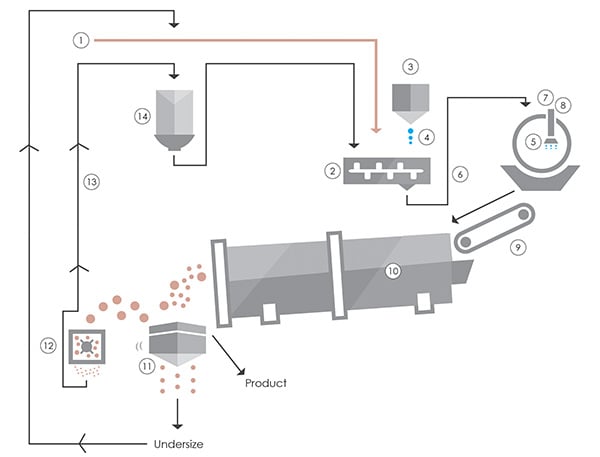

Pelletization is an agglomeration process whereby material fines are “grown” through a tumbling motion in the presence of a liquid binder or water. While all agglomeration processes can be customized to suit the unique needs of the material being processed, in general, it follows these sequential steps:

1) Material fines can be pre-conditioned in a pin or paddle mixer. Not all pelletizing processes use a pre-conditioning step, but those that do see added benefits such as reduced binder use, increased production, and an improved end product.

2) After pre-conditioning, the material moves on to the disc pelletizer. For those that do not pre-condition, this is where the pelletization process begins. Here, material is continually fed to the disc pelletizer and wetted by a liquid binder spray.

The disc’s rotation causes the wetted fines to form small, seed-type particles (nucleation). The seed particles “snowball” by coalescence into larger particles until they reach their desired size and exit the pan. When a pre-conditioning step is used, seed pellets form in the mixer, and are enlarged and further rounded and refined on the disc pelletizer.

3) Finally, a belt conveyor transports the pellets to a rotary dryer if moisture removal is necessary. While reducing the moisture content, the dryer can also polish pellets into their final, hardened form.

Please see the flow diagram below for a visual representation of the pelletization process:

- Raw Feed

- Paddle/Pin Mixer

- Binder Feed

- Spray Rate

- Disc Pelletizer

- Feed Onto Pelletizer

- Binder Feed

- Liquid Spray System

- Transfer Conveyor

- Rotary Dryer

- Vibrating Screen

- Oversize Mill

- Recycle

- Surge Hopper

For more information on pelletization, contact us today!