Finding a rotary kiln manufacturer that can meet the specific needs of the project at hand can be a challenge. What follows is a guide covering some of the key factors to consider.

Critical Qualities in a Rotary Kiln Manufacturer

1. Process Development Capabilities

Finding a manufacturer that can work with you to develop a process that meets your specific process and product goals is critical. The growing number of applications in which rotary kilns are employed, combined with unique material compositions and behavior, as well as diverse process goals, make testing an essential part of developing a successful operation.

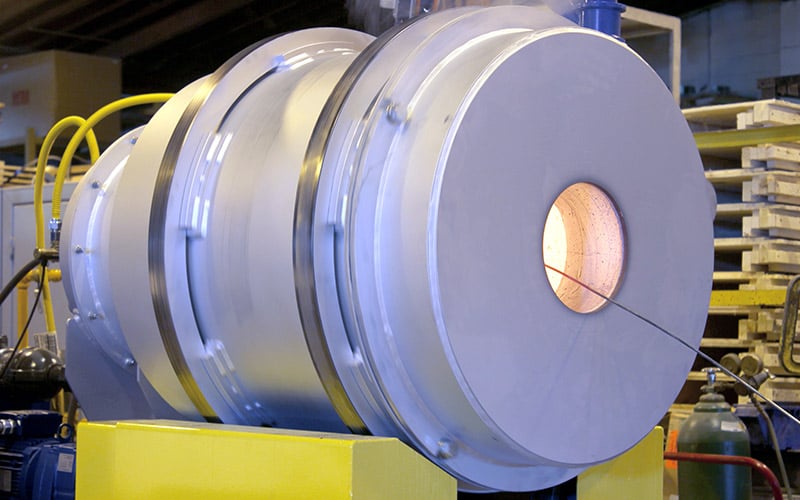

It is for these reasons that it is important to find a rotary kiln manufacturer that has the testing capabilities to work through these product and process development stages. Ideally, the manufacturer will have representative batch- and pilot-scale testing units available to first assess initial feasibility, and then gather and analyze the process data necessary to produce the desired results and build a commercial-scale kiln.

Direct-fired batch kiln used for testing in the FEECO Innovation Center

The ability to test the process throughout development provides an additional benefit as well; OEMs with these capabilities will often provide a process guarantee with their equipment, reducing the amount of risk the buyer must undertake.

In some cases, depending on the manufacturer and their engineering expertise, process guarantees may also be available without testing as well. This may be the case if the manufacturer has advanced engineering experience, allowing them to accurately predict process performance based on in-depth modeling.

2. Advanced Thermal Processing Knowledge

Rotary kilns are powerful systems, requiring a precise balance of several dynamics to produce the desired product results. Selecting a rotary kiln manufacturer that is well-versed in advanced thermal processing knowledge will ensure the best results. It is especially valuable if the manufacturer can draw on past experience with the application at hand.

Furthermore, without the proper engineering and design, rotary kilns do have the potential to be dangerous. Confidence that the manufacturer will be able to supply equipment that will not only operate efficiently for years, but will also remain safe for continued production is a must.

Direct-Fired FEECO Rotary Kilns

3. Proven Rotary Kiln Design

Be sure to select a rotary kiln manufacturer with proven equipment. The difference between proven and unproven design may not be obvious at first, but there are things you can look for to help validate manufacturer claims. One aspect to look for is a service division; this usually means that the manufacturer’s equipment has been around long enough to require replacements of old, worn-out components. Additionally, asking for case studies, project profiles, or reference lists can give an idea of projects they’ve been successful with, as well as the types of companies they’ve worked with previously.

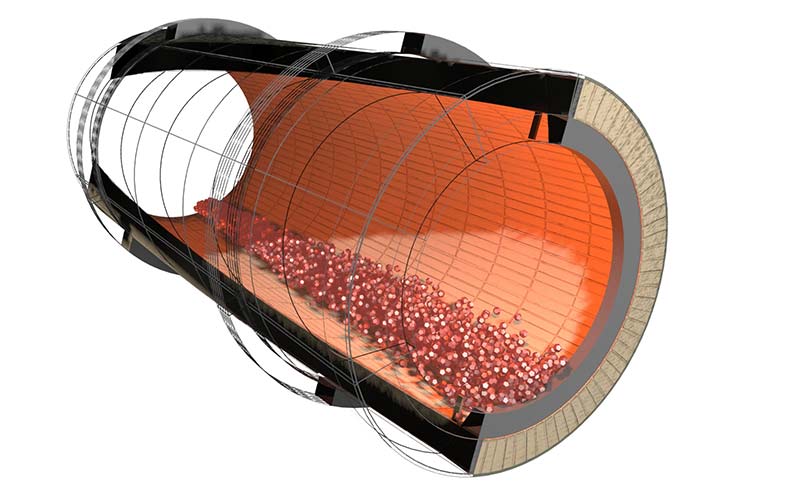

3D Rendering of a Rotary Kiln with a dam designed to increase retention time

4. Complete System Supply

Rotary kilns are not a stand-alone thermal processing device; they require a variety of supporting equipment to operate safely and within regulation. Additional equipment typically includes exhaust gas handling, a burner and potentially a combustion chamber, NOx requirements, bulk material handling equipment for feeding and offtake, and in some cases, product cooling. A pre-heater is also necessary in some settings to bring the material up to temperature in preparation of the kiln.

In choosing a rotary kiln manufacturer, look for one that can offer complete system supply. This will not only reduce the amount of headaches in sourcing and integrating the various components, but it will also ensure accountability of the entire system on the part of the OEM.

FEECO Indirect Rotary Kiln

5. High-Quality Fabrication

Quality materials and fabrication techniques are crucial for a rotary kiln that will stand the test of time. As previously mentioned, these are very powerful systems that require meticulous engineering and high-quality fabrication. Any shortcuts taken at this stage will resonate throughout the life of the kiln, causing unnecessary downtime, process inefficiencies, and likely costly repairs.

FEECO welders working on a rotary kiln in fabrication

Ask the manufacturer to provide their quality control practices and standards, as well as certifications in welding and engineering.

Be sure to inquire about whether or not the rotary kiln manufacturer manufactures the equipment themselves, or if they utilize a third-party fabricator. Utilizing an external vendor for fabrication often makes quality specifications difficult to control, unless scrupulously managed.

6. Parts & Service Support

When choosing your rotary kiln manufacturer, it is important that the company provides the necessary support for the purchased equipment in a variety of areas including:

- Installation & Start-up

- Training (Operation and routine maintenance)

- Spare Parts

A rotary kiln manufacturer should be experienced in servicing their equipment, offering a variety of services to keep your rotary kiln operating efficiently for years to come. The ability to have the original equipment manufacturer perform these services offers an advantage over kiln service companies; the original equipment manufacturer is most familiar with the operation of the kiln and how it should best be maintained.

A FEECO Customer Service Engineer inspects the interior of a rotary kiln

Conclusion

To ensure maximum efficiency and potential from your rotary kiln investment, select a company that will provide a high-quality rotary kiln. Thermal processing knowledge, concept testing, innovative design, and high-quality manufacturing all play a vital role in the production of a premium piece of equipment.

FEECO is a leader in custom thermal processing systems. We can help develop a process around the unique process goals of a project in our in-house batch and pilot testing facility, The FEECO Innovation Center. We then use the gathered process data to scale up the process to full-scale production, and manufacture the equipment needed to get the job done. We also offer a highly skilled service department to assist in everything from start-up and install, to routine maintenance and repairs. For more information on our rotary kilns, contact us today!