The ongoing push to implement more sustainable practices continues to be at the forefront of every aspect of industrial processing. In this effort, high-temperature kilns, or rotary kilns, are turning out to be pivotal equipment in the effort to bring about positive change, both directly and indirectly.

Here, we’ll examine some of the many and diverse ways in which this flexible type of thermal processing equipment is being applied to improve the sustainability of the world around us.

About High-Temperature Kilns

Like other types of industrial furnaces, high-temperature kilns employ carefully controlled thermal processing environments to reach processing and product quality objectives, typically to accomplish complex chemical reactions or phase changes.

Processing takes place inside a rotary drum, where a predetermined temperature profile and retention time facilitate the desired reaction(s). Temperature profiles and retention times, as well as other process variables (percent fill, drum rotation speed, slope, and more) are typically determined through a combination of calculations, process development testing, and in some cases, prior experience.

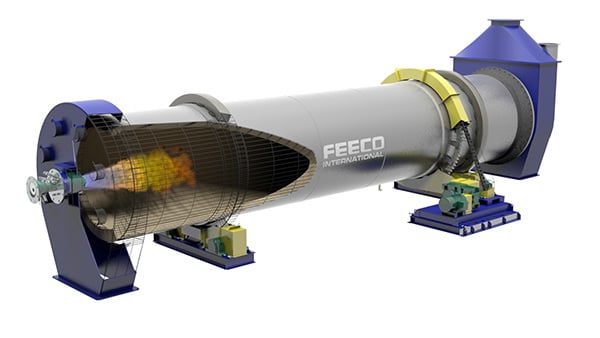

Material is processed either by direct contact with products of combustion (in this case referred to as a direct-fired kiln), or by contact with the externally heated drum shell (referred to as an indirect-fired kiln).

Direct-fired kilns are often refractory lined to protect the drum shell. A burner fueled by natural gas, propane, diesel, or other common fuel type is mounted to the inlet or discharge end housing depending on whether the unit requires a co-current or counter-current air flow design (direct-fired only).

Indirect kilns are externally heated using a heat shroud and multi-burner setup. Because of this, it is possible to create the desired temperature profiles along the length of the kiln through multi-zone arrangements.

Indirect kilns often employ bed disturbers to rotate the bed and ensure even heat distribution. Other internals for improving efficiency and performance are also available for both direct and indirect designs.

Both configurations can offer highly controlled processing environments suitable to just about any process. In both settings, however, kilns must be built according to the unique specifications of the process and material goals in order to achieve optimal results as efficiently as possible.

3D Model of a direct-fired rotary kiln

Novel High-Temperature Kiln Applications

Because they are simply vessels facilitating chemical and physical reactions, rotary kiln systems are capable of carrying out a number of thermal processes, lending them to an array of applications and objectives around hundreds of materials. They are frequently used to perform:

- Calcination

- Reduction Roasting

- Incineration

- Thermal Desorption

- And more…

It is no surprise then, that with this flexibility, interest and research around applying high-temperature kilns in novel ways has become a growing trend. Through the comprehensive batch- and pilot-scale testing services offered in the FEECO Innovation Center, FEECO has been on the front lines of the development of many new concepts and processes, all centered around improving the world around us.

“Everything we’re seeing in the high-temp kiln market comes down to sustainability,” says Alex Ebben, FEECO Process Sales Engineer. “Every thermal project that comes through the door somehow ties back to making a process or product more sustainable, improving the reuse potential of a waste, or just reducing pollution in some way. It is very exciting to be working on these technologies first hand. These are the processes that are going to make tomorrow better for everyone.”

The Innovation Center utilizes a number of batch- and pilot-scale direct and indirect rotary kilns, paired with advanced automation, data collection, and reporting capabilities, to help customers take their concept from idea to fully realized, commercial-scale production.

Indirect-fired batch kiln used for testing in the FEECO Innovation Center

Some of the current ways in which rotary kilns are being applied in novel approaches to advance sustainability efforts are outlined here.

Production of Carbon Products

The production of carbon products has seen explosive growth in recent years. Hundreds of biomass waste materials such as manure, agricultural residuals, forest products, and more, are now being seen as raw materials for value-added products.

The transformation of such materials can create a marketable product from what was once a waste management challenge. These products also often boast additional environmental benefits as well. The carbon products gaining the most momentum are biochar and activated carbon. These products are created through the pyrolysis of biomass sources in a controlled environment.

Biochar

Biochar is a charcoal-like material with incredible potential. While it has principally been considered for use in soil restoration and crop production efforts, researchers are finding that it can offer a range of benefits in other settings as well. This includes potential use as an adsorbent in water treatment, a tool for limiting nitric oxide emissions from soil, and even improving the production of biomethane during anaerobic digestion, among many others.

Biochar looks to be a critical tool in reaching a more sustainable approach to solving many of today’s globally recognized problems.

Biochar (right) after pyrolyzing raw wood (left) in an indirect kiln in The FEECO Innovation Center.

Activated Carbon

Activated carbon is an upgraded product created in a similar pyrolysis process to biochar, with the addition of steam activation. A premium adsorbent with many applications in environmentally focused efforts, activated carbon has various uses in air pollution control and water treatment.

While activated carbon is a fairly established product, its application in new settings is calling for a deeper understanding of how this innovative material works. Biochar is a less established industry, with a fair amount of research and development around the material still needed.

Ebben, along with colleague, Michael Eidge, presented a paper at the Biochar 2018 conference regarding their work in developing a baseline of material characteristics correlated with process parameters around biochar. The paper was entitled, Critical Characteristics of Wood-based Biochar Correlated with the Pyrolysis Process in an Indirect Kiln.

For more information on these carbon products and how they are produced, see our article and infographic, The Thermal Conversion of Biomass to Activated Carbon (and Everything in Between).

Material Recovery & Recycling

Material recovery and recycling have also become a primary focus of sustainability efforts, as what were once viewed as wastes are now seen as potential sources of raw materials.

The very foundation of material recovery and recycling often centers around breaking a product down into its most simple components, or driving a chemical reaction or phase change that will convert it to a more useful or more amenable state. As such, many recovery and recycling processes would not be possible if not for high-temperature kilns.

The wealth of products that can be recovered from wastes or process by-products via thermal treatment in a high-temperature kiln is innumerable. Metals have been an area of particular interest, as finite resources dwindle in the face of booming demand.

Metal Recovery

Metal recovery, particularly as it relates to precious metals, has long been a subject of research, but in many cases, hasn’t been economically viable. However, as utilizing every potential resource has become ever-more essential, these processes are becoming increasingly mainstream.

Materials frequently explored for metal recovery via thermal processing in a high-temperature rotary kiln include:

- Electronic waste

- Fly ash

- Red mud

- And more

Red mud (bauxite tailings) samples produced during metal recovery testing using high temperature kilns in the FEECO Innovation Center

High-temperature kilns are also vital in the aluminum decoating process, which maximizes aluminum recycling capabilities by removing the myriad of lacquers and coatings applied to aluminum products for end product use.

Hydrocarbon Recovery

Rotary kilns are also employed in recovering other valuable resources from waste materials as well. In one case, FEECO assisted a company recovering hydrocarbons from spent drilling mud so they could be sold back to the market and the drilling mud reused.

The waste recovery system consisted of an indirect kiln with a specialized feeding system and custom internals to prevent material from sticking and causing buildup inside the unit. Read the project profile >>

Facilitating Sustainability

The above applications all utilize high-temperature kilns in a direct approach to improving sustainability. However, it’s important to recognize that they also play a critical role in an indirect capacity as well, helping to create many of the products that allow sustainable approaches to be realized. Two key examples of this are listed below.

Lithium from Spodumene

Lithium is the key component in lithium-ion batteries – the battery of choice in the electric vehicle movement. While lithium can also be derived from brines, processing from spodumene (a lithium ore) is gaining importance. The production of lithium from spodumene relies on high-temperature kilns to extract usable lithium components to feed the insatiable demand of the lithium-ion battery market.

Catalysts

Catalysts are far from a new concept, but their increasing applicability in improving process efficiency and making reactions possible makes them ever-more important in sustainability efforts.

Research and development around catalysts is a rising trend, with many new catalysts hitting the market. Catalysts can reduce energy requirements, decrease environmental impact, and aid in the creation of critical products and materials that subsequently contribute to more sustainable processes.

In his recent article, Reaction: Opportunities for Sustainable Catalysts for Chem Journal, Patrick Holland argues that catalysts are a fundamental part of achieving a more sustainable society: “This is where catalysis plays an important role, because studies in catalysis uncover new reaction pathways for chemical transformations of both known resources and unknown resources (including waste).”1

Recent research around catalysts has seen a focus on managing greenhouse gasses in the fight against climate change – particularly when it comes to carbon dioxide.

Many catalysts would not be possible without high-temperature kiln technology.

High-Temperature Kilns: The Thermal Processing Device of Choice

Thermal processing can be carried out using a variety of devices depending on the requirements of the process. In addition to their flexibility in application, rotary kilns offer several advantages over other types of equipment as well, making them the preferred choice for many industrial processors.

Kilns are also based on proven rotary drum technology, which makes them incredibly reliable, often lasting for decades when properly maintained.

As well as offering significant opportunity for customization, they are also relatively low maintenance and simple to operate, particularly when they are equipped with an automation and control system.

Conclusion

As existing processes are applied to new materials, and researchers work on novel processes to solve a myriad of issues, high-temperature kilns will continue to prove crucial to achieving a more sustainable society.

FEECO is the industry leader in developing advanced thermal processing technologies and manufacturing the custom rotary kilns needed to bring them to market. For more information on our feasibility or pilot testing, or our custom rotary kilns, contact us today!

SOURCES:

- Holland, Patrick L. “Reaction: Opportunities for Sustainable Catalysts.” Science Direct, Chem, 13 Apr. 2017, www.sciencedirect.com/science/article/pii/S2451929417301304.