Rotary drums are central to countless industrial processes, and whether drying, heating, cooling, or granulating, their performance depends on precise alignment and structural integrity. One often-overlooked, yet critical, rotary drum maintenance task for ensuring both is tire reshimming.

A small adjustment with a big impact, proper reshimming helps maintain drum alignment, minimize wear, and prevent costly equipment failures. If left unaddressed, even small gaps from improper shimming can trigger a series of problems that compromise both the performance and lifespan of a drum.

The Function of Drum Tires and the Role of Tire Shims on a Floating Block Tire Mounting Design

Drum tires, or riding rings, serve two primary functions:

- Support the weight of the rotating shell and its contents.

- Provide a surface on which the drum rides as it rotates over trunnion rollers.

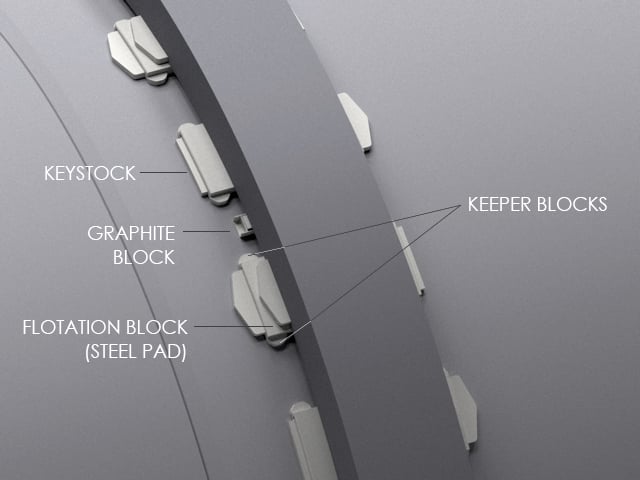

FEECO rotary drums utilize a floating tire assembly. Rather than being rigidly affixed, tires “float” on the shell, resting on flotation blocks (steel pads) known as filler bars held in place with keeper blocks.

Compared to historical approaches, this floating design better accommodates the inherent “flex” (ovality) that occurs during drum rotation. It also prevents distortion of the drum due to tire restriction when thermal expansion occurs.

Since the tire and drum rotate asynchronously, this design relies on a snug fit of the tire against flotation blocks when running at normal operating temperatures. When these filler bars become worn, tire creep can occur.

Tire Creep

Tire creep refers to the circumferential movement of the tire around the drum (over the filler bars) due to the different-size circles spinning together. In other words, because the tire is “floating” and not rigidly fixed, movement could occur if the tire is not held in place with filler bars.

Over time, however, filler bars may degrade, corrode, or compress, requiring reshimming to restore the proper interface between filler bars and tire, providing a stable interface, while still allowing for any natural flex and thermal expansion.

Shims—thin metal plates inserted between the shell and tire mounting block (filler bar)—are used to fill that gap and maintain a proper interface, thus preventing tire creep.

Why is Tire Creep a Problem?

Tire creep works against the drum’s thrust forces, causing the tire to wear away keeper blocks. If allowed to persist, this can result in axial movement of the tire on the drum, sometimes referred to as tire migration. This usually happens gradually depending on operating conditions, skewing procedures, thermal expansion, and asymmetric loading.

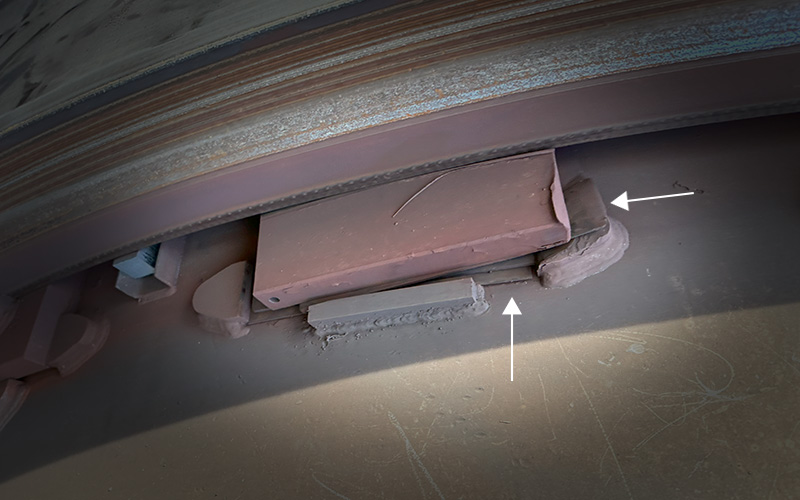

Axial movement of the tire is evident by the gap between the tire and side keeper block shown in this photo.

Axial movement of the tire on the drum affects the distribution of the drum’s weight across trunnions; if it causes the tire to overhang the trunnion, the resulting forces in the tire/trunnion increase. This uneven loading accelerates wear on support components and can lead to misalignment of the entire drum. The tire may also collide with thrust rollers or stops, putting unnecessary stress on the tire and mounting system.

The following symptoms may indicate that axial movement is occurring:

- The tire may appear slightly offset toward one end of the drum.

- Shim packs may be visibly missing or crushed on one side.

- Friction marks or scoring may be visible on the shell beneath the tire.

Why Tire Reshimming is Critical

In addition to tire migration, failing to maintain proper shimming can quickly escalate into a host of other problems as well, including:

- Trunnion and roller wear – Uneven tire support results in imbalanced loading, which accelerates wear on support components and bearings.

- Vibration and noise – Misalignment introduced by tire slippage or uneven shimming causes drum instability, thumping, and excessive vibration.

- Seal failures – When the drum becomes misaligned, seals at the feed or discharge end can become compromised, allowing air ingress.

Increased maintenance costs – Over time, small shimming issues can escalate into costly realignment projects, tire remounting, or even shell replacement.

In this case, tire creep has caused a shim to “walk” up onto the side keeper. This will ultimately put a localized stress point on the tire, which, in severe cases, could crack the tire. Remaining shims in proper placement can also be seen.

Reshimming addresses these issues proactively, maintaining drum integrity and optimizing operational efficiency.

When to Reshim

Tire creep is easily measured by drawing a continuous chalk line from the tire onto the drum. If after rotation the line no longer matches up, tire creep is present. Creep should be kept to a minimum – ideally zero, though minimal creep is permissible.

When the creep is greater than ½” per revolution (under normal operating conditions and temperature), FEECO recommends preparing for a reshim by ordering shim kits. When the creep is ¾” per revolution, reshimming should be performed at the next available outage.

Excessive tire creep is indicated in this image with the once-adjoining chalk lines that have separated after rotation.

In addition to measuring tire creep, look for signs of shim wear. These may be subtle at first, which is why routine inspections are so critical. Some of the most common indicators of shim wear and potential failure include:

- Visible Gaps Between the Tire and the Filler Bar: This is the most direct visual sign that the tire is no longer tightly seated.

- Uneven or Accelerated Wear on Tires or Trunnions: If one side is wearing faster than the other, it may point to uneven support from missing or compressed shims.

- Abnormal Movement During Operation: Axial movement (side-to-side) or radial movement (up-and-down) of the tire indicates instability and loss of proper seating.

- Audible Thumping or Vibrations: Shimming issues can manifest as new or irregular noises, especially when the tire slips slightly or shifts position during rotation.

Previous Tire Remounts or Adjustments: Drums that have been remounted without reshimming or proper adjustment may require follow-up reshimming to maintain stability.

The Tire Reshimming Process

Tire reshimming can often be completed with minimal disruption to operations. While each project may vary slightly, the general procedures is carried out as follows:

1. Assessment & Measurement

A FEECO customer service engineer begins by inspecting the tire-to-shell interface and measuring any gaps or movement. Specialized tools may be used to assess roundness (ovality), tire float, and overall alignment.

2. Shim Removal

Any remaining shims are removed to eliminate uneven or ineffective contact points. This allows for a clean, accurate re-shim.

3. Surface Cleaning

Both the inside of the tire (bore) and the outer shell surface are cleaned to remove built-up scale, rust, and debris. Clean contact surfaces are critical to ensuring uniform load transfer and proper shim seating.

4. Shim Selection & Installation

New shims—typically stainless steel or other corrosion-resistant metals—are inserted between the filler bar and shell in specific locations and thicknesses, based on the drum’s dimensions, weight distribution, and thermal behavior. Shim placement is done incrementally and symmetrically to avoid imbalance.

5. Final Alignment & Verification

Technicians verify tire float, check for uniform support, and ensure the drum remains within acceptable alignment tolerances.

Important Considerations in Reshimming

Several factors must be considered to achieve proper reshimming:

Thermal Expansion Gaps

Shimming must allow for thermal expansion of the drum shell. Over-shimming can result in binding, which introduces its own stress points.

Shim Materials and Thickness

Shim choice depends on operating conditions. Stainless steel is preferred for high-temperature or corrosive environments. The shim stack may include multiple plates of varying thickness to fine-tune fit.

Repeat Frequency

For most drum applications, FEECO recommends reshimming every three to seven years. Once the filler bars wear too much, and more shims can no longer be added, a tire remount should be planned.

A tire remount involves the installation of entirely new filler bars and keepers. When reshimming becomes less effective or more frequent, it’s often a sign that the tire has shifted significantly or is no longer seated properly. In these cases, a remount is required to:

- Realign the tire concentrically with the shell

- Restore even load distribution

- Prevent long-term shell distortion or tire damage

Systemic Wear

If reshimming is required repeatedly, it may point to larger issues such as trunnion misalignment, foundation movement, or tire warping. For this reason it is helpful to have a collaborative relationship with an experienced service provider, as they are most familiar with the drum and what might be considered abnormal wear.

Reshimming as Preventive Maintenance

Rather than waiting for damage to appear, reshimming should be treated as a preventive measure in any rotary drum maintenance program.

Reshimming offers a low-cost, high-impact way to:

- Maintain drum alignment

- Minimize wear on tires and trunnions

- Extend equipment life

- Improve operational efficiency

- Prevent unplanned downtime and emergency repairs

FEECO’s Field Services for Tire Reshimming

FEECO’s experienced field service engineers bring decades of rotary drum expertise to every job site. We offer complete on-site reshimming services as part of our broader drum maintenance capabilities, including:

- Visual and mechanical inspections

- Drum alignment

- Tire remounting and replacement

- Tire and trunnion grinding (resurfacing) and adjustment

- Shell repairs and engineering support

- Parts provision

Conclusion

Proper tire shimming is a critical aspect of preventative maintenance for all types of rotary drums. Whether you’re experiencing symptoms of a shifting tire or simply want to keep your equipment running at peak performance, FEECO can assess and correct shimming issues before they escalate. To schedule an inspection or learn more about our reshimming and rotary drum maintenance services, contact us today!