In the copper production via smelting process, pugmill mixers are used for mixing and conditioning.

Pug mills are highly proficient at combining both solid and liquid feeds into a homogenous mixture, and are therefore an ideal mixing device in the smelting process.

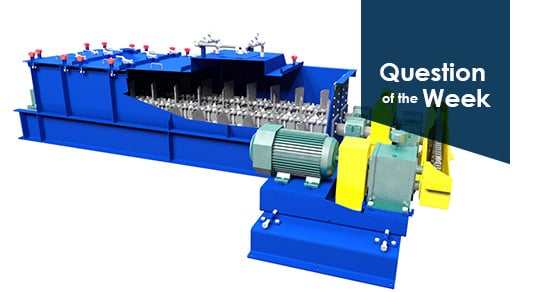

Numerous components are combined prior to the smelting furnace. This most often includes the copper concentrate, flux, reverts, matte recycle, and dust recycle. The materials are fed into the paddle mixer along with a water, and as the shafts rotate, the materials are mixed into a uniform blend.

This step also conditions the material for the smelter. The addition of the water forms de-dusted agglomerates as the copper concentrate mixture moves through the pugmill mixer. If the material is not conditioned, it would be lost in the form of dust during transportation to the smelter.

For more in-depth information, read our blog post The Role of Pug Mills in Processing Copper Concentrates