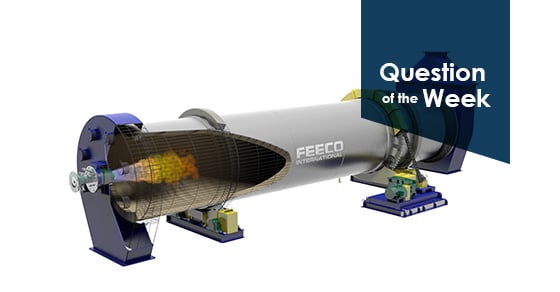

Bed disturbers are used in both direct and indirect-fired rotary kilns to promote uniform heating of the material.

The bed of material should roll, not slide, throughout the kiln in order to expose fresh material to the process. This rolling action allows for even heat distribution throughout the bed of material. For this reason, a bed disturber can be employed to prevent the bed from sliding, and to encourage uniform heating.

A bed disturber is essentially anything affixed to the interior of the kiln to help mix the bed of material. Ideally, the bed of material will tumble and turn over, and thus minimize dead spots or temperature variations in the kiln.

Indirect rotary kilns commonly utilize a metal bar as their bed disturber. The bar is affixed to the kiln’s interior, and spans the length of the kiln. In this situation, material will push up against the bar, build up, and roll over the bar, so the material at the top of the bed is now redistributed to the bottom of the bed.

Flights, or material lifers, are another bed disturber option, and are ideal for kilns with temperature gradations.

A bed disturber should be customized to increase the efficiency of the kiln. To learn more about rotary kilns, download our ebook, or contact a FEECO expert today!