Smelting is a pyrometallurgical process that uses thermal processing techniques to purify copper through chemical reactions. And while most focus is given to the furnaces involved in this process, one piece of equipment has not only helped to increase the efficiency of copper smelting, but has become an integral component to the process: the pugmill mixer.

The pugmill mixer has improved upon the smelting process so much so, in fact, that companies are likely to either purchase two mixers (one as a spare), or have a bypass system designed specifically in the event that the mixer needs maintenance.

How the Pugmill Mixer is Used With Copper Concentrates

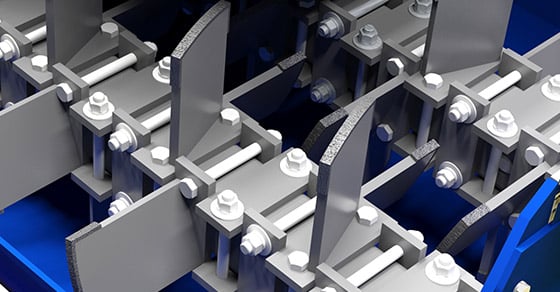

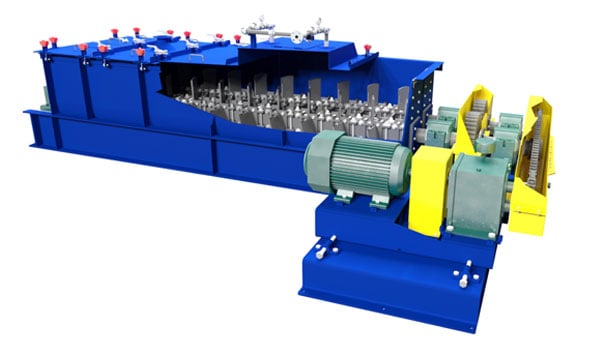

The pugmill mixer is an industrial, horizontal mixer utilized throughout the mining industry for a variety of applications. The heavy-duty build of the pugmill mixer, combined with the kneading and folding over motion created by dual rotating shafts affixed with pitched paddles, makes it highly effective for processing difficult materials in demanding settings.

In copper production via smelting, the pugmill mixer serves two main purposes: mixing and conditioning.

Mixing

The pugmill mixer is adept at combining solid and liquid feeds into a homogeneous mixture, making it ideal for use as a mixing device in the smelting process.

Several components are combined prior to the smelting furnace. This will likely include the copper concentrate, flux, reverts, matte recycle, and dust recycle.

The various materials are fed into the mixer, along with water via a spray system. As the shafts rotate in the u-shaped trough, the materials are homogeneously mixed into a uniform mixture.

Conditioning & Dust Suppression:

This step also serves to condition the material for the smelter. The addition of the water forms de-dusted agglomerates as the copper concentrate mixture moves through the pugmill mixer.

Dust not only creates a hazardous working environment, but it also reduces operational efficiency. If not conditioned, material would be lost in the form of dust during transit to the smelter. Additionally, dusty materials reduce the efficiency of the smelting process, as they become entrained in the process gas and exit the system, resulting in the need to process more material as recycle, further decreasing efficiency.

Copper Concentrate Pugmill Mixer Design

While pugmill mixers are inherently robust, the processing of copper can be especially demanding, requiring additional considerations and modifications during the design stages. Due to the abrasive nature of copper concentrates and the accompanying materials, pugmill mixers must be built to withstand harsh processing conditions.

Paddles, for example, are often lined with an abrasion-resistant material such as a ceramic, in order to prolong paddle life. Stainless steel is also commonly used in pugmill mixer construction in order to combat the corrosive nature of copper concentrates.

3D Illustration of a FEECO Pugmill Mixer

Click the image below to view the infographic on copper processing >>

Conclusion

Copper is a valuable metal for its many uses in industrial civilization. The smelting process has been the primary means of copper production for generations. The use of a pugmill mixer to mix and condition copper concentrates prior to smelting helps to improve overall efficiency through uniform processing and a reduction in dust, making it an invaluable tool in the copper processing industry.

When it comes to custom, heavy-duty pugmill mixers for processing copper concentrates, the mining industry has come to rely on FEECO for our innovative engineering and superior manufacturing. Our decades of knowledge and experience in processing copper gives us the expertise needed to provide you with a solution that fits your exact needs. For more information, contact us today!