Catalyst regeneration via thermal desorption has emerged as a solution for industries grappling with spent catalysts, which pose liability risks and waste management challenges. As processors seek to lower operating costs and minimize their environmental footprint, many are turning to catalyst regeneration through this thermal treatment.

Praised for its ability to burn off volatile components and refresh catalytic activity, thermal desorption is becoming particularly common in the hydroprocessing and petrochemical industries where spent catalyst disposal is subject to strict regulation. A recent market analysis estimated that the catalyst regeneration market will grow at a CAGR of 4.3% between 2023 and 2030.[1]

About Thermal Desorption

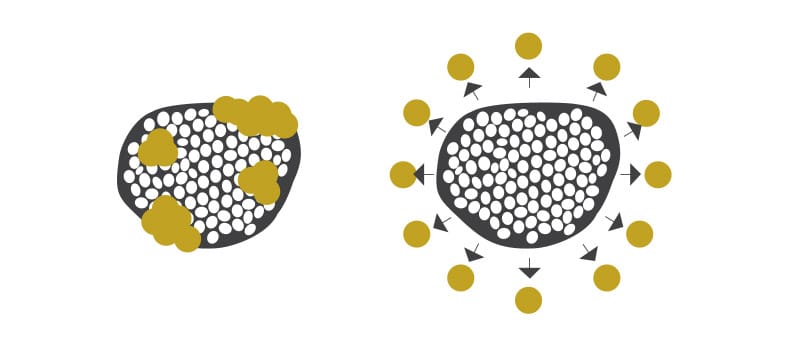

Thermal desorption, sometimes also referred to as spent catalyst drying, is a controlled, high-temperature treatment used to drive off volatile components impeding catalytic activity – in this case any material that has accrued in pore spaces where catalytic activity occurs. In the petrochemical industry, for instance, these materials might include hydrocarbons, metals, coke, and more.

All catalysts lose their catalytic activity over time, gradually filling up with deposited material through continued use. The length of time this takes is highly variable and dependent on the process and catalyst in use, taking anywhere from seconds to years.

Thermal desorption has proven to be an effective technique in reactivating these spent catalysts for reuse.

Why Catalyst Regeneration?

Spent catalysts represent several problems depending on the industry in which they are employed. The ability to regenerate this stream of industrial waste would not only offer significant cost savings to the processor, but could also bring some hard-hitting environmental benefits.

Reduced Need to Purchase New Catalysts

Catalysts are engineered materials. And while their cost varies, they typically represent a substantial expense for most operations, making the need to regularly replace them incredibly costly. If processors were able to reuse their catalysts, they could significantly reduce overall operating costs.

Further, the growing use of heavier feedstocks in the oil and gas industry has resulted in catalysts becoming deactivated more quickly, requiring more frequent replacement. This has further motivated the desire to reuse catalysts.

Reduced Waste Management Costs & Liability Risks

Catalyst disposal requirements vary based on the type of catalyst and the application in which they are employed. As a substantial waste stream, however, spent catalysts can incur hefty waste management costs. They are also a long-term liability for processors when they are sent to landfill, as they pose environmental risks.

This is particularly true of catalysts used in oil refining operations, as they are considered hazardous, requiring highly regulated, special disposal practices. Through thermal desorption, however, these materials can be categorized as “delisted” by the EPA, meaning they are no longer governed by such hazardous waste restrictions.

Ability to Operate More Sustainably

Catalysts have been a major contributor to making industry more sustainable. Ironically, however, they are also a large source of industrial waste themselves.

The environmental risks associated with spent catalysts have put processors under a narrowing spotlight, and as the push for a more circular economy strengthens, sustainably managing this waste is a growing objective.

In addition to helping processors operate more sustainably, the beneficial reuse of spent catalysts has a number of larger environmental implications; the ability to reuse catalysts would significantly reduce new catalyst production. This would cut down on both the associated energy and raw material use.

The Thermal Desorption Regeneration Process

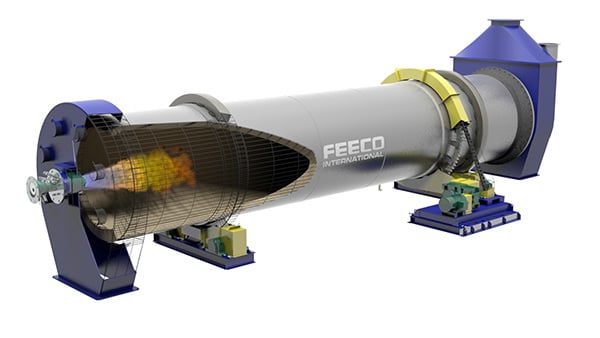

Thermal desorption is carried out in a rotary kiln, sometimes called a desorber for its ability to desorb adsorbed components.

The parameters of regeneration vary significantly depending on the unique physical and chemical makeup of the spent catalyst. As these parameters determine kiln design, the kilns used vary greatly in size and design as well. They may be of the direct or indirect configuration, referring to the mode of heating the material.

How Thermal Desorption Kilns Work

Material is fed into the rotating kiln. In a direct-fired configuration, the spent catalyst and products of combustion are in direct contact. In an indirect-fired kiln, the rotating drum is externally heated and sealed off from the actual processing atmosphere, and material is heated through contact with the drum shell.

In both configurations, the spent catalyst is heated to a predetermined temperature for a specified amount of time, during which the target components will volatilize and be carried out of the kiln, leaving only the catalyst behind.

Thermal desorption volatilizes the components that block active sites on the catalyst, allowing the catalyst to be reused.

The volatilized components go through an exhaust gas treatment system and the catalyst is discharged from the kiln. Depending on subsequent handling, the catalyst temperature may be reduced in a rotary cooler prior to further handling.

It’s important to note that thermal desorption is not always an option; catalysts that have undergone permanent changes in structure or that have been severely contaminated may not be capable of regeneration.

Further, regeneration does note negate the eventual need for replacement; a catalyst can only be regenerated so many times before catalytic activity falls below the acceptable level.[2]

Evaluating Spent Catalyst Regeneration Through Testing

Because spent catalysts exhibit such wide variation, the extent to which regeneration via thermal desorption is effective (if at all) is typically determined through testing.

Thermal desorption testing such as that conducted in the FEECO Innovation Center, is carried out using batch- and pilot-scale test kilns. This allows processors to assess regeneration on a small scale while gathering the data necessary for scale-up.

Numerous process variables are manipulated during testing to determine the best scenario for maximum regeneration. This includes retention (residence) time, temperature profiles, kiln slope and speed, and more.

Conclusion

Spent catalyst regeneration through thermal desorption offers catalyst users, and particularly those in the petrochemical and hydroprocessing industries, a more sustainable approach to waste management. Through thermal desorption, processors can increase the life span of their catalysts, significantly reducing waste management and new catalyst costs.

FEECO is a leading provider of custom rotary kilns for thermal desorption, calcination, and other specialized high-temperature treatments used in catalyst manufacturing and regeneration. Testing is available through batch and pilot kilns in our Innovation Center, with the data gathered through testing used in the design of commercial-scale equipment uniquely suited to the process. For more information on our custom rotary kilns or kiln testing, contact us today!

SOURCES:

- Research and Markets. (2024). (rep.). Catalyst Regeneration – Global Strategic Business Report. Retrieved October 7, 2024, from https://www.researchandmarkets.com/reports/5029792/catalyst-regeneration-global-strategic?utm_source=GNE&utm_medium=PressRelease&utm_code=jckrgp&utm_campaign=1956428+-+Global+Catalyst+Regeneration+Strategic+Industry+Report+2023-2030+-+Rise+in+Consumption+of+Petroleum+Products+Elevates+Demand+for+Petroleum+Refining+Catalysts+and+Catalyst+Regeneration+Technologies&utm_exec=chdomspi.

- Marafi, M., Stanislaus, A., & Furimsky, E. (2010). Handbook of spent hydroprocessing catalysts: Regeneration, rejuvenation and reclamation. Elsevier. October 7, 2024, https://www.google.com/books/edition/Handbook_of_Spent_Hydroprocessing_Cataly/uh1OpCwwAsoC?hl=en&gbpv=1&dq=catalyst+regeneration&printsec=frontcover