Rotary kilns can be configured to fit nearly any process need, with a variety of customizations available to engineer an optimal processing solution. One customization that helps to promote efficiency in an indirect kiln is the bed disturber.

Why use a Bed Disturber

Indirect rotary kilns create heat transfer by conduction through the shell of the rotary kiln, rather than by means of contact with a process gas. Because all of this heat transfer is occurring through the shell, it is essential that the bed rolls rather than slides against the shell in order to expose fresh material and promote even heat distribution throughout the bed.

Bed disturbers may also be used in a direct-fired kiln for the same reason; the bed disturber helps to prevent the bed from sliding and promotes more uniform heating.

How a Bed Disturber Works

A bed disturber is essentially anything affixed to the inside of the rotary kiln that helps to mix the bed of material. Ideally, the bed should tumble, turning over and minimizing dead spots, or temperature variations within the bed.

Unfortunately, not all materials tumble well, which results in a slipping bed with poor mixing and large temperature variation. Bed disturbers can be attached to the interior of the rotary kiln in order to disturb the bed and turn it over.

The Bar Bed Disturber

A common bed disturber used in an indirectly heated kiln is a bar that runs the length of the interior of the kiln. Material pushes up against the bar, building up and rolling over it, so material that was on the top of the bed now gets redistributed to the bottom of the bed. The disadvantage to using a bar bed disturber is that they can sometimes bend and break with the thermal stresses of the rotary kiln.

A rotary kiln naturally has gradients of temperature—usually cooler on the ends of the rotary kiln, and hotter in the middle. This gradation in temperature causes differential thermal expansion on the rotary kiln shell. As a result, the bar, welded to the shell, is pulled in different directions, which can cause the weld to break. When this kind of thermal expansion is at work, it is usually best to look at alternative bed disturbers.

Flights as Bed Disturbers

Flights, or lifters can also be used as a bed disturber. In this case, flights are welded with one weld point each to the inside of the rotary kiln. This method of disturbing the bed is designed to accept the different thermal expansion stressors, making it ideal for drums with temperature gradations.

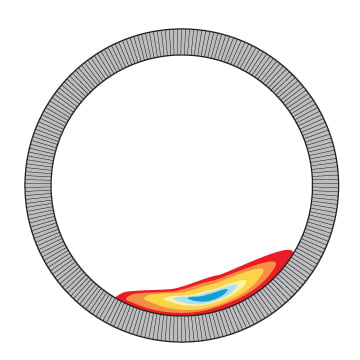

FIGURE 1. In a bed that just slips along the interior of the rotary kiln, the inner part of the bed never really gets exposed to the rotary kiln shell, creating major temperature discrepancies. |

|

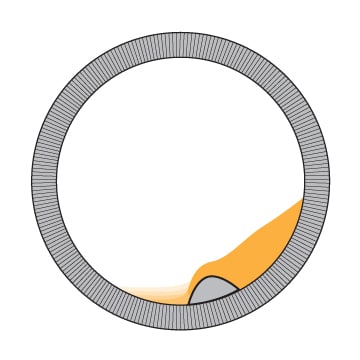

FIGURE 2. Fixed to the interior of the rotary kiln, a bed disturber turns over the bed of material by creating a place for the material to build up and tumble over, redistributing what was on top to the bottom, and vice versa. |

Conclusion

Bed disturbers offer an excellent solution to maximizing heat transfer efficiency in an indirect kiln, helping to turn over the bed and redistribute the material. The bed disturber is just one customization available to optimize the design of a rotary kiln for superior performance.

FEECO is a leader in advanced thermal processing, offering batch- and pilot-scale testing capabilities, engineering, and manufacturing of custom rotary kilns to suit the exact needs of a project. For more information on our custom rotary kilns, contact us today!