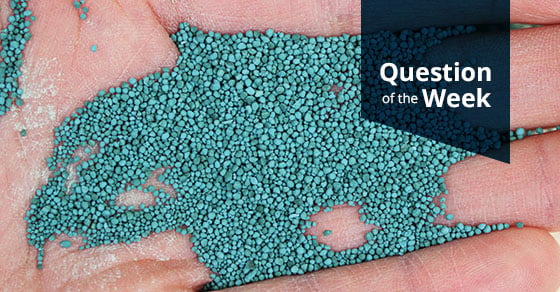

Micro-pelletizing is the process of agglomerating material fines into small pellets. This differs from traditional pelletizing, in that it produces much smaller pellets, typically around 20-60 mesh.

Pin mixers are the equipment of choice when it comes to micro-pelletizing; they can be used as a stand-alone agglomeration device to produce micro-pellets in a continuous process setting. In fact, they are the industry standard when it comes to micro-pelletizing.

In a typical micro-pelletizing setup, raw feed and binder are fed into the pin mixer at a specified rate. The materials are thoroughly mixed, and begin to agglomerate. Micro-pellets then form as the mixture moves down the length of the pin mixer.

After processing in the pin mixer, the material could then be fed onto a disc pelletizer to further grow and/or round the pellets. However, when only conditioning or small pellets are needed, a pin mixer alone can provide satisfactory results. A rotary dryer can also be used to reduce the pellet’s moisture content.

Micro-pelletizing is a valuable way to transform powdered materials into a more easily handled, transported, and applied product. From pigments and dyestuffs, to carbon black and fly ash, nearly any material in a powder form can benefit from the process.

To see if micro-pelletizing can benefit your material, contact us today!