent Percolation

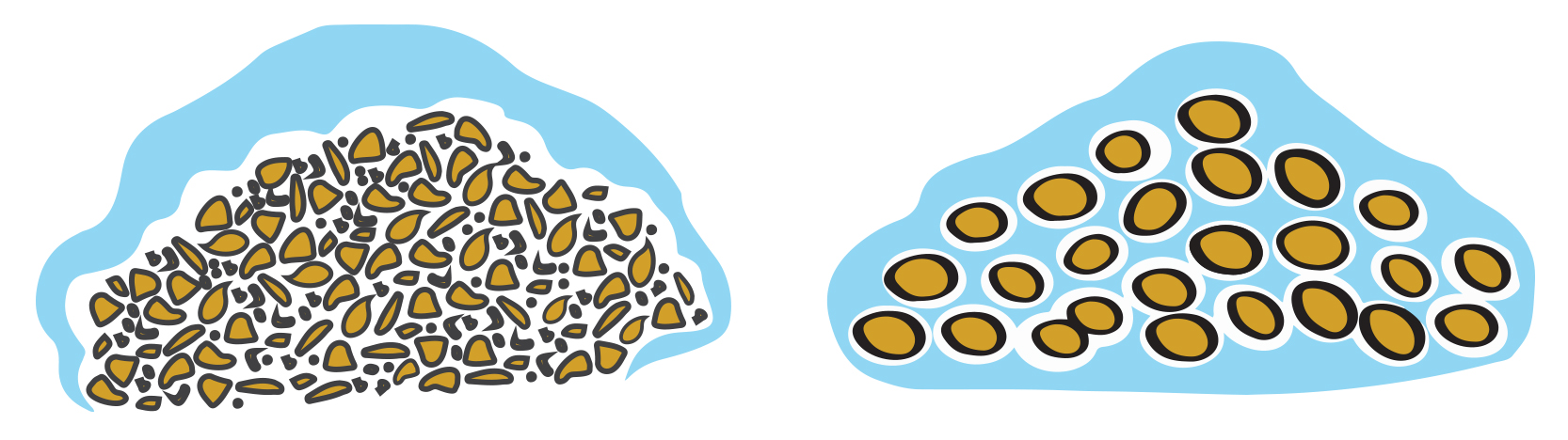

Fine particles are prone to creating blockages in the heap, around which the leachate flows, leaving some areas untouched and slowing down the leaching process. By converting fines into larger, more uniform agglomerates, the leachate can more easily and uniformly flow through the heap, as shown in the illustration below.

Image: At left, non-agglomerated ore fines clog channels, impeding leachate percolation. At right, agglomerated ore fines allow more even and effective percolation of the leachate through the heap.

Enhanced Intra-Particle Structure

Agglomerated fines offer a porous media that promotes liquid retention and mass transfer, which accelerates the leaching reaction.[3]

Greater Heap Leaching Efficiency

By introducing the leachate into the agglomerator, the ore fines and leachate are thoroughly mixed. This creates greater contact between the leachate and ore and allows the reaction to begin prior to the heap.

Further, by producing more uniform particles, mineral processors can avoid the leachate ponding associated with the segregation of differently sized particles, as large particles tend to roll to the base of the heap.[2]

Increased Production

Mineral processors are able to increase heap height, thereby increasing production, because of the more stable structure of an agglomerated heap.[2]

Maximum Value Recovery

The maximum recovery afforded by agglomeration significantly outweighs the initial capital expenditure and allows the operation to be as efficient as possible.

Environmental Benefits

By reducing losses and recovering as much value as possible from the resource, companies can minimize waste and reduce the environmental impact associated with mining operations.

All of these benefits translate to:[2]

- Enhanced Metal Recovery

- Shorter leach cycles

- Additional metal recovery from otherwise-spent sources

- Improved environmental heap closure

In one Arizona silver mine, for example, the incorporation of an agglomeration step increased metal recovery from 37% to 90%, while at the same time dropping the leaching time from 90 days to just seven. Similarly, a gold mine in Nevada saw extraction increase by 60%, with leaching time cut in half.[2]

Agglomeration Drums: The Preferred Approach

While a variety of agglomeration equipment has been explored for use in heap leaching, the industry has come to favor the agglomeration drum.

Also called ore drums, agglomerators, or heap leaching drums, agglomeration drums are based on a rotary drum design: a large, rotating drum tumbles material through its interior, typically in the presence of a liquid and/or binding agent to form granules.

3D Rendering of a FEECO Agglomeration Drum

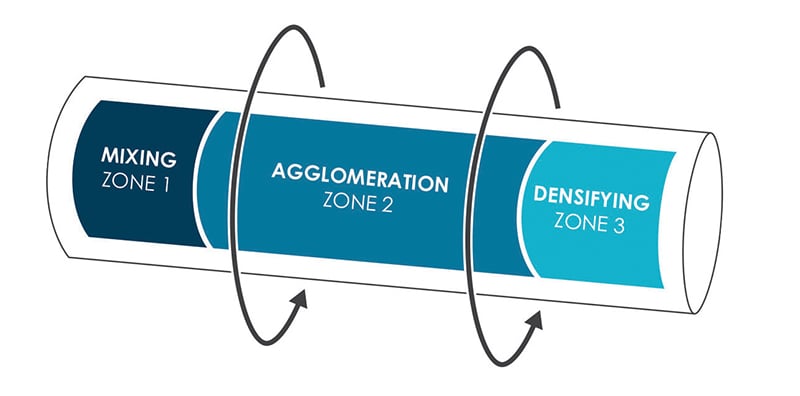

In the case of the heap leaching process, ore fines are tumbled through the drum prior to heaping on the leach pad. Leachate, and if necessary, a binder, are sprayed over the tumbling bed of material at predetermined locations. This promotes the mixture of fines and leachate, while also agglomerating fines into a more uniform particle size distribution. As the material continues to tumble through the drum, granules become more dense.

Operating zones of an agglomeration drum (agglomerator)

The agglomeration drum is the preferred equipment for use in the heap leaching process for a number of reasons:

High Throughput

Agglomerators are high-capacity machines, capable of processing up to 3000+ TPH in a single unit. This high throughput is ideal for the quantities of low-grade ore associated with heap leaching operations. When additional capacity is required, two drums can be placed in parallel.

FEECO Agglomeration drums at a heap leaching operation

Heavy-Duty Construction

Agglomeration drums are extremely robust, offering reliable processing in even the harshest environments.

Thorough Mixing

The tumbling action facilitated by the rotating drum, paired with the internal spray system, promotes optimal mixing of the fines and leachate (with binder, if necessary). The homogeneous mixture ensures intimate contact between the components for maximum recovery.

Interior view of copper tumbling in an agglomeration drum

Customization

Agglomeration drums are also incredibly customizable. From the construction materials to the spray system design, these machines can be tailored for optimal performance based on the specific characteristics of the ore source.

Various add-ons, such as wear liners, trommel screens, tumbling flights, and knockers, can be incorporated to improve functionality and prolong equipment service life.

A rubber liner installed in an agglomeration drum for added protection against abrasion and corrosion

Is Agglomeration Right for Your Process?

While agglomeration can bring significant benefits to a heap leaching operation, the ability to quantify those benefits prior to investment is critical.

For this FEECO offers a pilot-scale rental agglomeration drum, allowing mineral processors to conduct in-house development and produce agglomerated samples for leaching tests.

This provides an invaluable opportunity to reduce risks prior to scale-up.

Conclusion

The heap leaching approach to ore beneficiation is a growing trend in the mining industry, with applicability to an increasing number of metals. The incorporation of an agglomeration step, particularly when carried out in an agglomeration drum, further improves this process through a number of benefits such as shorter leaching cycles and increased metal recovery.

FEECO provides the mining industry’s most reputable agglomeration drums to heap leaching operations around the world. Our custom built rotary drum agglomerators are robust and built for longevity. In fact, some of the world’s largest and most environmentally advanced mining operations rely on FEECO for the best in agglomeration drum technology. In addition to extensive testing capabilities, we offer a comprehensive parts and service program to assist with everything from spare parts to retrofits and rebuilds. For more information, contact us today!

SOURCES:

- Reddy, K. S., & Agarwal, S. (2015). Heap Leaching Technology: Current State, Innovations, and Future Directions – A Review. ResearchGate. https://www.researchgate.net/publication/284274361_Heap_Leaching_Technology-Current_State_Innovations_and_Future_Directions_A_Review

- Dominguez, J., & Rodriguez, E. (2011). Review of Agglomeration Practice and Fundamentals in Heap Leaching. ResearchGate. https://www.researchgate.net/publication/248933800_Review_of_agglomeration_practice_and_fundamentals_in_heap_leaching.

- Chitera, L. M., Chimwani, N., Gumbochuma, S., Madzokerea, T. C., & Bhondayi, C. (2022). Optimization of agglomeration parameters for enhanced gold recovery in cyanidation processes. International Institute of Chemical, Biological & Environmental Engineering. https://iicbe.org/upload/4283C1122205%20J%20new%20new%20new%20final%20formatted.pdf