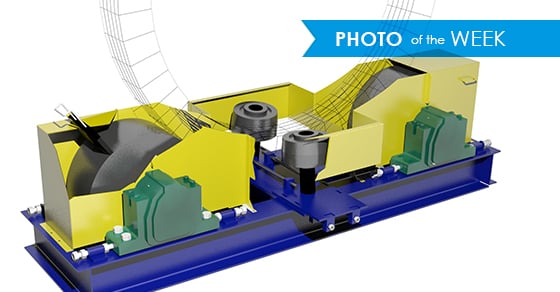

Today’s photo highlights a trunnion wheel and thrust rollers. The 3D image was produced by FEECO’s in-house design team.

Trunnion wheels support the weight of a rotary drum, be it a dryer, cooler, kiln, or granulator. Most importantly, they provide a place for the tire to ride on, acting as a wear piece, since they are more cost-effective to replace than the actual riding ring. In addition, they help the drum to ride true and concentric. The trunnion wheels are mounted in bearings, and the bearings are mounted on a steel framed trunnion base (pictured in blue). The bases are typically mounted on concrete piers.

The thrust rollers, pictured in the middle, ride on the downhill and uphill edges of the tire with little to no contact with the riding ring/tire, helping to keep the drum from drifting. Thrust rollers are mounted about ¼” of tolerance from the tire, and the drum should be aligned to float in between the rollers without riding hard on one or the other.

FEECO has designed and manufactured rotary drums for over 60 years. For more information on our custom equipment, contact us today!