The FEECO Innovation Center offers a variety of agglomeration test work to help develop new products, optimize current processes and more.

The following highlights our agglomeration testing capabilities:

NON-PRESSURE

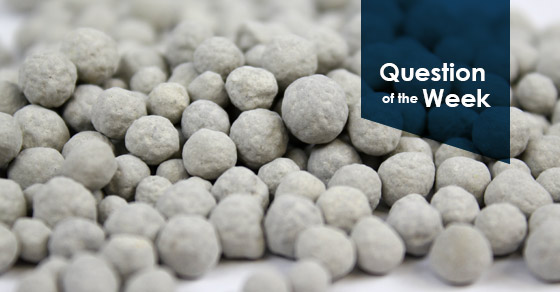

Pelletizing (rotary drum or disc pelletizer): A wet process where material fines are rolled into pellet form with the assistance of a binding agent.

Conditioning: the mixing of material fines with a binding agent to reduce dust, and transform the material into a usable form.

Mixing: the act of thoroughly blending material and binding agent, be it for pre-conditioning, or as a stand-alone agglomeration processing unit.

Coating: used to perform particle coating applications to improve product characteristics.

Micro-pelletizing: a wet process where material fines are mixed with a binder to form small agglomerates, or to prepare the material for pelletizing.

PRESSURE

Briquetting: A dry process which uses pressure to form pillow-shaped briquettes from material fines.

Compaction: Also a dry process, which presses material fines into a sheet-form. The sheet is then broken up into jagged granules.

For more information on agglomerating your material at FEECO, contact us today!